Marine microbubble generating device

A micro-bubble generation and bubble technology, which is applied in ship hull, hull design, ship construction, etc., can solve the problems of large jet resistance, large bubble diameter, and increased power consumption of the blower, so as to reduce difficulty, ensure stability, and improve drag reduction. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

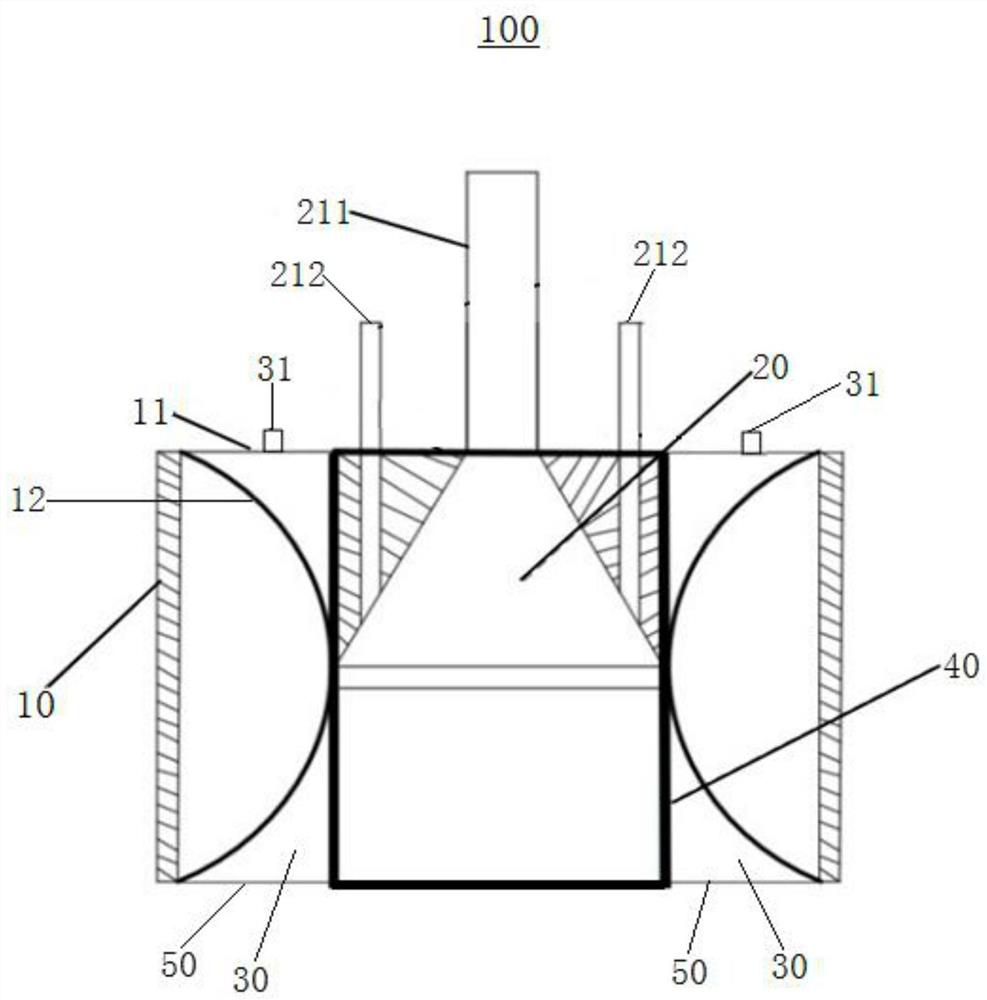

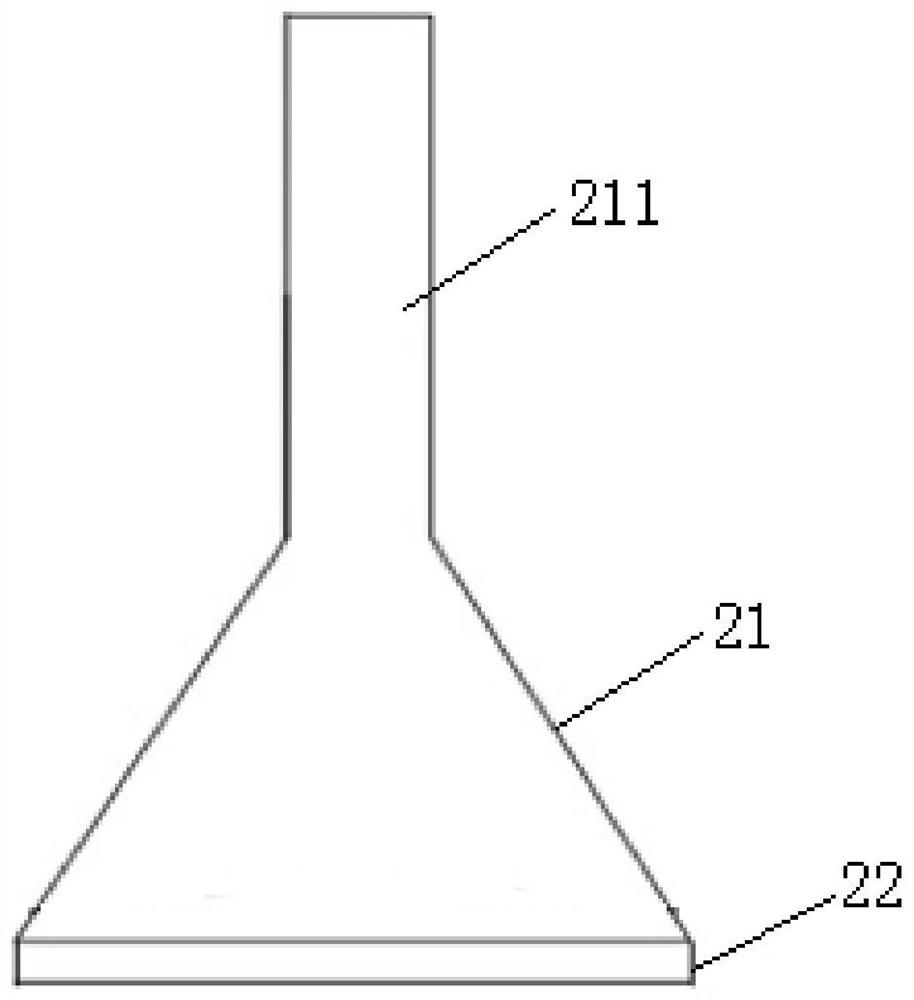

[0025] Such as Figure 1-2 As shown, a microbubble generating device 100 provided by the present invention includes a casing 10 , a gas channel 20 rotatably installed in the casing 10 , and a cover 40 . The upper end of the housing 10 is provided with an end cap 11 for sealing, the lower end is a bubble nozzle 50 connected to the outside, and the inner side of the housing 10 is provided with an inwardly protruding arc-shaped wall 12 . The gas flow channel 20 includes a variable diameter wall surface 21 whose diameter gradually increases along the gas flow direction and an equal diameter wall surface 22 arranged at the lower end of the variable diameter wall surface 21. There are exhaust holes 221 , and the equal-diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com