Packaging tube structure for packaging micro-mini integrated circuits

A technology for integrated circuits and packaging tubes, which is applied in the field of packaging tube structures for packaging micro-miniature integrated circuits to prevent interlacing with each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

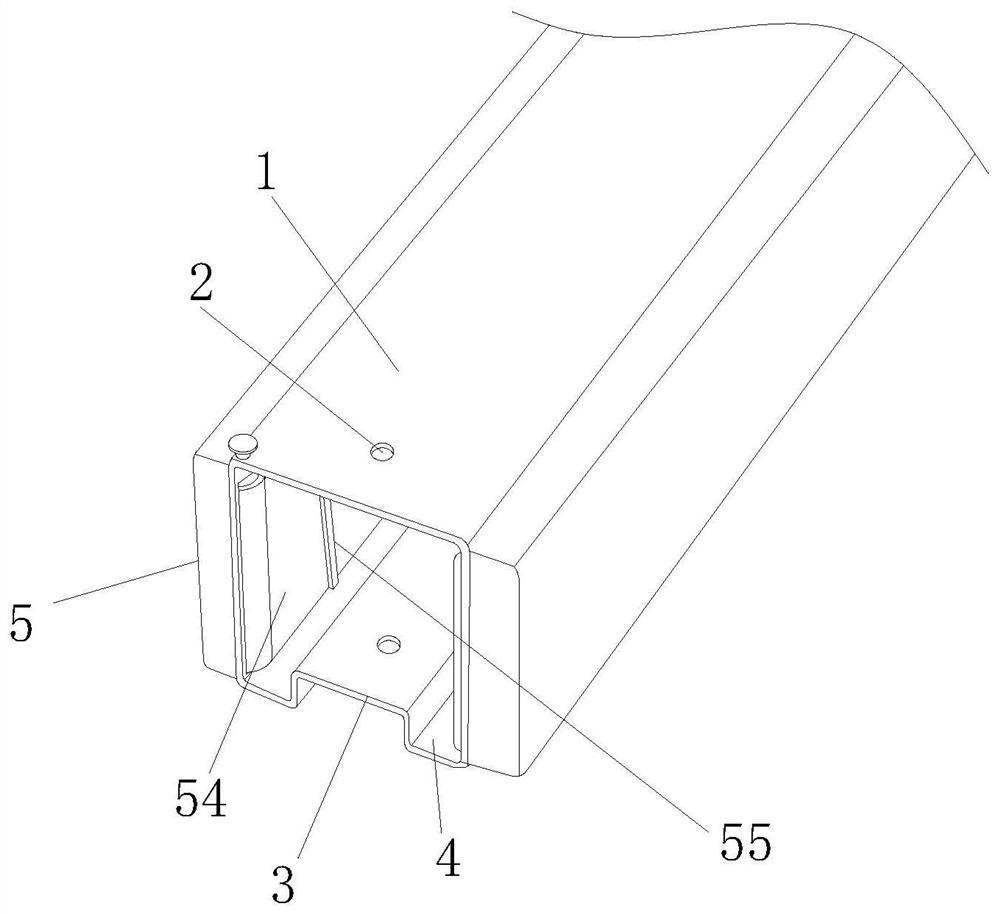

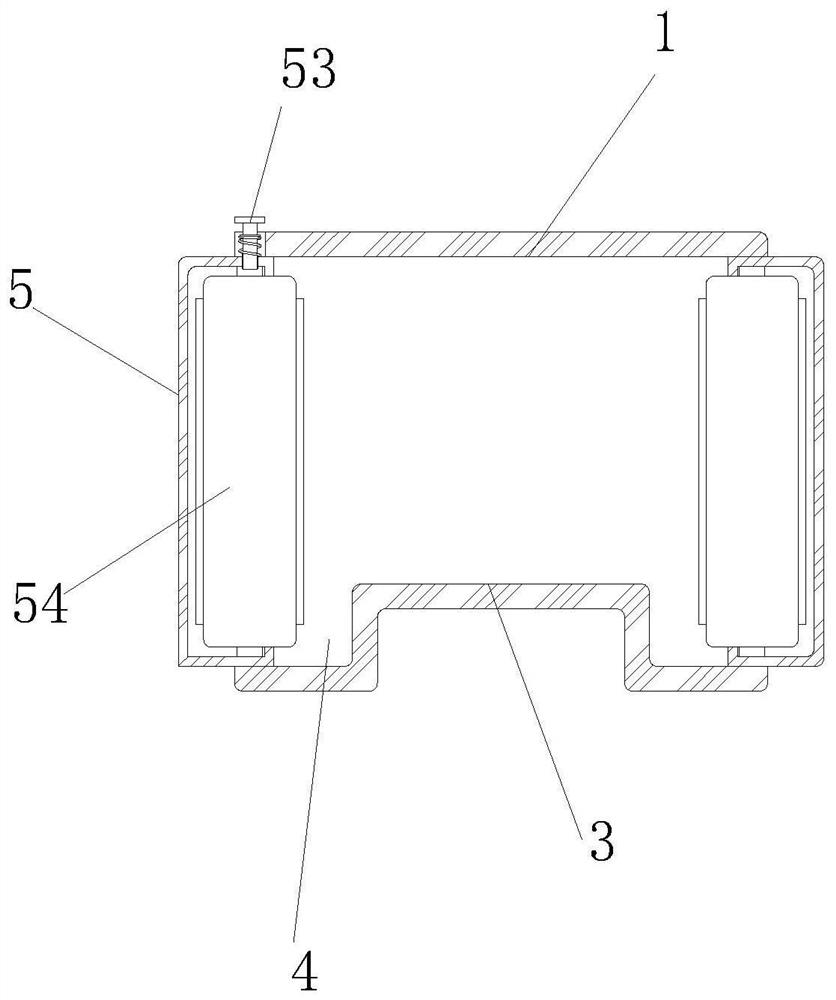

[0029] see figure 1 and figure 2 , the present invention provides a packaging tube structure for packaging micro-integrated circuits through improvement, including a tube body 1, a fixing hole 2, a guide rail 3, a chute 4 and a separation guide mechanism 5, and the front end of the tube body 1 is opposite to the upper and lower sides. A fixing hole 2 is provided, and the separation guide mechanism 5 is installed and fixed on the inner left end of the pipe body 1 and is fixedly connected.

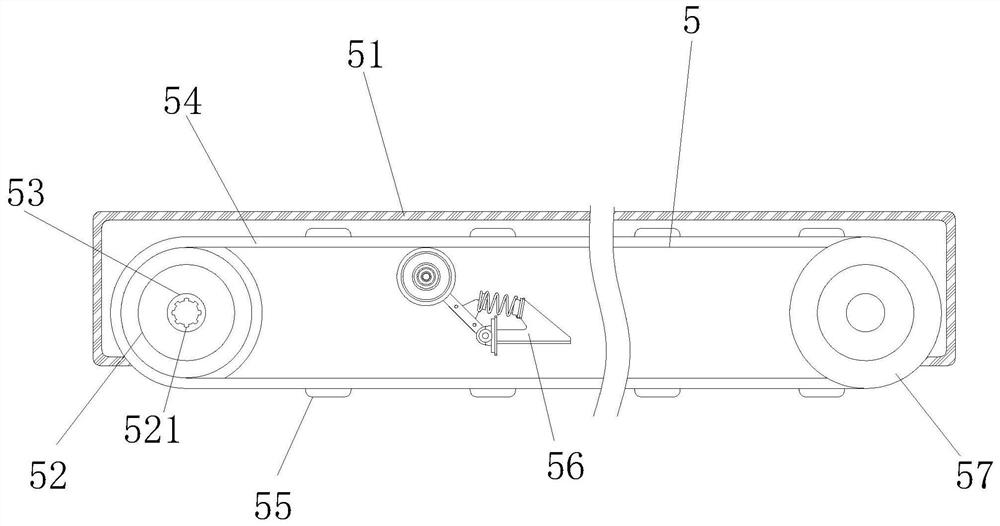

[0030] see image 3 , the present invention provides a packaging tube structure for packaging micro-integrated circuits through improvement. The separation guide mechanism 5 includes a fixed frame 51, a first runner 52, a rotating mechanism 53, a belt 54, a dividing plate 55, and a tensioning mechanism 56. And the second runner 57, the fixed frame 51 is fixedly connected with the inner left end of the pipe body 1, the first runner 52 is connected with the inner left end of the fixed frame...

Embodiment 2

[0034] The present invention provides a packaging tube structure for packaging micro-miniature integrated circuits through improvement. The center lines of the knob 531, the rotating shaft 532, the limit block 533 and the return spring 534 are in the same vertical direction, which is beneficial to make the rotating shaft 532 For the function of smooth rotation, a groove 521 is provided in the middle of the first runner 52 , and the protrusion 535 is embedded inside the groove 521 , which is beneficial to drive the first runner 52 to rotate.

[0035] The present invention provides a packaging tube structure for packaging micro-miniature integrated circuits through improvement, and its working principle is as follows;

[0036] First, before use, the packaging tube structure for packaging micro-miniature integrated circuits is placed horizontally, so that the tube body 1 can fix and support the packaging tube structure;

[0037]Second, when in use, the integrated circuits are pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com