Automatic PCB feeding and discharging machine

A technology for automatic loading and unloading of PCB boards, applied to conveyors, conveyor objects, laminated printed circuit boards, etc., can solve the problems of small size and ineffective transportation of PCB automatic loading and unloading machines, and achieve convenient manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

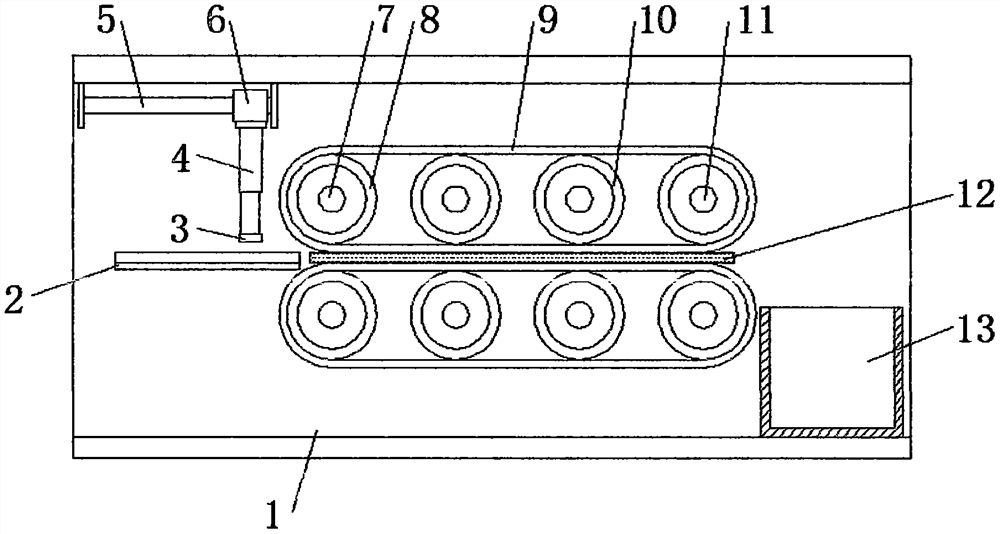

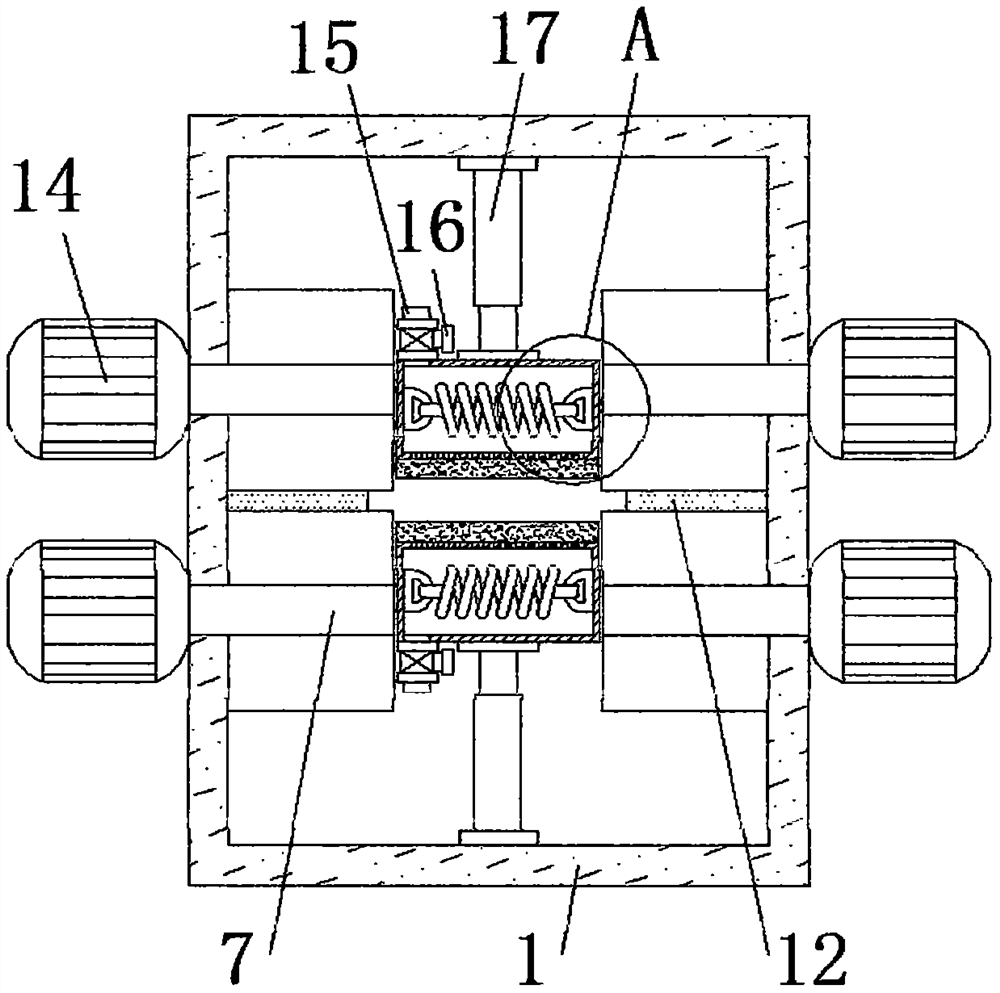

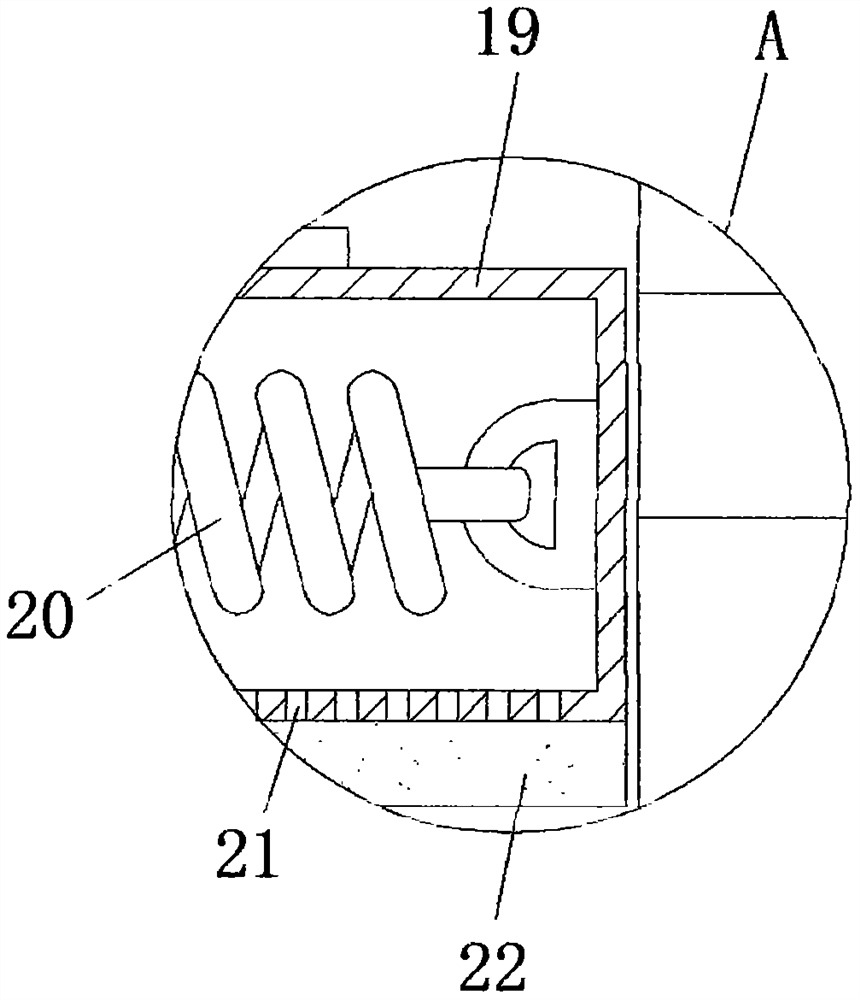

[0027] refer to Figure 1-4 , a PCB board automatic loading and unloading machine, comprising a fixed frame 1, one side of the top inner wall of the fixed frame 1 is provided with a push mechanism, two motors 14 and four motors 14 are fixed on the outer walls of both sides of the fixed frame 1 by bolts One end of the output shaft is connected with a transmission shaft 7 by a key, and one end of the four transmission shafts 7 is located inside the fixed frame 1, and the peripheral outer wall of the transmission shaft 7 is sleeved with a driving wheel 8, and the inner walls of both sides of the fixed frame 1 are provided with A plurality of rotating shafts 11 are plugged in, and the rotating shafts 11 and the transmission shaft 7 are located on the same horizontal line, auxiliary wheels 10 are sleeved on the outer peripheral walls of the rotating shafts 11, and a conveyor belt 9 is sleeved on the outer walls of the driving wheel 8 and the auxiliary wheels 10, There is a gap betw...

Embodiment 2

[0032] refer to Figure 5 , an automatic loading and unloading machine for PCB boards. Compared with Embodiment 1, this embodiment is fixed with a fixed plate 23 by bolts on one side of the fixed frame 1, and an air suction pump is fixed by bolts on one side of the outer wall of the fixed plate 23. 24. The output end of the air pump 24 is facing the conveyor belt 9, and the air pump 24 is located above the collection tank 13.

[0033] During use, when the PCB board is out of the range of the conveyor belt 9, start the air pump 24 to pump air, so as to facilitate the discharging of the PCB board and ensure that the PCB board can stably fall into the collection tank 13 inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com