Tower crane capable of preventing material from shaking

A technology for tower cranes and materials, applied in the direction of load hanging components, safety devices, cranes, etc., can solve problems such as easy shaking, component impact, and inability to effectively prevent objects from falling off, so as to avoid excessive impact force and improve work efficiency , good anti-shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

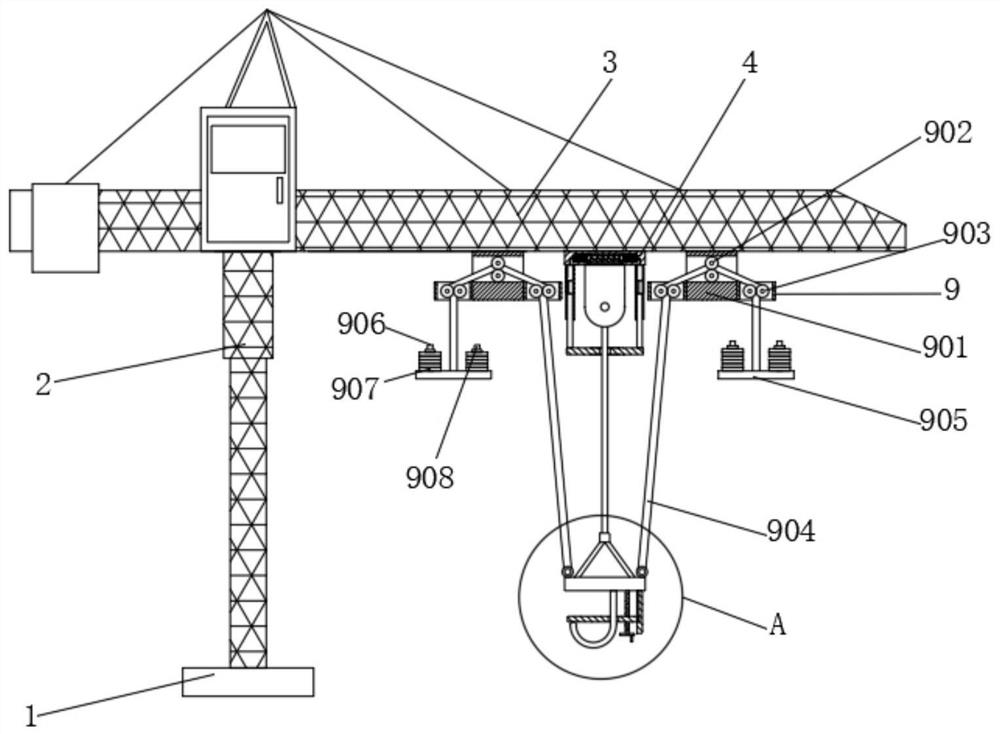

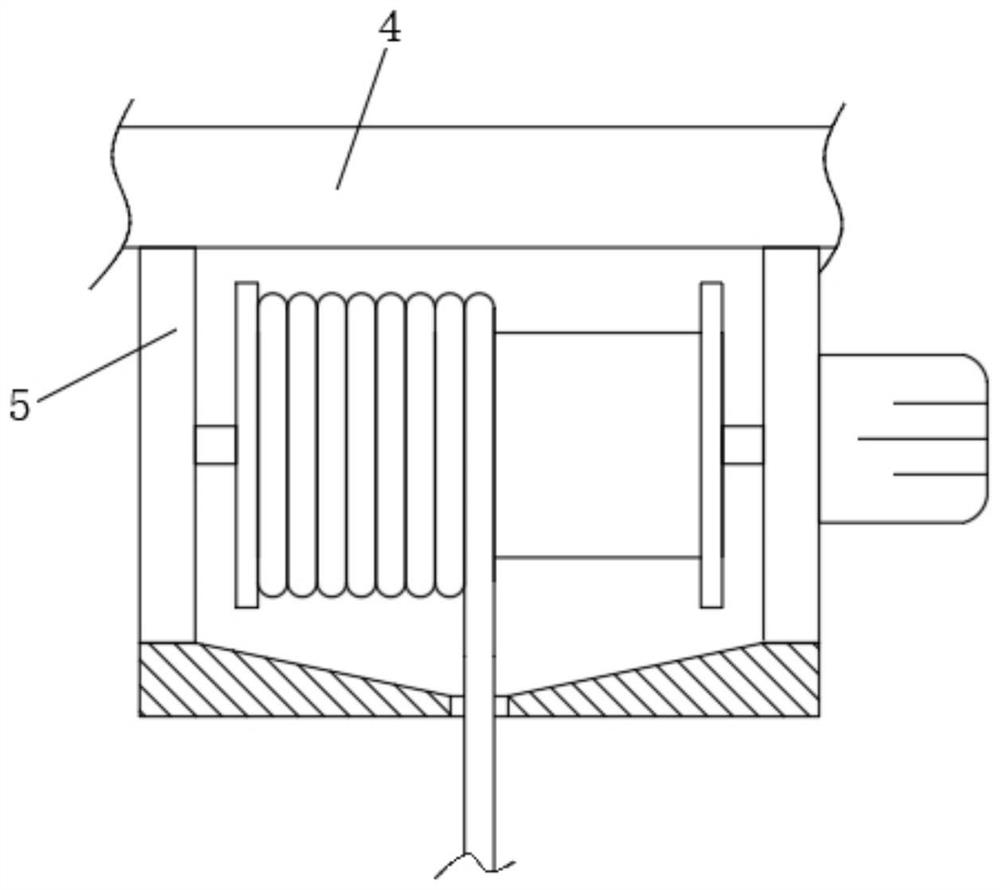

[0024] refer to Figure 1-4 , a tower crane capable of preventing materials from shaking, including a base 1, a tower body 2, a boom 3, a fixing seat 4, a connecting block 5, a lifting rope 6, a hanger 7, a hook 8, an anti-swaying mechanism 9, T Type seat 901, guide wheel 1 902, guide wheel 2 903, guide rope 904, bearing seat 905, stud 906, counterweight 907, fastening nut 908, anti-collision mechanism 10, fixed outer rod 1001, telescopic inner rod 1002 , anti-collision plate 1003, fixed cylinder 1004, piston rod 1005, movable block 1006, compression spring 1007, inflatable air bag 1008, connecting pipe 1009, anti-falling mechanism 11, support plate 1101, anti-falling plate 1102, screw rod 1104 and hand wheel 1105 , the top of the base 1 is fixed with a tower body 2, the top of the tower body 2 is fixed with a boom 3, the bottom of the boom 3 is fixed with a fixing seat 4, and both sides of the bottom of the fixing seat 4 are fixed with connecting blocks 5, Between the two co...

Embodiment 2

[0027] refer to figure 1 and 4 The anti-sway mechanism 9 includes two T-shaped seats 901 fixed on the bottom of the boom 3, the two T-shaped seats 901 are respectively located on both sides of the fixed seat 4, and two T-shaped seats 901 are provided with through grooves 1, The inner wall of the through groove 1 is rotatably connected with two guide wheels 902, and both sides of the through groove 1 are provided with the through groove 2 on the T-shaped seat 901, and the inner wall of the through groove 2 is rotatably connected with two guide wheels. Two 903, load-bearing base 905 is installed under the two T-shaped seats 901, a guide rope 904 is fixed at the center of the top of the load-bearing base 905, and the other end of the guide rope 904 passes through a pair of guide wheels 903 and a pair of guide wheels One 902 passes through another pair of guide wheels two 903, and is hinged with the top of the hanger 7. Both sides of the guide rope 904 are provided with studs 906...

Embodiment 3

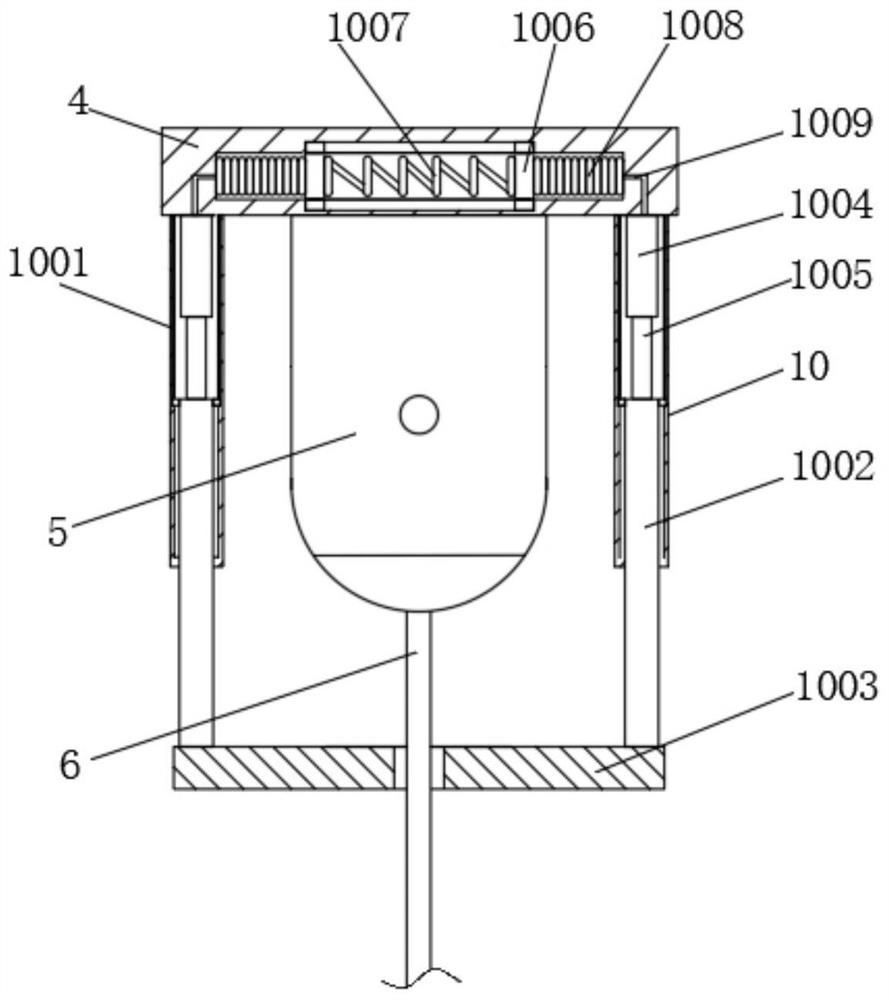

[0030] refer to figure 2, the anti-collision mechanism 10 includes fixed outer rods 1001 fixed on both sides of the bottom of the fixed base 4, the inside of the fixed outer rods 1001 is slidingly connected with telescopic inner rods 1002, and the bottoms of the two telescopic inner rods 1002 are fixed with anti-collision plates 1003, fixed The inside of the outer rod 1001 is provided with a telescopic passage matched with the telescopic inner rod 1002. A fixed cylinder 1004 is fixed on the inner top wall of the telescopic passage. The inner sliding and sealing connection of the fixed cylinder 1004 is connected with a piston rod 1005. One end of the piston rod 1005 is connected to the The tops of the telescopic inner rods 1002 are connected, and the inside of the fixed seat 4 is provided with an inner cavity, and two movable blocks 1006 are slidably connected to the inner cavity, and a compression spring 1007 is fixed between the opposite sides of the two movable blocks 1006. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com