Positioning limit type oil filter

An oil filter and filter element technology, which is applied in the fields of filtration and separation, mechanical equipment, engine components, etc., can solve problems such as unfavorable installation coordination and position limit, unfavorable automatic production requirements, insufficient support force of filter element components, etc., to achieve convenient Assembly, positioning function enhancement, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below with reference to the drawings and embodiments.

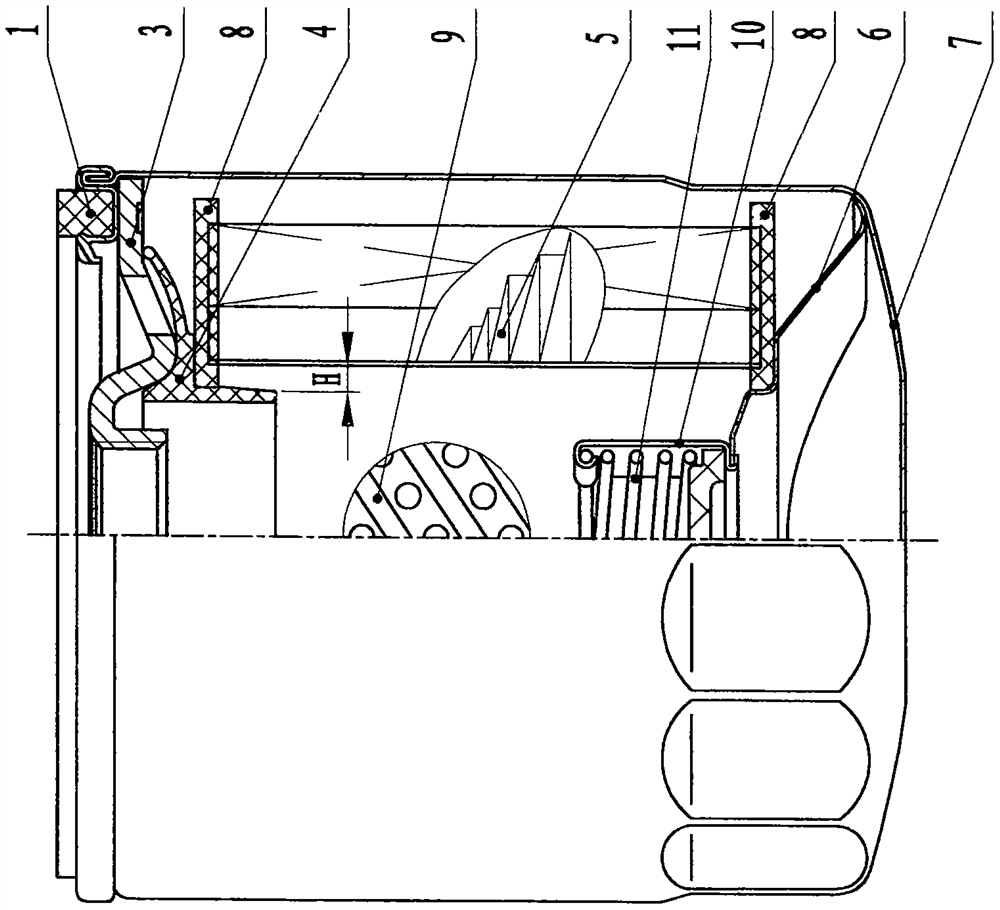

[0009] refer to figure 1 It can be seen that the position-limiting oil filter of the present invention includes a housing 7, a screw plate 3 (including a screw plate and a close plate), a filter element assembly, and a bypass valve assembly. The filter element assembly consists of a filter element end cover 8 (including an upper The filter element end cover and the lower filter element end cover), filter paper 5, and center pipe 9. The bypass valve assembly is composed of a bypass valve seat 10 (which already contains a bypass valve) and a bypass valve spring 11. The screw A check valve 4 is installed between the dense plate 3 and the (upper) filter element end cover 8 of the filter element assembly. The distance H between the side of the check valve and the filter paper gradually increases from top to bottom, which is beneficial to the assembly of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com