Slide upright semi-immersion fixed type constant-temperature dyeing bin unit and dyeing machine

A fixed, glass slide technology, applied in the field of dyeing, can solve problems such as easy blockage of drain holes, and achieve the effect of avoiding contamination of the equipment table.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0031] Embodiments of the invention:

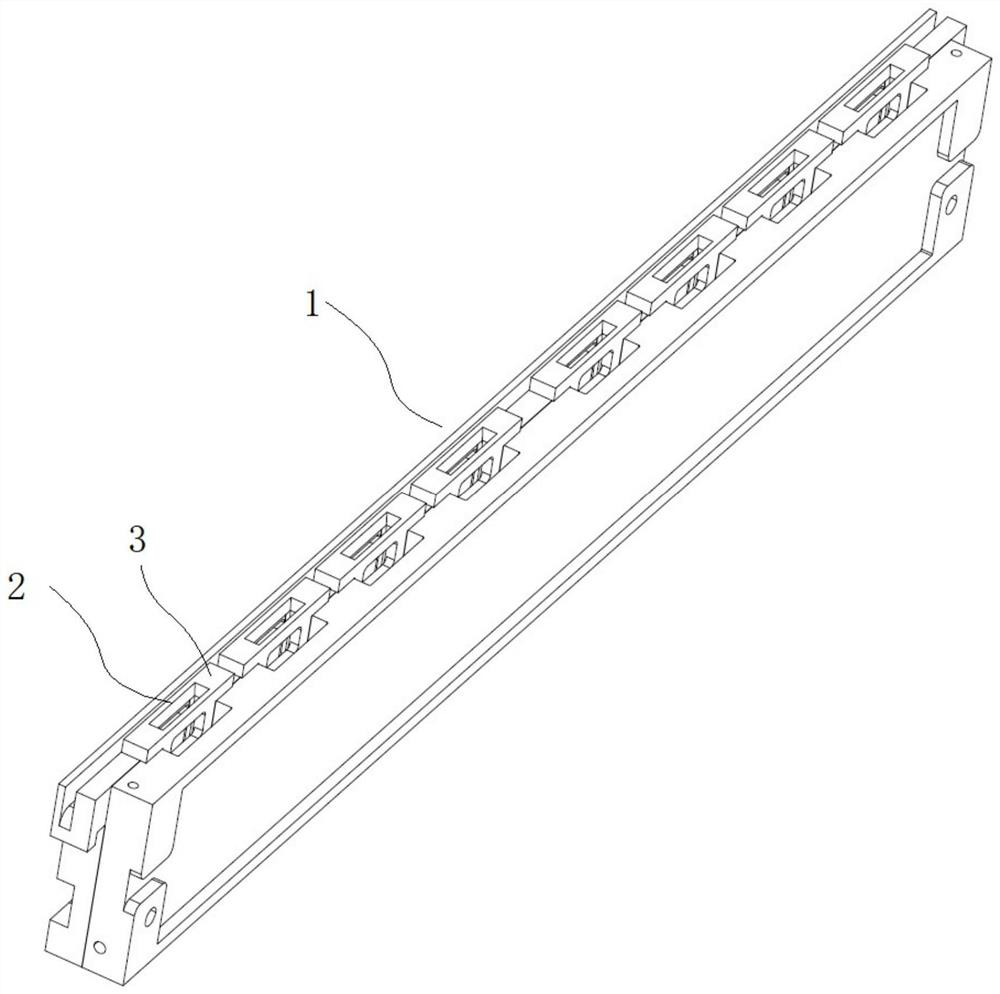

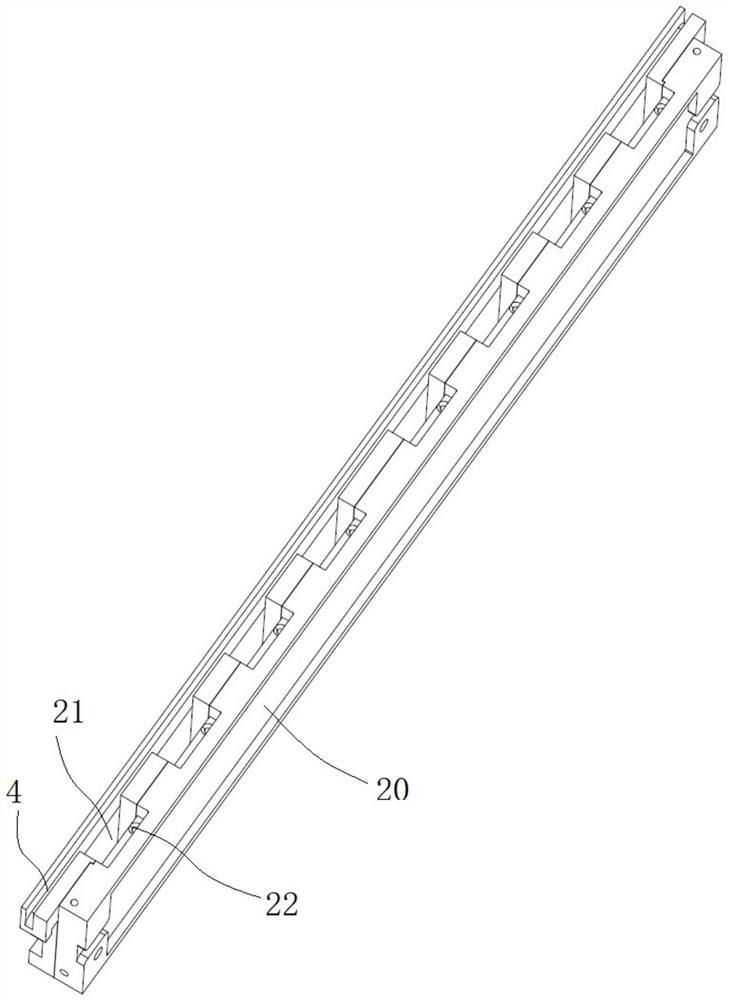

[0032] Figures 1 to 7 As shown, a glass slide upright semi-immersion fixed constant temperature staining chamber unit 2 includes a staining chamber 21, the bottom of the staining chamber 21 is provided with a liquid inlet and discharge hole 23, and a slide cover 3 is inserted in the staining chamber. The slide holder 3 has a slide chamber 32 with an upper opening for inserting or taking out slides along the up-down direction. figure 1 Shown is a dyeing structural unit 1, which is provided with a row of eight constant temperature dyeing chamber units 2 in total.

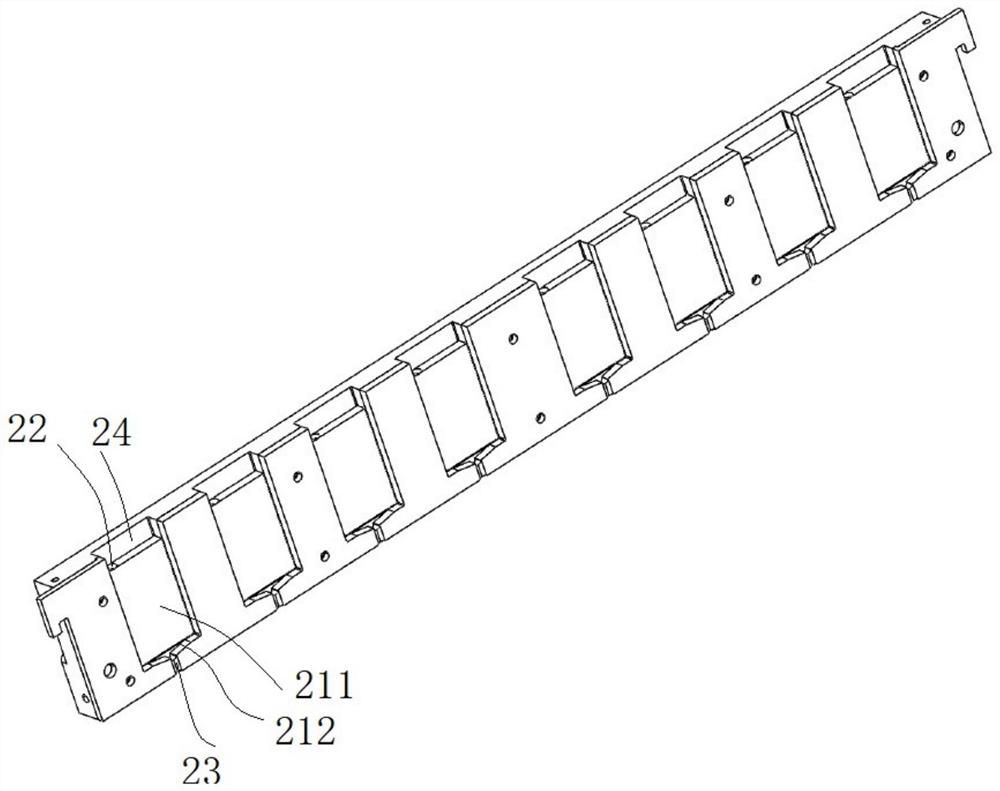

[0033] The staining chamber 21 is composed of a rectangular socket 211 matched with the slide cover and a V-shaped groove 212 at the bottom, and the liquid inlet and discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com