External pressure resistance quality detection device and operation method thereof

A detection device, quality technology, applied in the direction of measuring device, testing material strength using applied stable tension/pressure, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

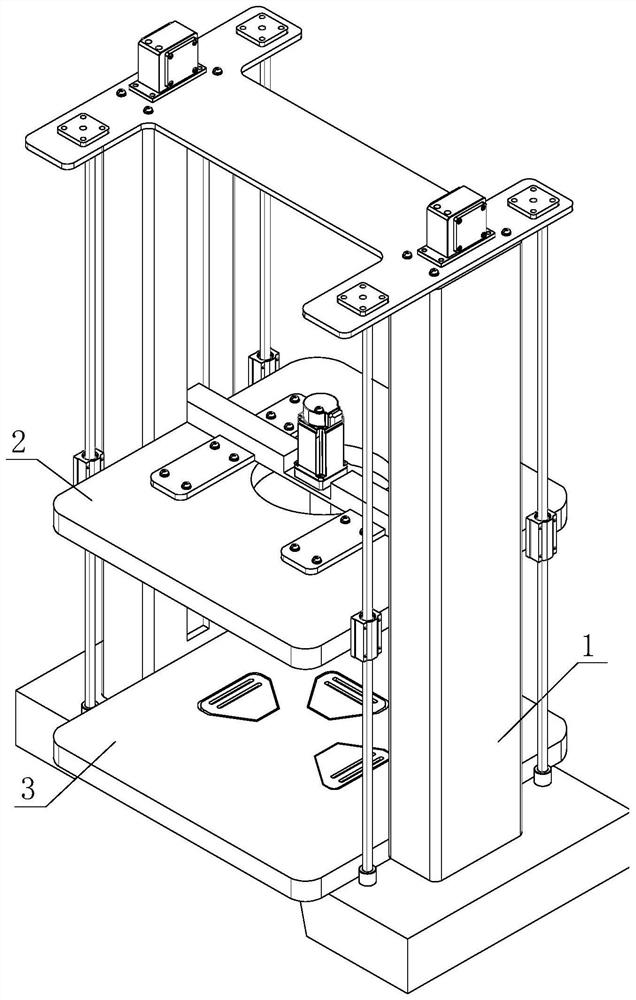

[0035] see figure 1 , an anti-external pressure quality detection device, including a detection fixed support mechanism 1, a platen mechanism 2 and a bottom plate mechanism 3.

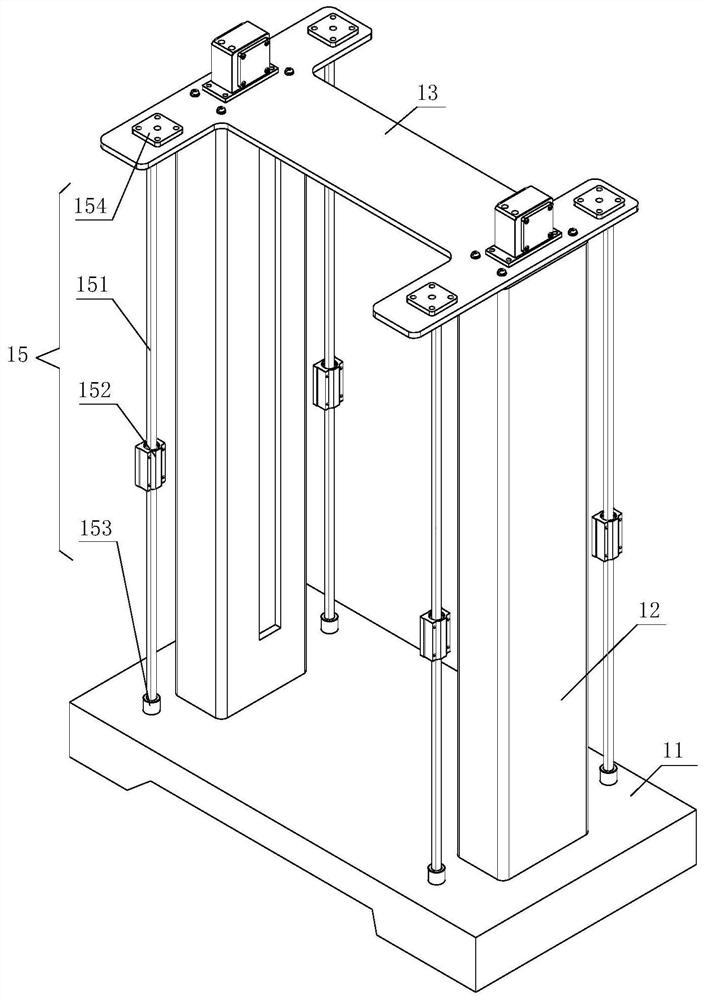

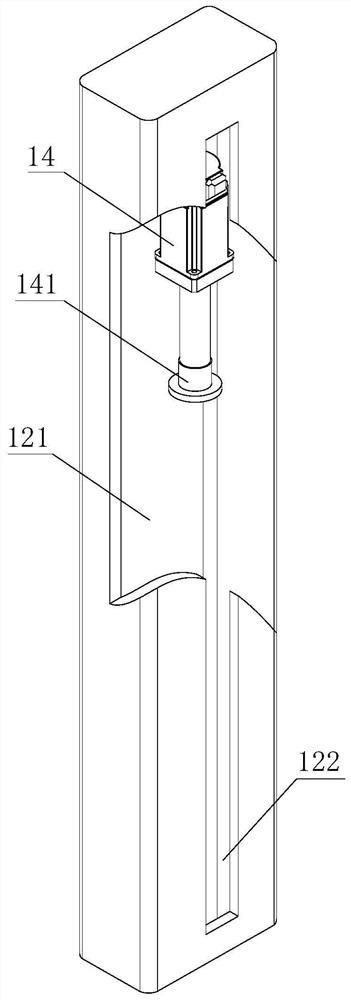

[0036] see Figure 2-3, the detection fixed support mechanism 1 is provided with a fixed base 11, a support member 12, a steel sheet 13, a first air cylinder 14 and a positioning member 15, and the upper end surface of the fixed base 11 is fixed with a welded support member 12 on both sides, and the upper end of the support member 12 is fixed. The steel plate 13 is installed, the first pneumatic cylinder 14 is fixedly installed inside the support member 12, the two ends of the positioning member 15 are respectively fixedly welded on the upper end surface of the fixed base 11 and the lower end surface of the two ends of the steel plate 13, and the support member 12 is provided with an inner The installation cavity 121 and the notch 122, the inner installation cavity 121 is opened in the inside of the s...

Embodiment approach

[0039] In order to further better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method of operating an anti-external pressure quality detection device, which is characterized in that it includes the following steps:

[0040] S01: horizontally place the carton to be detected on the fixed bottom plate 31;

[0041] S02: The first air cylinder 14 drives the pressure plate 21 to move down to press down the carton placed on the fixed bottom plate 31, or the first air cylinder 14 drives the pressure plate 21 to move down to a certain position from the upper end of the carton and then close the first air pressure Cylinder 14, start the second pneumatic cylinder 23, the second pneumatic cylinder 23 drives the auxiliary circular pressure plate 231 to move down, and the carton placed on the fixed base plate 31 is pressed down;

[0042] S03: record the pressure value when the carton starts to deform and when the carton is completely deformed...

Embodiment 2

[0045] see figure 1 and Figure 6 , an anti-external pressure quality detection device, including a detection fixed support mechanism 1, a platen mechanism 2 and a bottom plate mechanism 3.

[0046] see Figure 2-3 , the detection fixed support mechanism 1 is provided with a fixed base 11, a support member 12, a steel sheet 13, a first air cylinder 14 and a positioning member 15, and the upper end surface of the fixed base 11 is fixed with a welded support member 12 on both sides, and the upper end of the support member 12 is fixed. The steel plate 13 is installed, the first pneumatic cylinder 14 is fixedly installed inside the support member 12, the two ends of the positioning member 15 are respectively fixedly welded on the upper end surface of the fixed base 11 and the lower end surface of the two ends of the steel plate 13, and the support member 12 is provided with an inner The installation cavity 121 and the notch 122, the inner installation cavity 121 is opened in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com