Short-circuit connector

A connector and short-circuit technology, which is applied in the direction of connection, connecting device parts, contact parts, etc., can solve the problems of short-circuit connectors without a waterproof sealing structure, difficult installation, time-consuming and labor-intensive, etc., and achieve a good waterproof sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

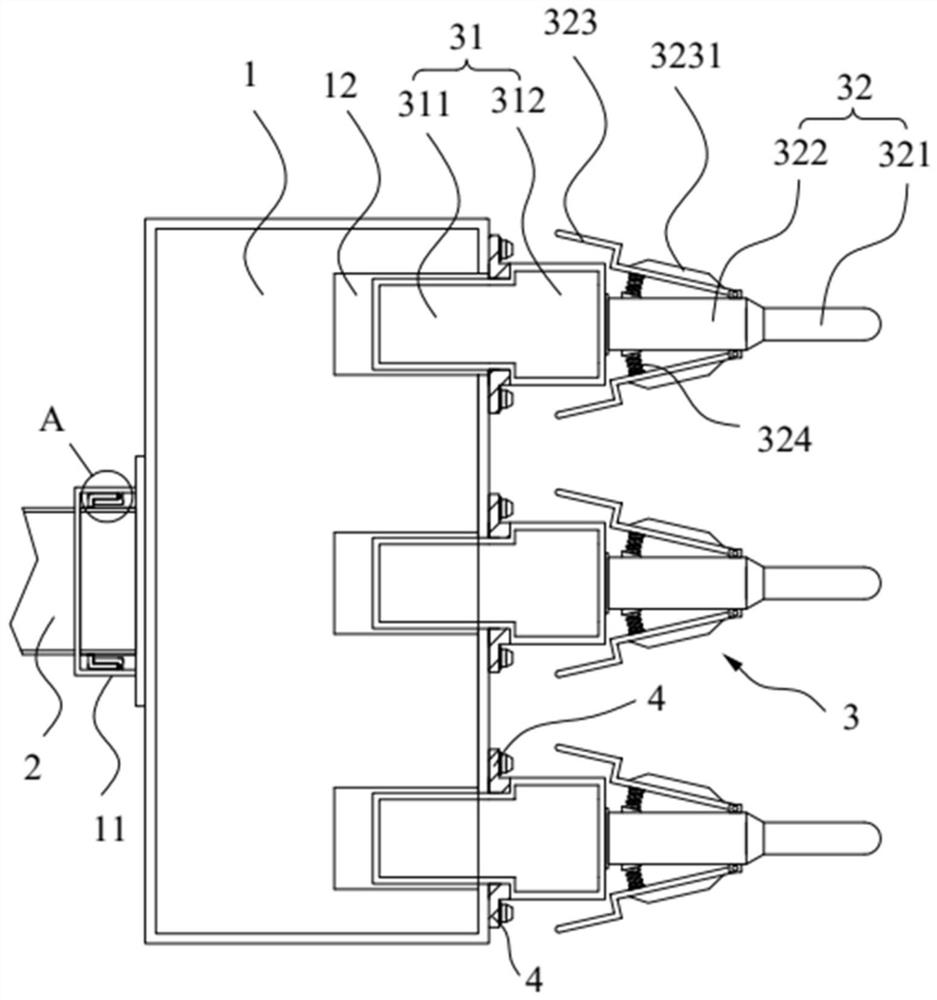

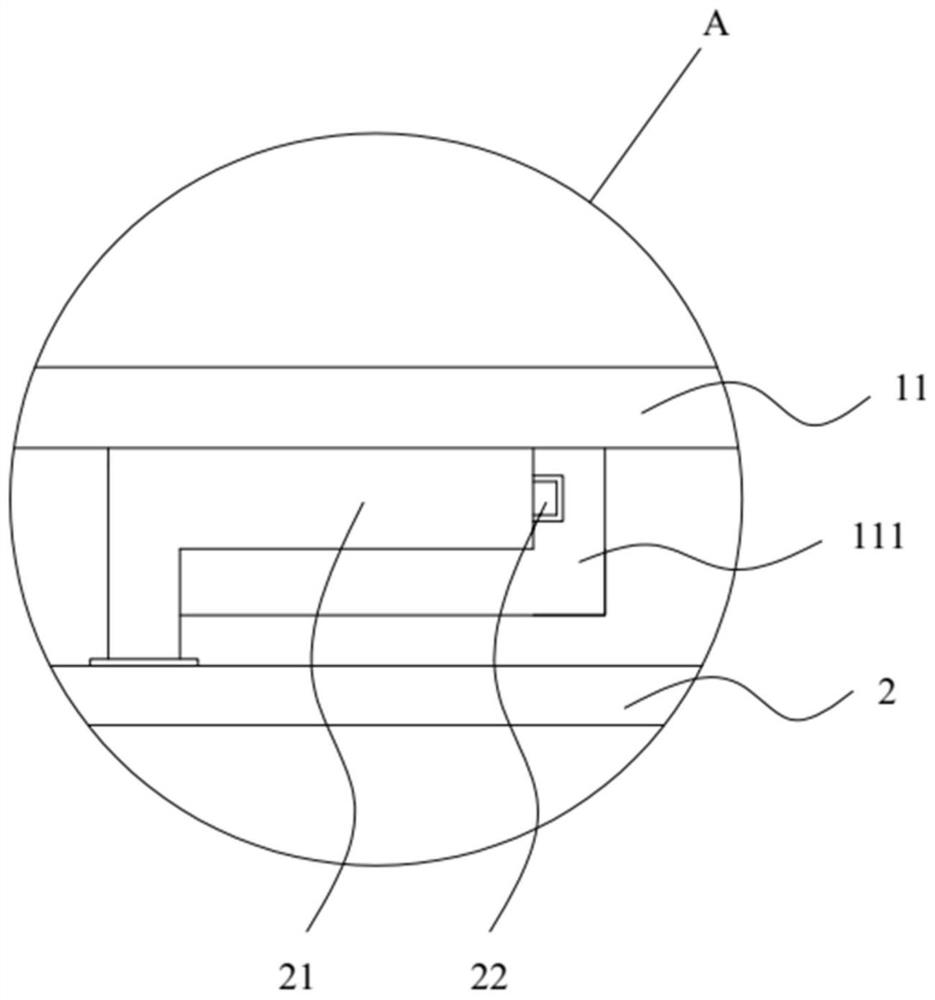

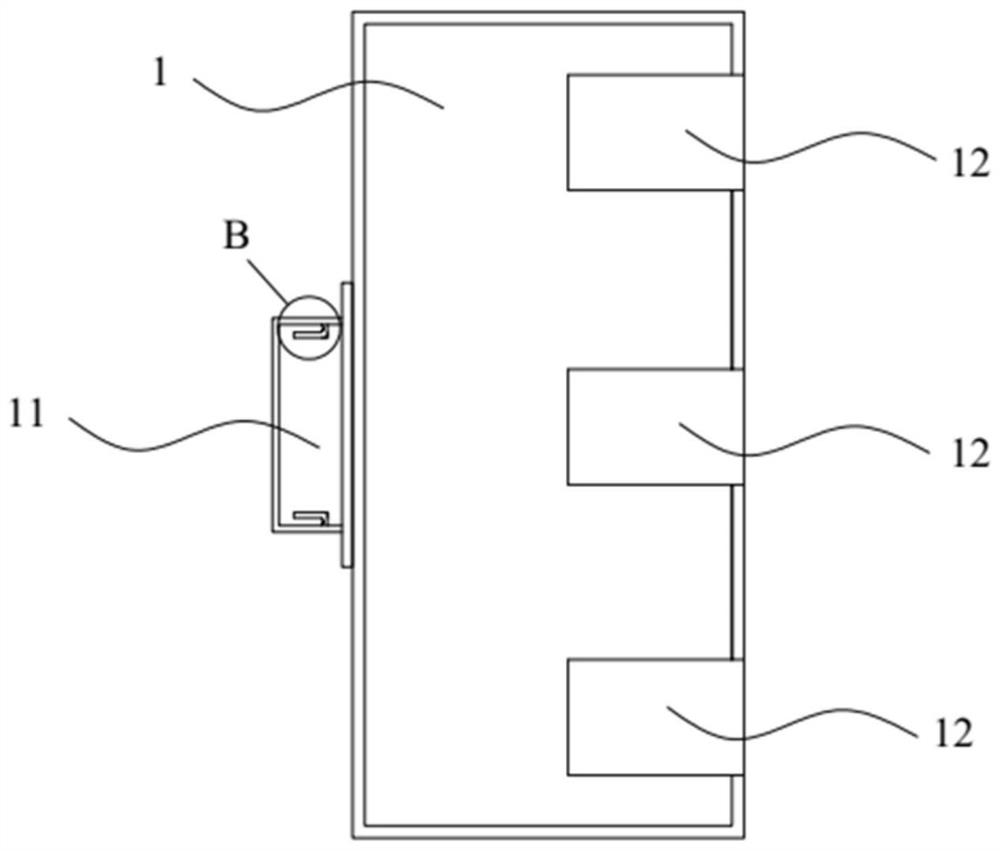

[0041] Such as Figure 1-Figure 4 As shown, this embodiment discloses a shorting connector, including a connecting portion 1 , a shorting terminal 3 and at least two fixing structures 4 . The connection part 1 has a connection port 11 and a plurality of positioning grooves 12 , and the connection port 11 is connected with a connector 2 . The inner wall ring of the connection port 11 is provided with a bending structure 111 , together with the bending structure 111 to form a first waterproof groove 110 , the bottom of the first waterproof groove 110 has a second waterproof groove 120 . The joint 2 has a first plug-in 21 adapted to the first waterproof groove 110, the first plug-in 21 is provided with a second plug-in 22, the first plug-in 21 is plugged into the first waterproof groove 110, and the second plug-in 22 is plugged into the in the second waterproof groove 120 . The shorting terminal 3 includes a connected insulating post 31 and a pin 32 , the insulating post 31 is ...

Embodiment 2

[0058] The structure of the short-circuit connector disclosed in this embodiment is basically the same as that of the short-circuit connector in Embodiment 1, except that:

[0059] The insulating column 31 of the short-circuit terminal 3 is formed by connecting multiple coaxial columns. In the direction in which the insulating pillars 31 , the conductive cylinders 322 and the main body 312 are arranged, the areas of the radial cross-sections of the plural pillars gradually become larger and form a stepped axis. The insulating column 31 has a plurality of second stepped surfaces 313 that can be in contact with the fixed structure 4. According to different shorting requirements, only the shorting terminal 3 needs to be plugged into the positioning groove 12 on the selected connecting part 1. One of the plurality of second stepped surfaces 313 on the insulating post 13 abuts against the fixing structure 4 on the connecting portion 1 to assemble and form a required short-circuit c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com