Oil agent-containing silicone elastomer particle and use thereof in cosmetic composition, etc.

A technology of silicone elastomer and silicone composition, which is applied in the directions of medical preparations, cosmetics and cosmetics containing active ingredients, can solve the problems of handling workability, storage stability, insufficient preparation stability, inability to prepare mixtures, disperse Insufficient and other problems, to achieve the effect of excellent preparation stability, excellent storage stability, and excellent feeling of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0231] [Example 1: C6 crosslinked silicone elastomer particles containing 33% of oil agent 1]

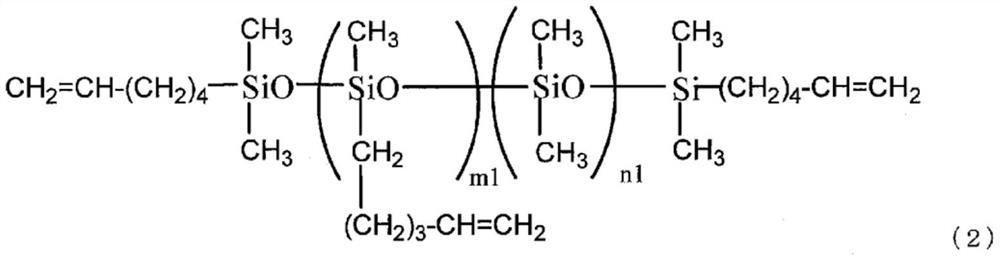

[0232] The polyorganosiloxane represented by the average formula [Chem. 1-2] and the polyorganosiloxane represented by the average formula [Chem. 2-1] were uniformly mixed at room temperature at a mass ratio of 89:11, and further, The oil agent 1 was added and mixed in an amount of 33% of the whole composition (that is, the oil agent content in the silicone elastomer particles containing the oil agent after hardening was 33%) and mixed to obtain Reactive compositions. Next, this composition was dispersed in an aqueous solution at 25° C. consisting of 3.0 parts by mass of polyoxyethylene alkyl (C12-14) ether and 20 parts by mass of pure water, and after being uniformly emulsified by a colloid mill, pure 350 parts by mass of water was diluted to prepare an emulsion containing the crosslinking reactive silicone emulsified particles composed of the above crosslinking reactive silicone ...

Embodiment 2

[0233] [Example 2: C6 crosslinked silicone elastomer particles containing 40% of oil agent 1]

[0234] The oil agent 1 was added in an amount of 40% of the whole composition (that is, the oil agent content in the silicone elastomer particles containing the oil agent after hardening became 40%), and in addition, Silicone elastomer particles containing an oil agent were obtained in the same manner as in Example 1. Table 1 shows physical properties such as JIS-A hardness of the obtained oil-containing silicone elastomer particles.

Embodiment 3

[0235] [Example 3: C6 crosslinked silicone elastomer particles containing 30% of oil agent 1]

[0236] The polyorganosiloxane represented by the average formula [Chem. 1-1] and the polyorganosiloxane represented by the average formula [Chem. 2-1] were uniformly mixed at room temperature at a mass ratio of 89:11, and further, The oil agent 1 was added and mixed in an amount of 33% of the whole composition (that is, the oil agent content in the silicone elastomer particles containing the oil agent after hardening was 33%) and mixed to obtain Reactive compositions. Next, this composition was dispersed in an aqueous solution at 25° C. consisting of 3.0 parts by mass of polyoxyethylene alkyl (C12-14) ether and 20 parts by mass of pure water, and after being uniformly emulsified by a colloid mill, pure 350 parts by mass of water was diluted to prepare an emulsion containing the crosslinking reactive silicone emulsified particles composed of the above crosslinking reactive silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap