Efficient multi-plate-body synchronous positioning type cavity preparation process

A technology of synchronous positioning and plate body, applied in the field of mechanical processing, can solve the problems of unguaranteed welding accuracy, cumbersome processing steps, unreliable positioning of spot welding, etc., and achieve the effect of ensuring the preparation accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

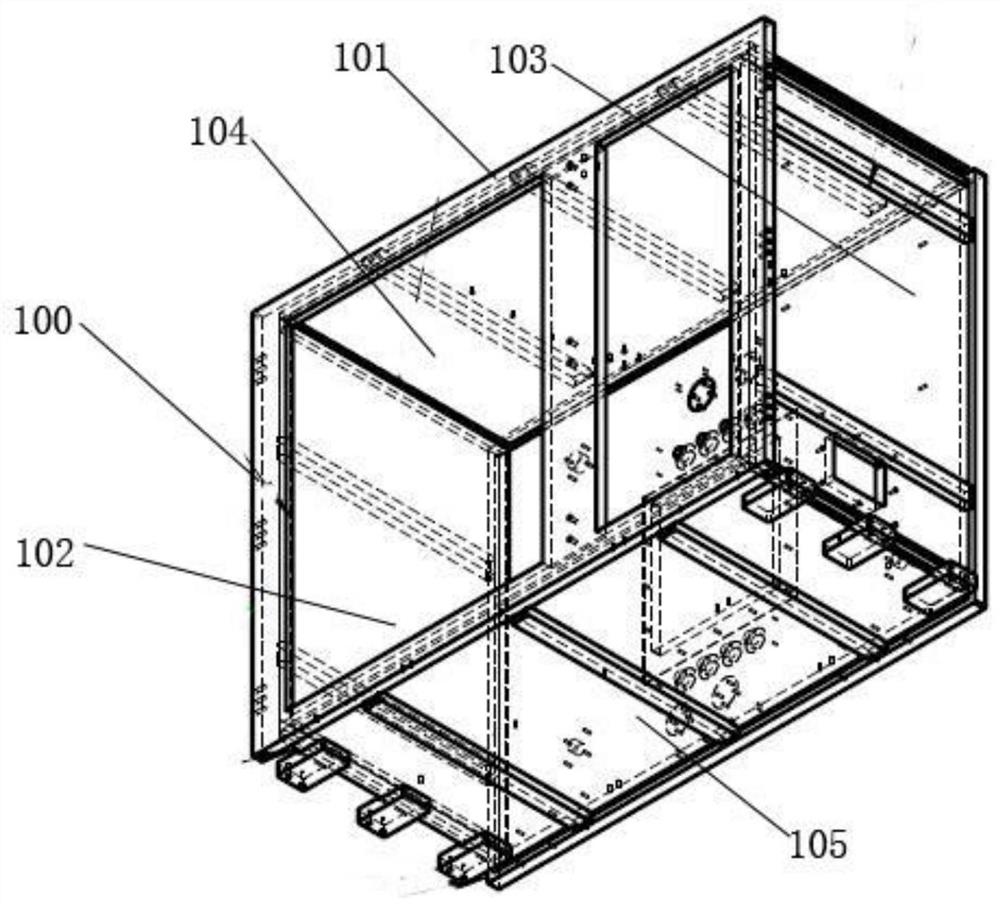

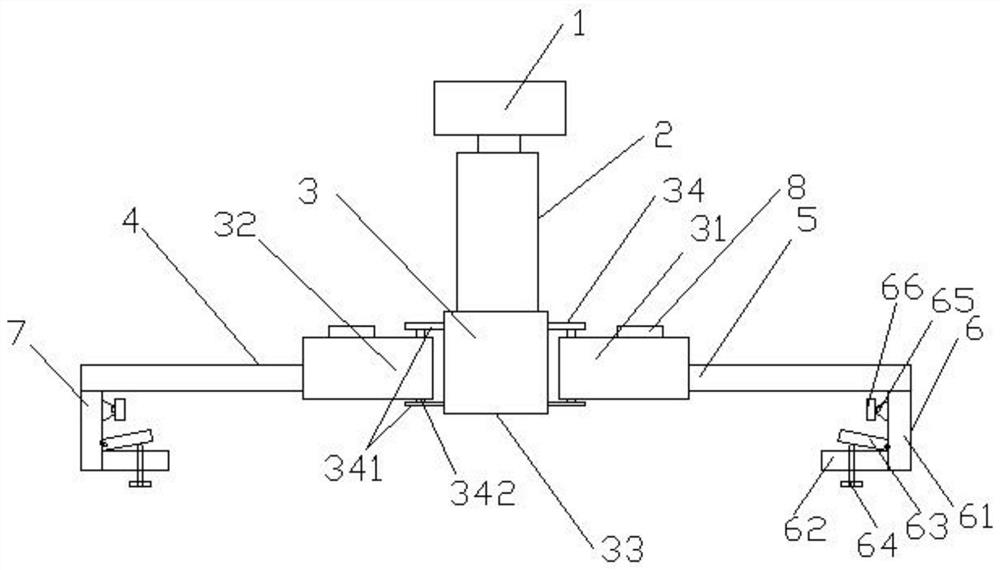

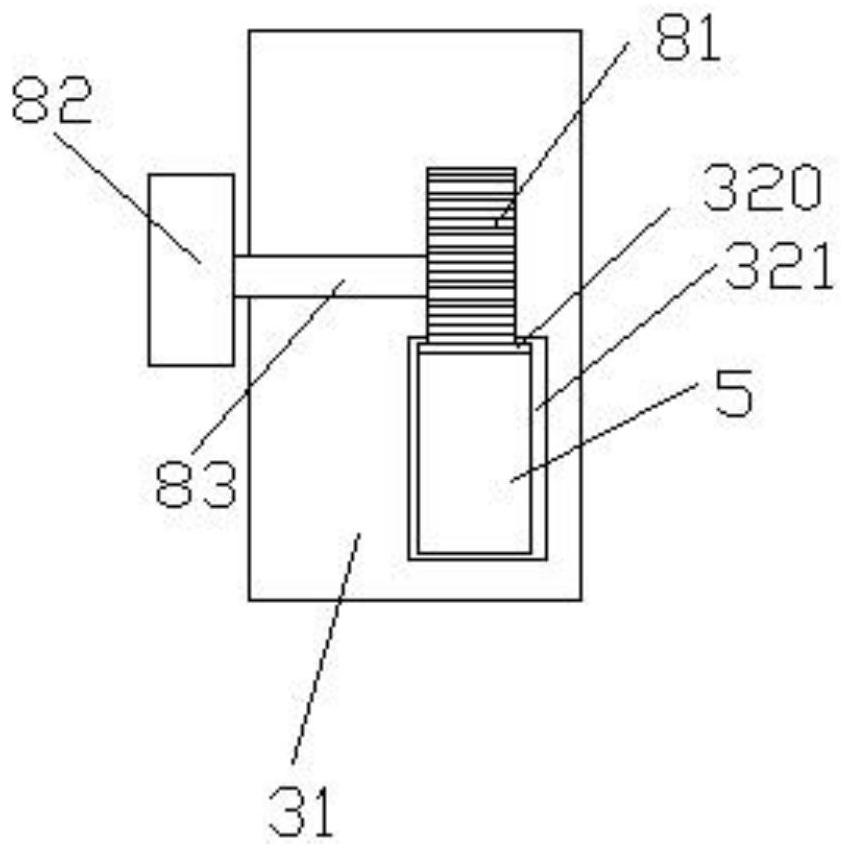

[0032] see Figure 1 to Figure 4 , this embodiment shows a modular combined multi-directional synchronous fixed processing structure, including a fixed position conveniently adjustable processing structure, a fixed position conveniently adjustable processing structure includes a fixed setting block 3, and both sides of the fixed setting block 3 are provided with rotating The connecting assembly 34, the rotating connecting assembly 34 that is arranged on both sides of the fixed setting block 3 are respectively provided with a rotating plate A32 and a rotating plate B31, and the rotating plate A32 and the rotating plate B31 are all provided with an adjustment slide chamber 321, and the rotating plate A32 and the rotating The adjustment sliding cavity 321 of the plate B31 is respectively connected to the clamping setting plate A4 and the clamping setting plate B5 through the telescopic adjustment structure 8, and the ends of the clamping setting plate A4 and the clamping setting p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap