Method for separating and purifying cannabinol from industrial hemp

A technology for separation and purification of industrial hemp, applied in the field of chemistry, to achieve the effect of solving the problem of separation and purification, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

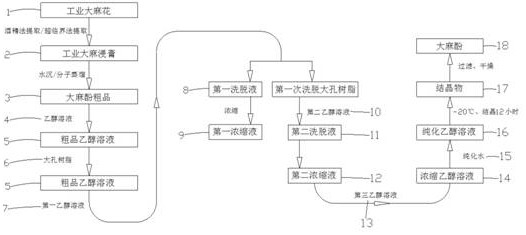

[0031] A method for separating and purifying cannabinol from industrial hemp, the steps are as follows:

[0032] A. Prepare industrial hemp flower 1, extract industrial hemp extract 2 by alcohol method, use water sinking method for industrial hemp extract 2 to obtain cannabinol crude product 3 with a content of 15%-35%, weigh 100g of cannabinol crude product 3;

[0033] B. Add ethanol solution 4 to the crude cannabinol 3 and stir to obtain the crude ethanol solution 5. The ratio of the crude cannabinol 3 to the ethanol solution 4 is 1g: 5-10ml, so according to the quality of the crude cannabinol 3, Configure 500ml of ethanol solution 4;

[0034] C, the crude ethanol solution 5 is evenly added to the column of the activated macroporous resin 6, and the sample load is 1%; the model of the macroporous resin 6 is D201;

[0035] D, macroporous resin 6 is carried out normal pressure elution with the first ethanol solution 7 of 40% to obtain the first eluent 8 and elute macroporous...

Embodiment 2

[0040] A method for separating and purifying cannabinol from industrial hemp, the steps are as follows:

[0041] A. Prepare industrial hemp flower 1, use supercritical method to extract industrial hemp extract 2, obtain the crude product 3 of cannabinol with a content of 15%-35% for the method of molecular distillation of the industrial hemp extract 2, and weigh 150g of crude cannabinol 3;

[0042] B. Add ethanol solution 4 to the crude cannabinol 3 and stir to obtain the crude ethanol solution 5. The ratio of the crude cannabinol 3 to the ethanol solution 4 is 1g: 5-10ml, so according to the quality of the crude cannabinol 3, Configure 900ml of ethanol solution 4 to get final product;

[0043] C, the crude ethanol solution 5 is evenly added to the column of the activated macroporous resin 6, and the sample load is 3%; the model of the macroporous resin 6 is D201;

[0044] D, macroporous resin 6 is carried out normal pressure elution with the first ethanol solution 7 of 55% ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap