A kind of hydrogen sulfide inhibitor for drilling fluid and preparation method thereof

A hydrogen sulfide and inhibitor technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems that threaten the personal safety of on-site operators and affect the smooth progress of drilling work, so as to avoid poisoning accidents and increase drilling fluid The effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

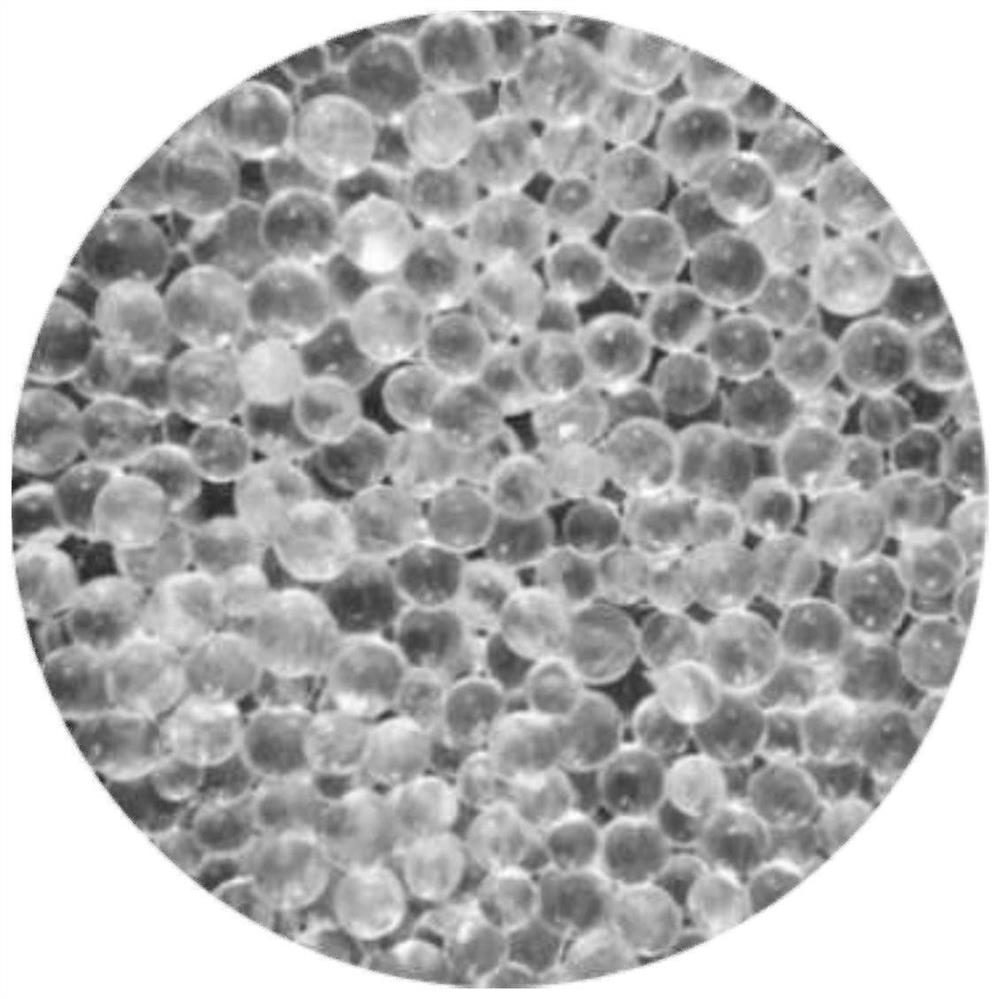

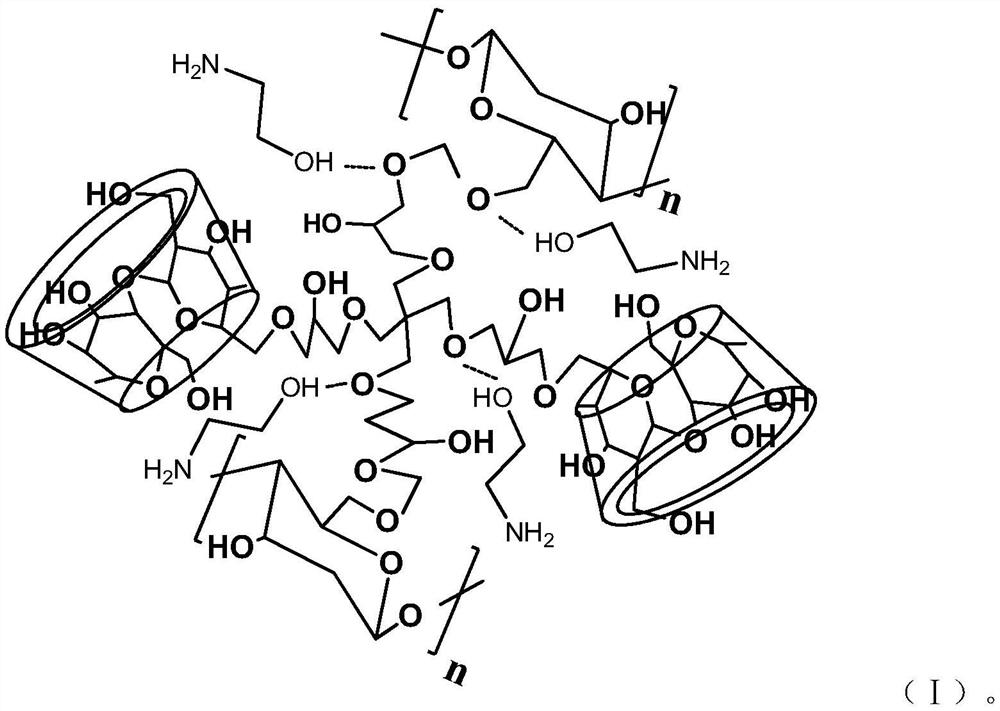

[0022] Add 3 g of sodium hydroxide to 50 mL of ethanolamine solution with a mass fraction of 40%, stir at room temperature for 5 min, add 1.78 g of carboxymethyl cellulose and 1.55 g of β-cyclodextrin, continue stirring for 5 min, add 3.15 g of pentaerythritol oxypropane ether, and increase the speed to 800rpm, after 2min, add 100mL of liquid paraffin, stir at 40°C for 24h, and filter to obtain a wet bulb (see attached figure 1 ), vacuum-dried at 35°C for 24 hours to obtain 4.21 g of ethanolamine-doped cellulose / cyclodextrin microspheres with a particle size of 200 μm (see attached figure 2 ).

Embodiment 2

[0024] As in Example 1, the stirring speed was increased to 1200 rpm to obtain 3.87 g of 100 μm ethanolamine-doped cellulose / cyclodextrin microspheres.

Embodiment 3

[0026] As in Example 2, 150 mL of liquid paraffin was added to obtain 3.02 g of 80 μm ethanolamine-doped cellulose / cyclodextrin microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com