Corrosion-resistant pump of chemical high-temperature pump

A technology of corrosion-resistant pump and high-temperature pump, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of high cost of pump body, high corrosion resistance and high abrasion resistance of overcurrent parts, etc., to achieve acid resistance. Strong alkali corrosive ability, wide application range, and the effect of reducing maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

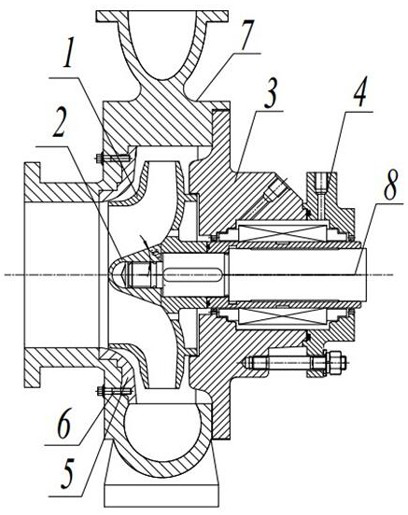

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

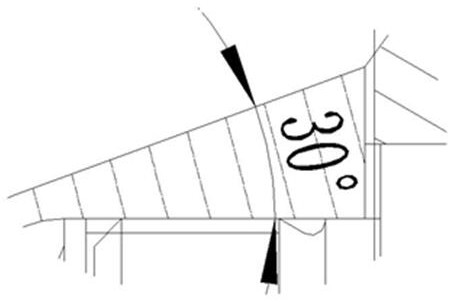

[0029] A chemical high temperature pump corrosion resistant pump, comprising a pump body 7 and an impeller 1 arranged in the pump body 7. A through pump body inlet and a pump body outlet are provided on the pump body 7, and the impeller 1 is located at the pump body inlet and the pump body outlet The pump body 7 between the pump body 7 is provided with a pump cover 3, a mechanical seal gland 4, and a pump shaft 8 is provided in the pump body 7. The impeller 1 is axially positioned by the impeller nut 2 and the pump cover 3. The shaft 8 transmits power; the impeller nut 2 is screwed and connected to the pump shaft 8, and the impeller 1 is screwed and fixed to the pump shaft 8 through the impeller nut 2; the pump cover 3 and the mechanical seal gland 4 are connected by bolts; Both ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap