A cooler inner core cleaner

A cleaner and cooler technology, which is applied in the field of air compressor aftercooler and intercooler inner core cleaning, can solve the problems of low work efficiency and increase the workload of staff, and achieve safe and convenient use, high stability, Scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

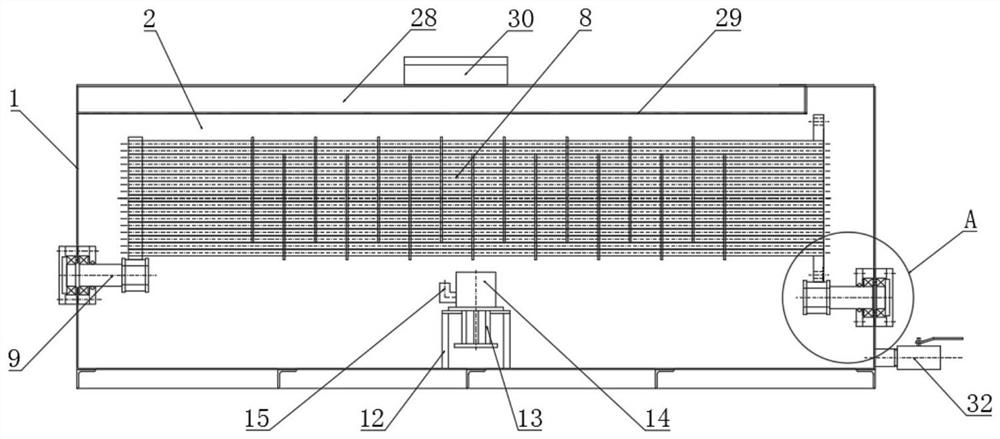

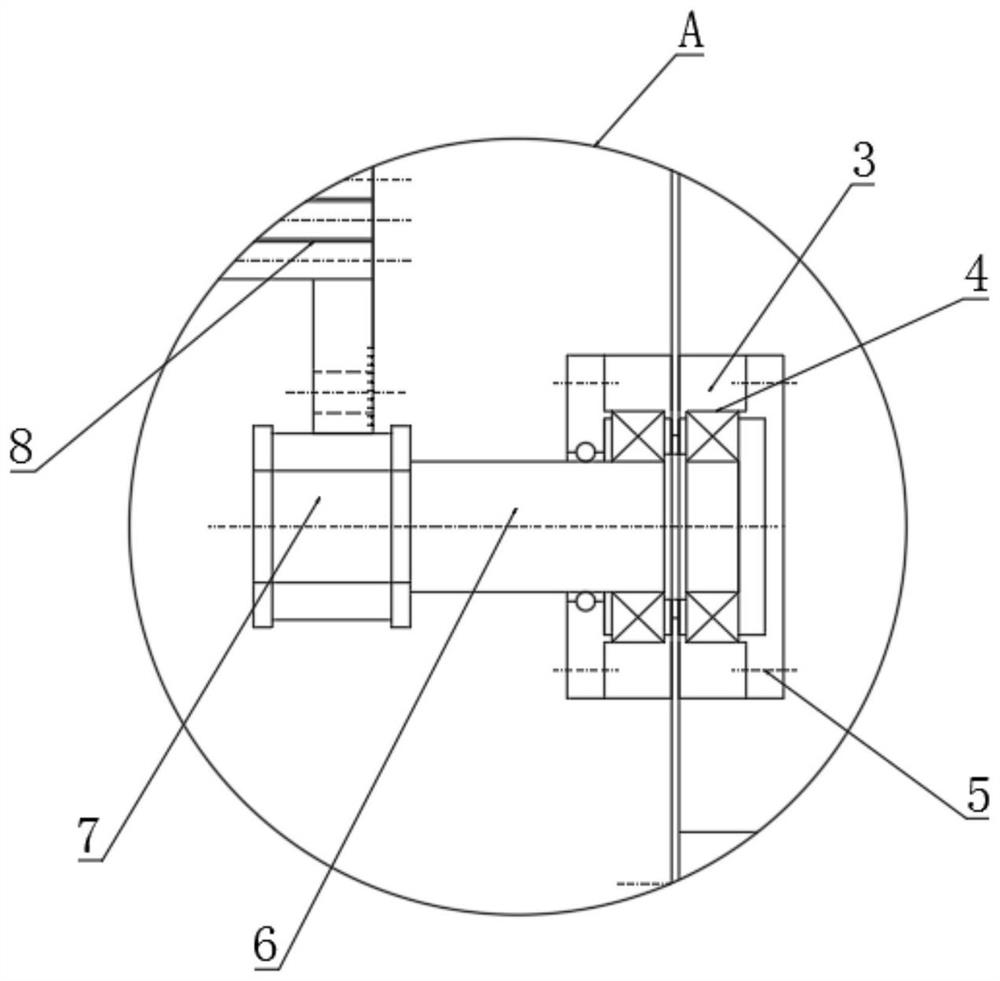

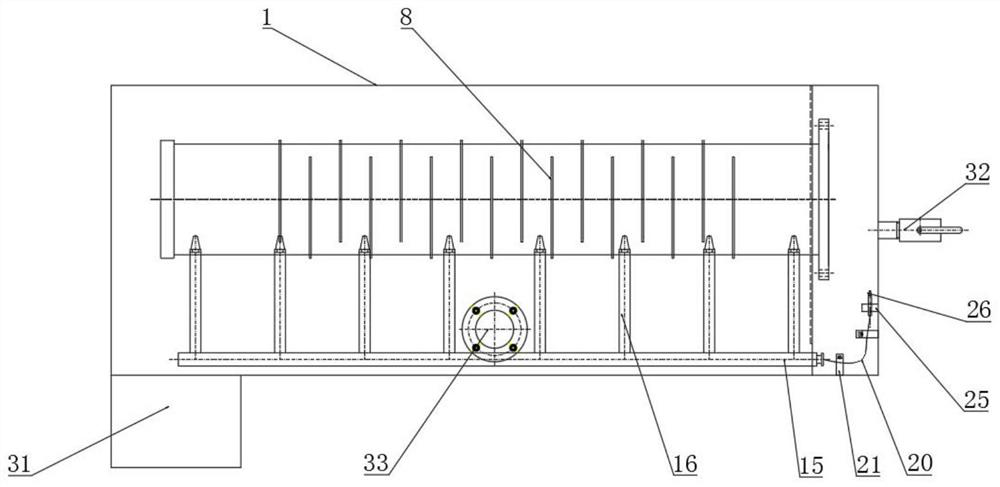

[0031] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a cooler inner core cleaner, including a washer body 1, a power distribution box 31 is installed at the top of one end of the washer body 1, and a fixed connection is made at the bottom of the washer body 1 There is a drain valve 32, a cleaning chamber 2 is provided inside the washer body 1, and bearing seats 3 are fixedly connected to both ends of the washer body 1, which is convenient for sealing the connection between the bearing seat 3 and the washer body 1, and the two bearing seats 3. One end runs through the washer body 1, and both ends are fixedly connected with the inner wall of the cleaning chamber 2. A sealing strip is pasted on the connection between the bearing seat 3 and the washer body 1. The inner wall of the bearing seat 3 is provided with a mounting groove 4, which is snapped inside There is a bearing protection cap 5;

[0032] A first driven shaft 6 is rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com