Highway tunnel jet fan supporting structure bearing capacity detection device and detection method

A technology of jet fan and supporting structure, which is applied in the testing of machine/structural components, measuring devices, testing of mechanical components, etc., can solve the problems of long testing and construction time, and difficulty in meeting the requirements of the project construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following is attached Figure 1-6 The application is described in further detail.

[0051]This application discloses a bearing capacity detection device for a jet fan support structure in a highway tunnel:

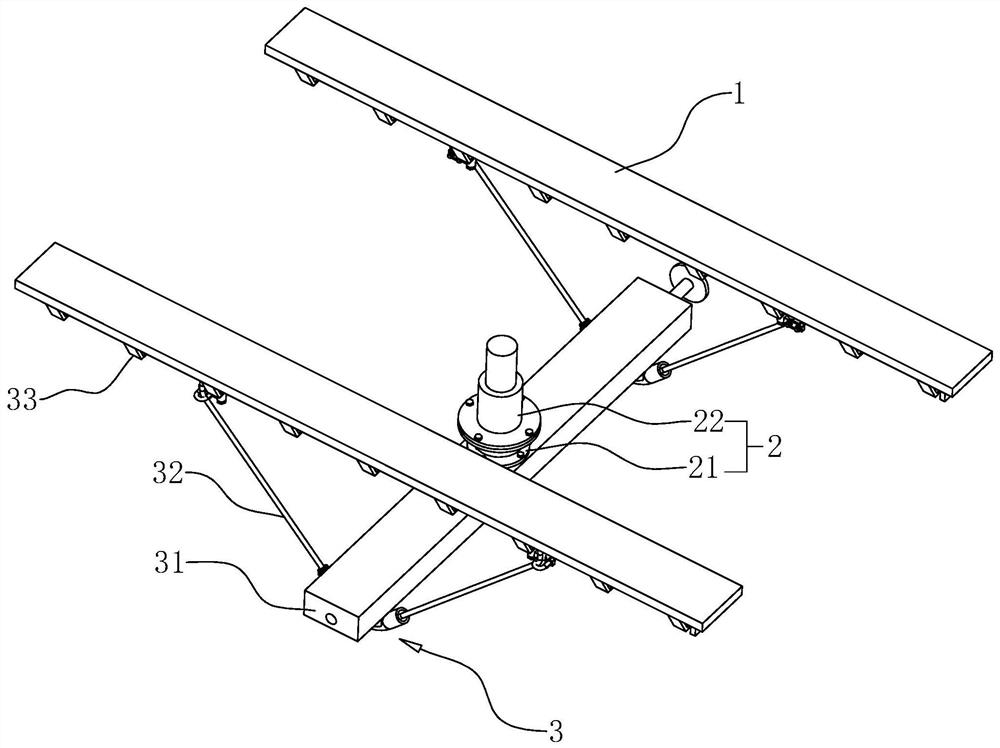

[0052] refer to figure 1 , the rapid detection device for the bearing capacity of the support structure of the jet fan in the highway tunnel includes a reaction force assembly 3, the reaction force assembly 3 includes a beam 31, the two ends of the beam 31 are respectively threaded with steel wire ropes 32, and the two ends of the steel wire rope 32 are respectively connected to the pre-embedded steel plate 1 , The upper surface of the beam 31 is provided with a pressurizing assembly 2, and the pressurizing assembly 2 abuts against the tunnel roof wall.

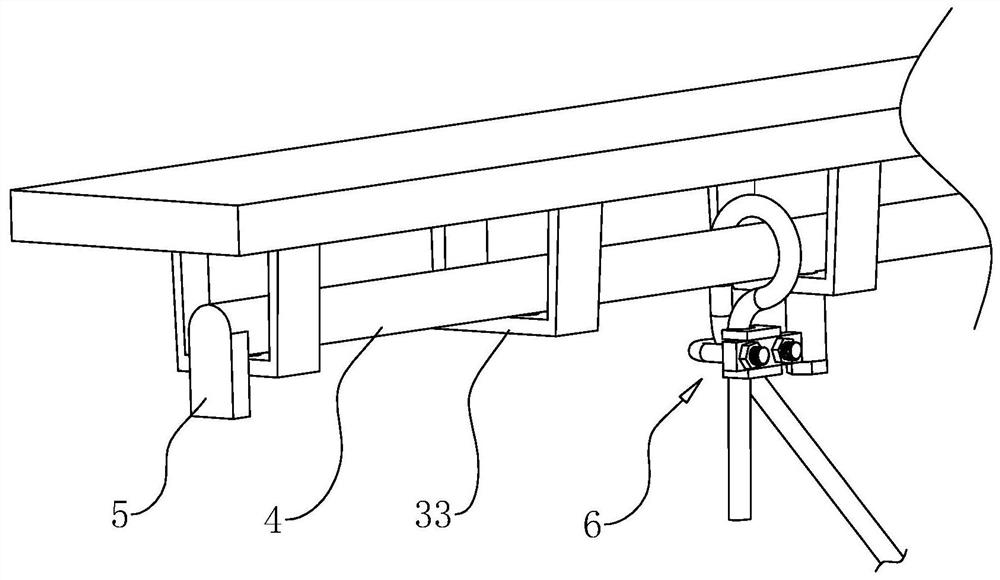

[0053] refer to figure 2 The lower surface of the pre-embedded steel plate 1 is welded and fixed with connectors 33. There are multiple groups of connectors 33 arranged along the length direction of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com