Permanent magnet electric roller explosion suppression performance safety protection device, self-checking method thereof and explosion suppression type permanent magnet electric roller

A technology of safety protection device and electric drum, which is applied in the direction of automatic disconnection emergency protection device, emergency protection circuit device, electromechanical device, etc., can solve the hidden danger of permanent magnet electric drum and other problems, and achieve the effect of expanding the use power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

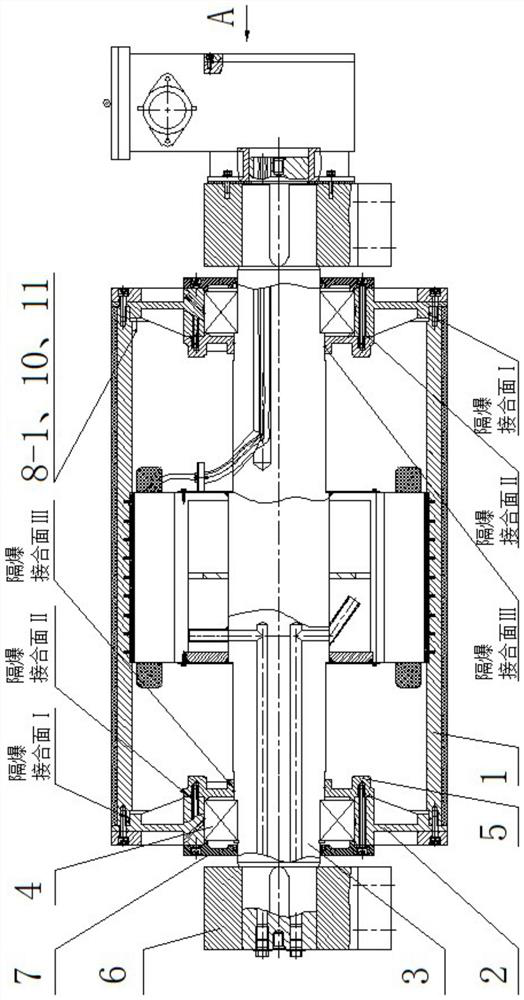

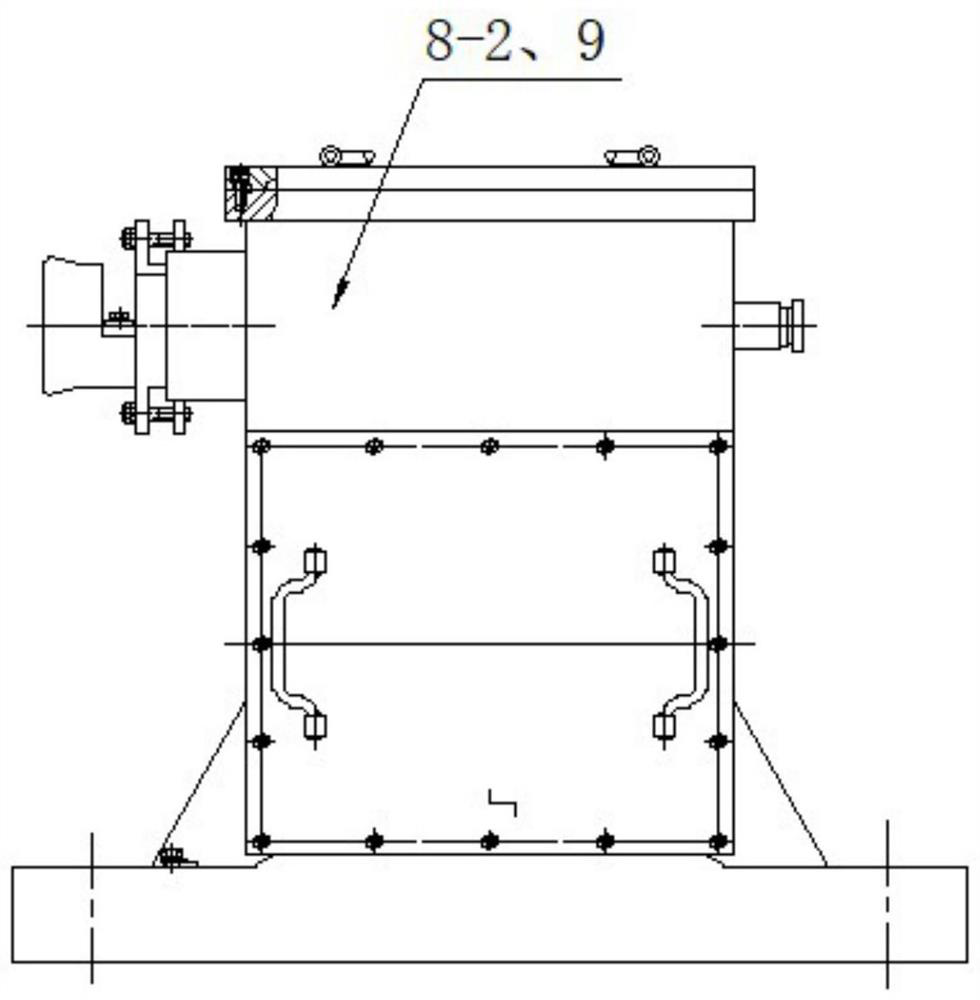

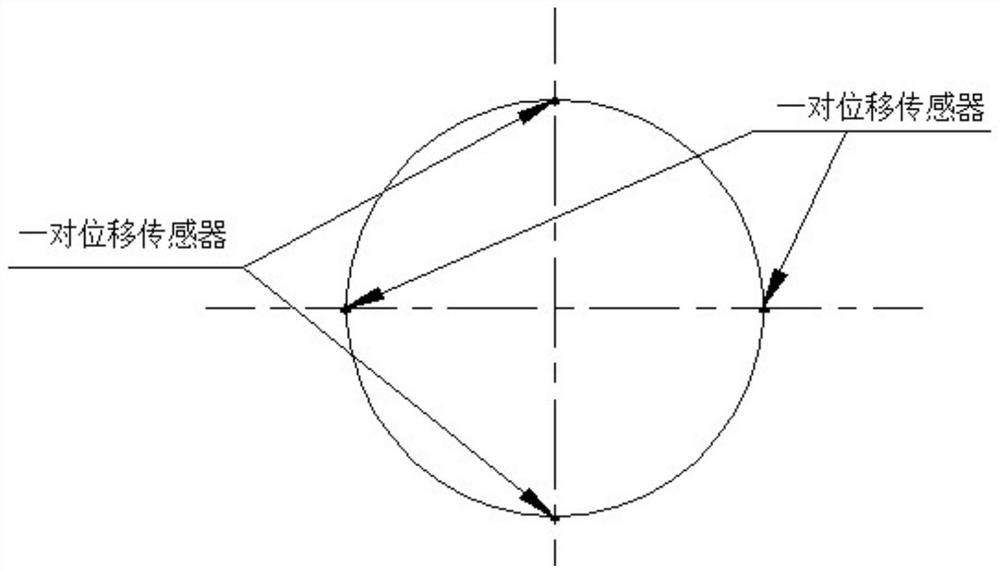

[0021] The invention discloses a safety protection device for the explosion-proof performance of a permanent magnet electric drum, such as Figure 1-4 As shown, it includes a displacement sensor, a sensor mounting bracket 11, a signal transmission device, and an intelligent fault diagnosis system 9. At least one set of the displacement sensor is installed at each flameproof joint surface of the permanent magnet electric drum, and the installation method is directly installed The relevant parts of the permanent magnet electric drum or the sensor mounting bracket 11 are installed to the relevant parts of the permanent magnet electric drum. The displacement sensor is used to measure the absolute value and change value of the flameproof gap at the corresponding flameproof joint surface in real time. The signal output ends of all displacement sensors are connected to the intelligent fault diagnosis system through the signal transmission device, and the measurement result signals of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com