Method for producing a bellows

A bellows, thermoplastic elastomer technology, applied in the field of bellows, can solve the problem of not being able to manufacture bellows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] First, a typical arched bellows with external reinforcement was prepared from a mixture of thermoplastic block copolymer and rigid polybutylene terephthalate, soft polytetrahydrofuryl terephthalate, One end of the bellows is fixed on the joint housing, and the other end is fixed on the shaft.

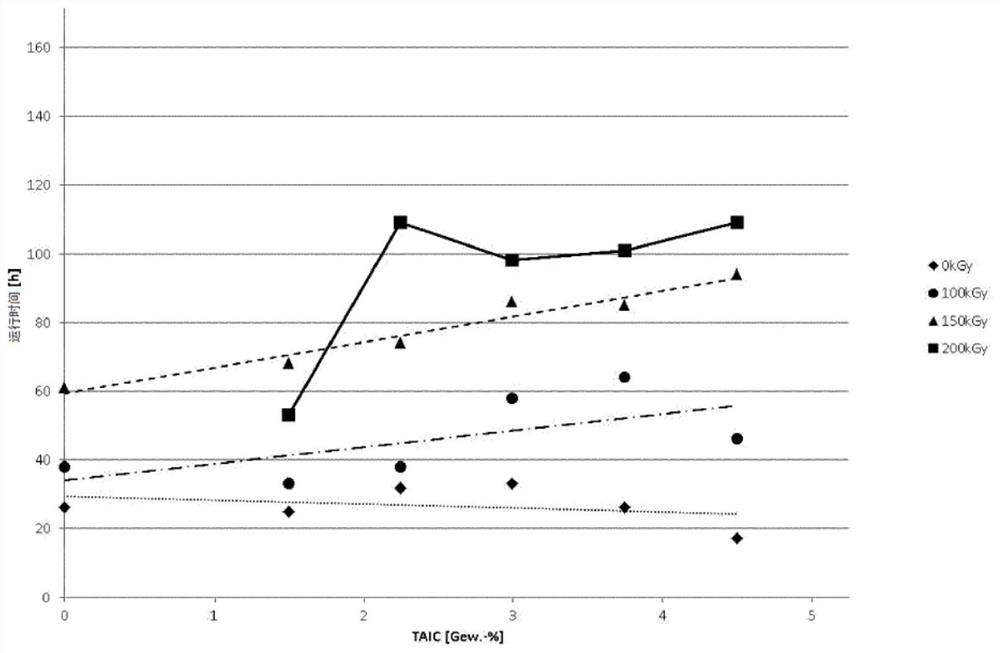

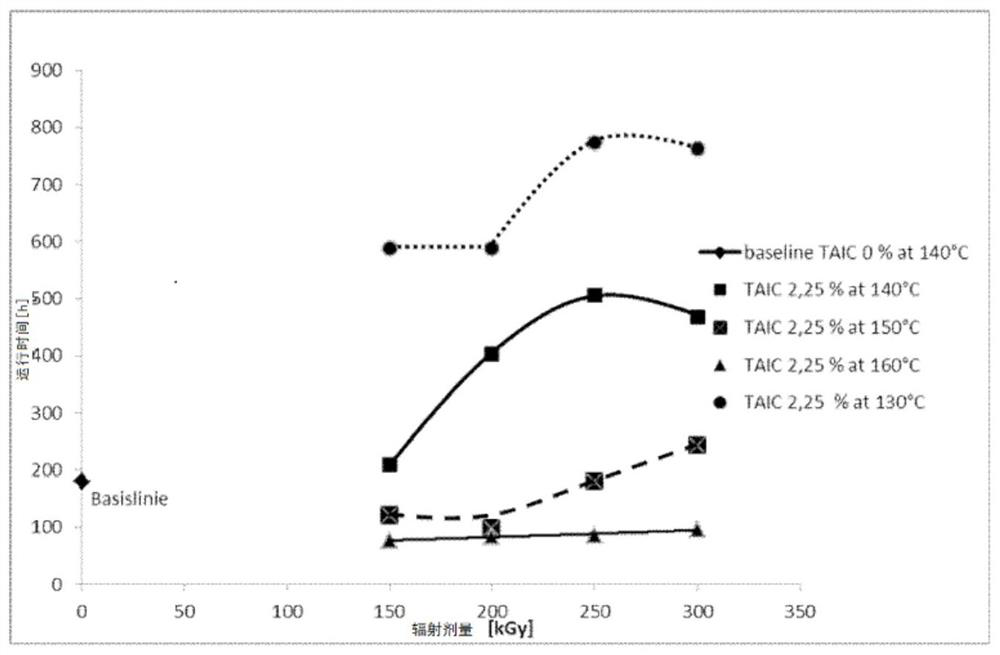

[0028] First, a premix was prepared from 15% by weight of triallyl isocyanurate and 85% of thermoplastic block-copolyester, relative to the total amount of the premix. In the mixture thus obtained, the triallyl isocyanurate content was respectively 0% by weight, 1.5%, 2.25%, 3%, 3.75% and 4.5% ( weight), and the bellows are produced by an injection molding process, for example using a screw extruder. The nozzle discharge temperature of the screw extruder was 245°C.

[0029] Electron irradiation is then carried out with an electron beam unit with eight electron beams directed uniformly from above over the entire outer surface of the arched bellows to ensure a uniform energy inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com