High-sunlight-reflectivity ceramic glaze, building energy-saving porcelain glazed tile and preparation method thereof

A ceramic glaze and reflectivity technology, applied in the field of building materials, can solve the problems of ineffective reflection of sunlight, low solar reflection index, high radiation absorption, etc., and achieve large-scale industrial production, low brick surface temperature, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

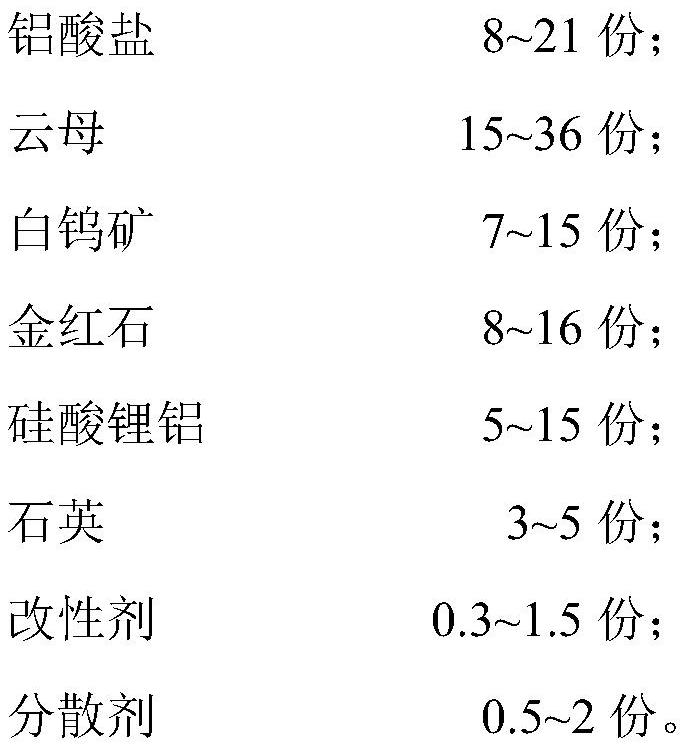

[0029] A high solar reflectance ceramic glaze, which comprises the following raw material components by weight:

[0030]

[0031]

[0032] A building energy-saving porcelain glazed tile using the high solar reflectance ceramic glaze, which includes a body layer and a glaze layer arranged on the surface of the body layer, the building energy-saving porcelain glazed tile The preparation method is as follows:

[0033] 1) Mix the raw material components of the high solar reflectance ceramic glaze in parts by weight, and use wet ball milling to mix and ball mill until the fineness is 0.3% of the 325 mesh sieve to obtain the high solar reflectance ceramic glaze of Example 1;

[0034] 2) Spread the high solar reflectance ceramic glaze obtained in step 1) on the green body layer of ordinary porcelain tiles to form a surface glaze layer, which is then dried and fired at high temperature in a kiln. The firing temperature is controlled at 1200°C to obtain Embodiment 1 finished pro...

Embodiment 2

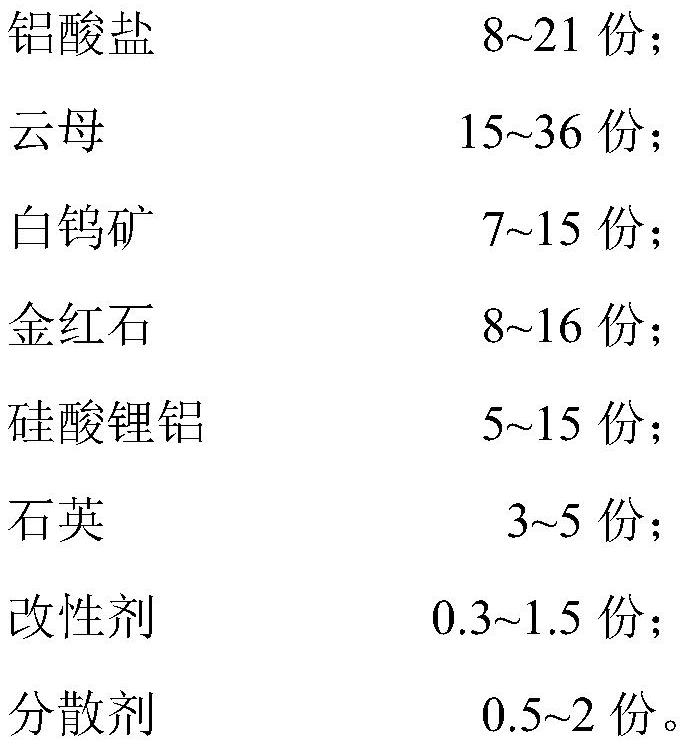

[0036] A high solar reflectance ceramic glaze, which comprises the following raw material components by weight:

[0037]

[0038] A building energy-saving porcelain glazed tile using the high solar reflectance ceramic glaze, which includes a body layer and a glaze layer arranged on the surface of the body layer, the building energy-saving porcelain glazed tile The preparation method is as follows:

[0039] 1) Mix the raw material components of the high solar reflectance ceramic glaze in parts by weight, and use wet ball milling to mix and ball mill until the fineness is 0.6% of the 325 mesh sieve to obtain the high solar reflectance ceramic glaze of Example 2;

[0040] 2) Spread the high solar reflectance ceramic glaze obtained in step 1) on the green body layer of ordinary porcelain tiles to form a surface glaze layer, which is then dried and fired at high temperature in a kiln. The firing temperature is controlled at 1150°C to obtain Embodiment 2 finished product.

Embodiment 3

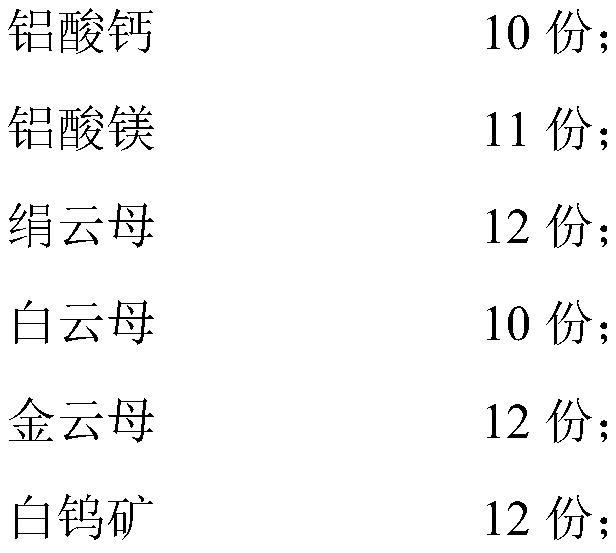

[0042] A high solar reflectance ceramic glaze, which comprises the following raw material components by weight:

[0043]

[0044] A building energy-saving porcelain glazed tile using the high solar reflectance ceramic glaze, which includes a body layer and a glaze layer arranged on the surface of the body layer, the building energy-saving porcelain glazed tile The preparation method is as follows:

[0045] 1) Mix the raw material components of the high solar reflectance ceramic glaze in parts by weight, and use wet ball milling to mix and ball mill until the fineness is 0.5% of the 325-mesh sieve to obtain the high solar reflectance ceramic glaze of Example 3;

[0046] 2) Spread the high solar reflectance ceramic glaze obtained in step 1) on the green body layer of ordinary porcelain tiles to form a surface glaze layer, which is then dried and fired at high temperature in a kiln. The firing temperature is controlled at 1180°C to obtain Embodiment 3 finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com