Rotary spraying type roadway dust flushing and water falling device

A technology of spraying device and rotating device, which is applied in the direction of safety device, dust prevention, mining equipment, etc. It can solve the problems of insufficient dust removal and spraying, labor and water resources consumption, etc., and achieve low installation cost, high efficiency and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

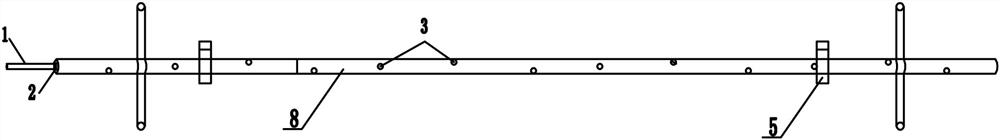

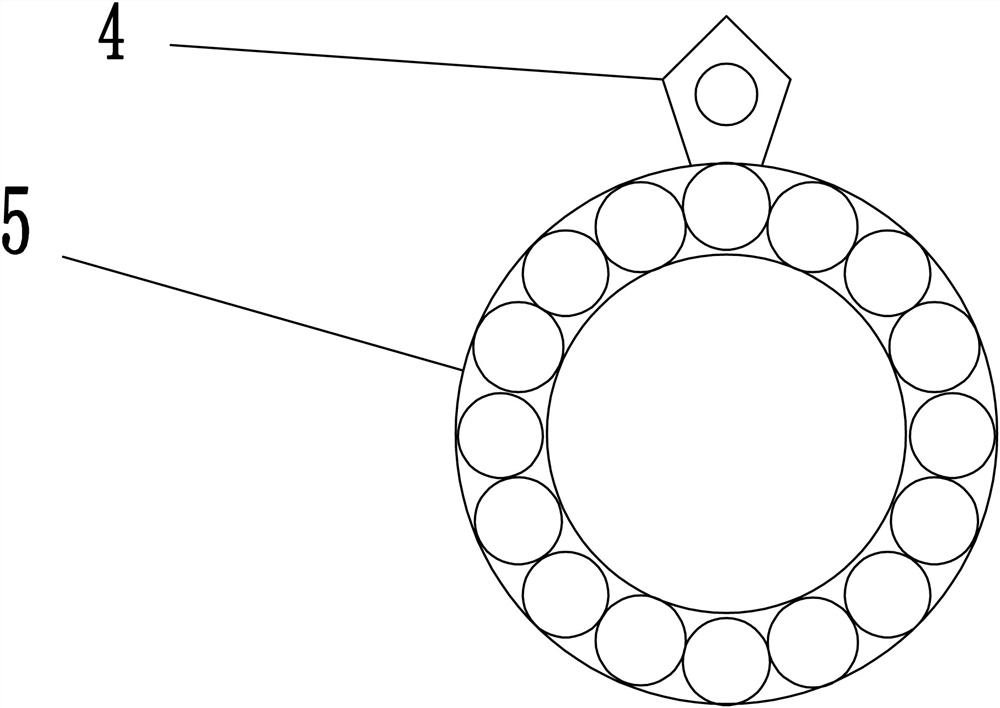

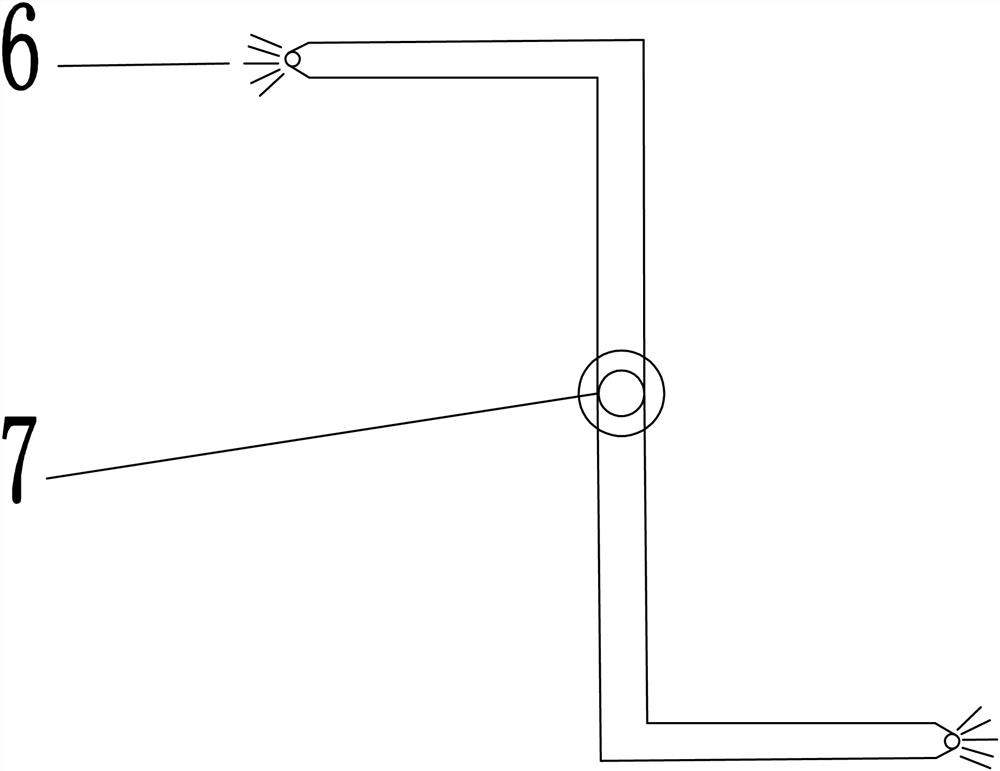

[0019] Attached below in conjunction with the instructions Figure 1~3 The present invention is further explained: rotary jetting type roadway dust washing and precipitation device

[0020] It is composed of a rotating spraying device, a spraying straight rod and a rotating water supply, and it is hung and fixed in the required dust removal and spraying area. Connect the pressurized water source with the rotating water supply, and supply water to a straight steel pipe for up to 50 meters. The push rod pushes the steel pipe to rotate through the hydraulic ejection force. The steel pipe is punched to form a water column to wash the roadway and the surrounding environment. Spraying to complete dust washing or precipitation in the roadway. The rotary spraying device is driven by the water supply pressure above 0.5MPa.

[0021] The spray head is installed vertically on the spray rod (50cm) of the rotating device, and is connected to the spraying straight pipe by vertical welding. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com