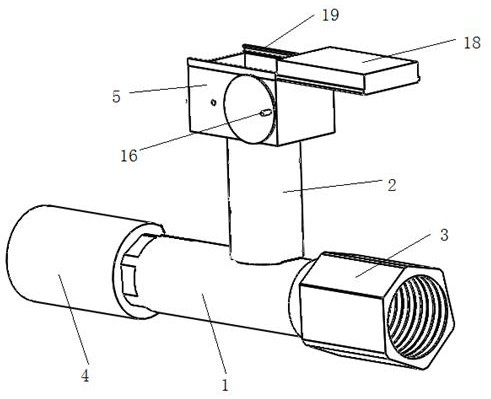

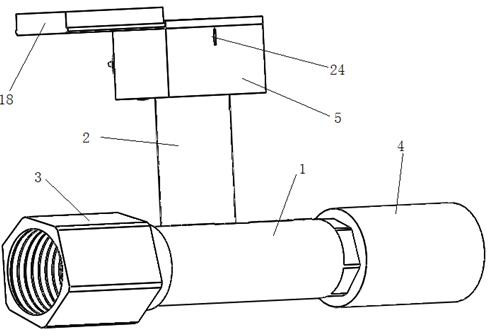

Pipe network hydraulic detection device

A hydraulic detection and pipe network technology, which is applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as hand shaking, affecting measurement accuracy, and inconsistencies between parameters and actual values. Reduce the effect of error and fluctuation of external factors, and reduce the fluctuation of standard instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

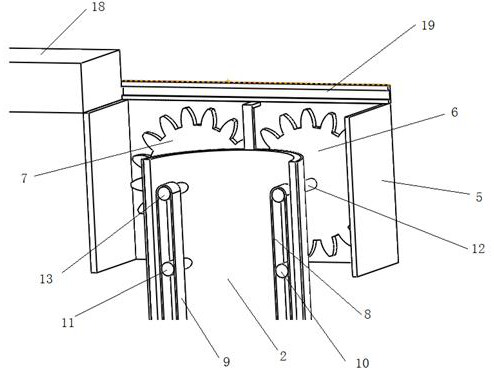

[0027]This embodiment is a further improvement of Embodiment 1. The main improvement is that in Embodiment 1, when the standard is transported by the transport mechanism, when will the probe at the bottom of the standard reach the transport tube 2 and the main tube 1 The junction of the connection cannot be accurately judged, and the detection probe protruding into the main pipe 1 too deep or too shallow will affect the accuracy of the measurement results. In this embodiment, however, it can be more accurately judged when the detection probe arrives at the joint between the delivery tube 2 and the main tube 1 .

[0028] Specifically, in the pipe network hydraulic pressure detection device in this embodiment, such as Figures 5 to 7 A positioning shaft 20 with a length shorter than the inner diameter of the delivery pipe 2 is also fixed laterally at the connection between the delivery pipe 2 and the main pipe 1, and a contact rod 21 with a length smaller than the inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com