Method and device for analyzing bending deformation of functionally gradient multilayer magnetoelectric elastic nano-plate

A functional gradient and bending deformation technology, applied in the field of bending deformation analysis of functionally graded multilayer magneto-elastic nanoplates, and bending deformation analysis devices of functionally graded multilayered magneto-elastic nanoplates, can solve problems such as low precision and achieve The effect of high solution accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

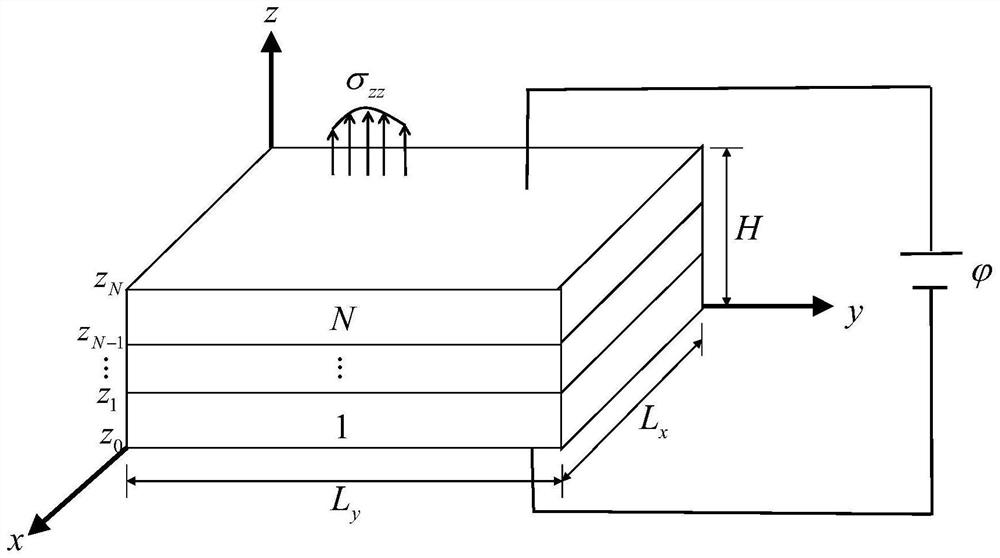

[0055] see figure 1 , the present embodiment provides a bending deformation analysis method of a functionally graded multilayer magneto-electroelastic nanoplate, and the analytical method is used for the mechanical load and electric load on the surface of a functionally graded multilayer nanoplate composed of a magneto-electric-elastic material. The static bending deformation under the action is solved. In this embodiment, it is assumed that the functionally graded material is distributed exponentially along the thickness direction, and the interface displacement and stress of each layer are continuous, and the solution result of the multilayer board is obtained by using the transfer matrix method. Among them, the bending deformation analysis method includes the following four main steps.

[0056] (1) First establish the three-dimensional coordinate system of the functionally graded multilayer nanoplate, and then apply electroelastic loads on both ends of the functionally gra...

Embodiment 2

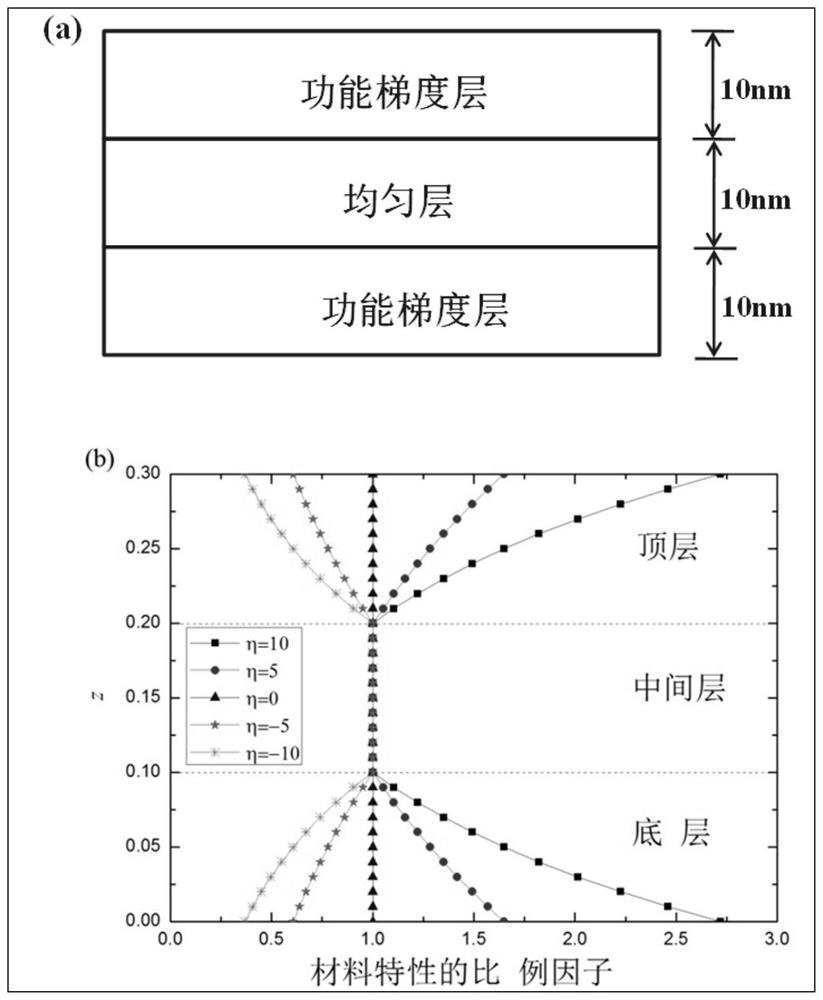

[0134] This embodiment provides a method for analyzing the bending deformation of a functionally graded multilayer magneto-electroelastic nanoplate, and this method adds a numerical example on the basis of Embodiment 1. In the numerical analysis, a BaTiO 3 (abbreviated as B) and Al-Ni-Co (abbreviated as F) composed of rectangular layered functionally graded sandwich nanoplates. z-independent material properties [36] They are listed in Table 1-2 respectively. Sandwich panels with two ply sequences namely B / F / B and F / B / F were investigated. The middle layer of the sandwich panel is uniform, and the top and bottom layers are functionally graded materials with symmetrical exponential changes, such as figure 2 shown. figure 2 η in represents the exponential factor of the top layer, and five different exponential factors, ie η=-10,-5,0,5,10, were studied.

[0135] The length and width of the nanoplate are Lx=Ly=100nm and height H=30nm. The material length scale parameter l is...

Embodiment 3

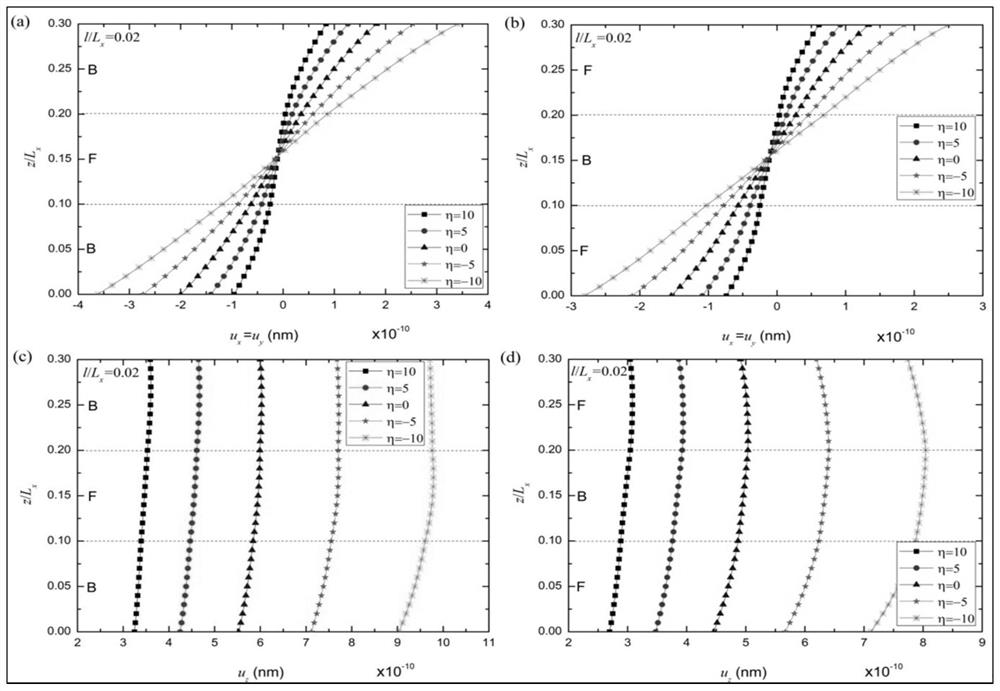

[0143] This embodiment provides a bending deformation analysis method of a functionally graded multilayer magnetoelectric elastic nanoplate, which is similar to that of Embodiment 2, the difference is that this embodiment studies the effect of non-local parameters on two functional gradients under the action of a force load. Effects of generalized displacement and generalized stress in sandwich nanoplates.

[0144] see Figure 9-14 , showing the displacement u of a functionally graded magnetoelectric sandwich panel under force loading for two different stacking orders x = u y and u z , potential Magnetic potential ψ, stress σ xz ,σ zz ,σ xx ,σ xy , Magnetic induction B x ,B z and electric displacement D x ,D z Variation law along the thickness direction with the non-local parameter l. From Figure 9 It can be found that when the exponent factor η=5 is taken, the displacement u x , u z The changing trends in the two kinds of functionally graded sandwich nanoshee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com