Manual opening and closing device of ring main unit

A technology of opening and closing, ring main unit, applied in the direction of high-voltage air circuit breakers, electrical components, electric switches, etc., can solve the problems of slow opening speed and long transmission path, and achieve the effect of improving opening speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Below in conjunction with accompanying drawing this embodiment is described in detail:

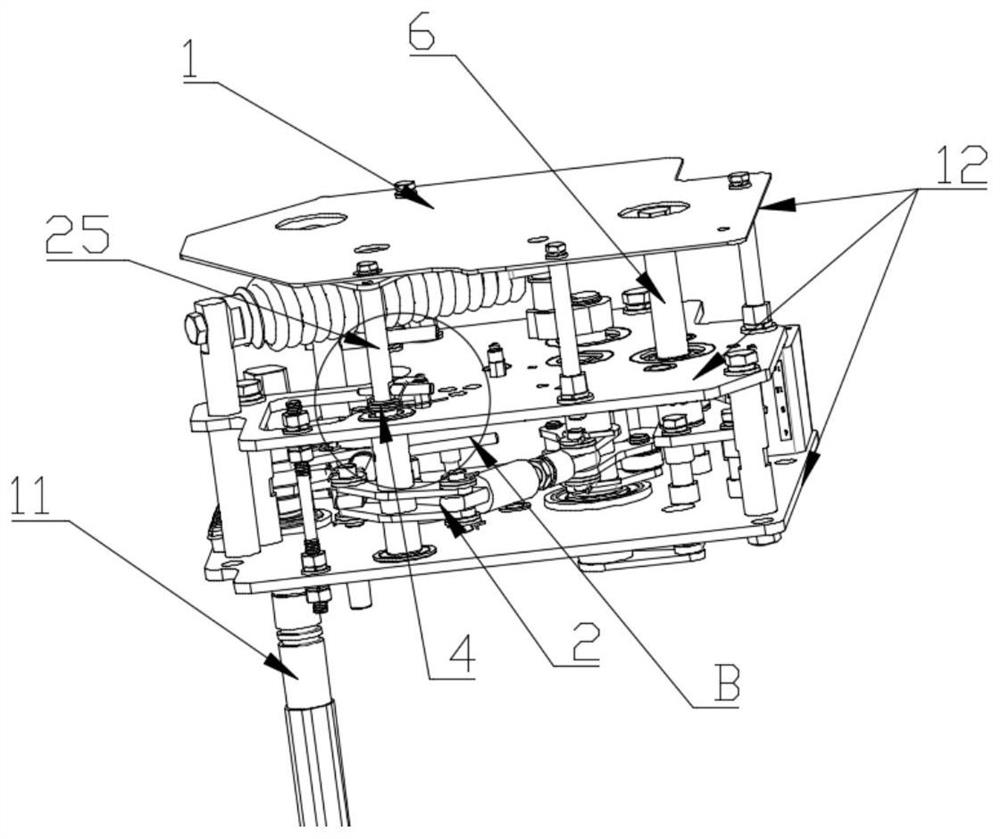

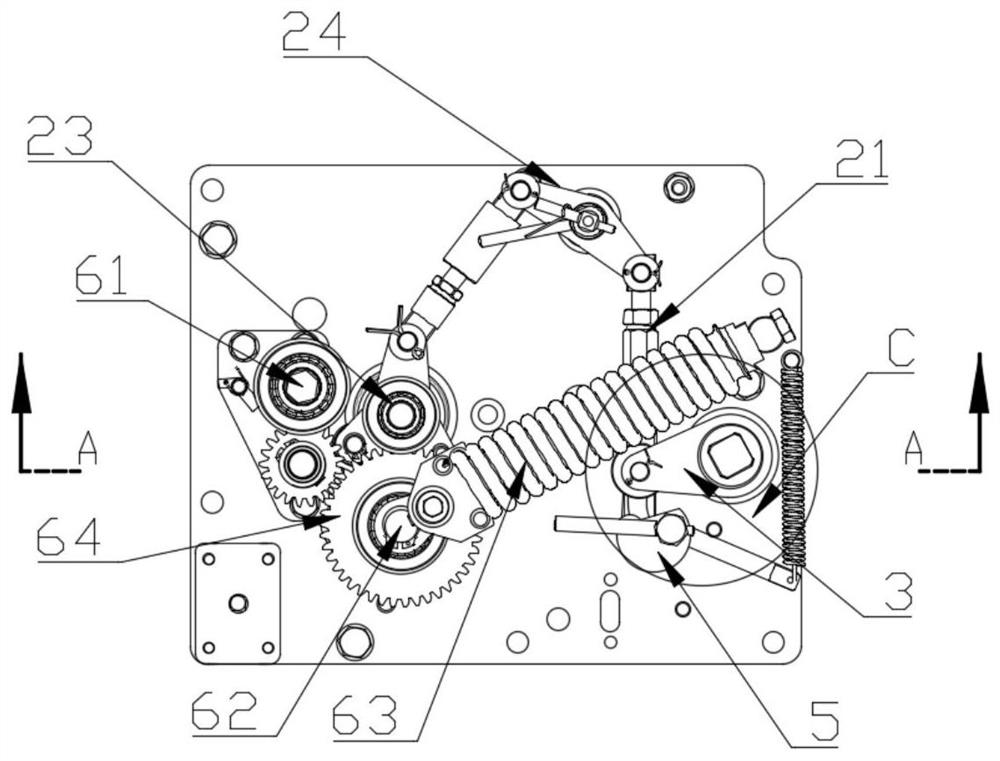

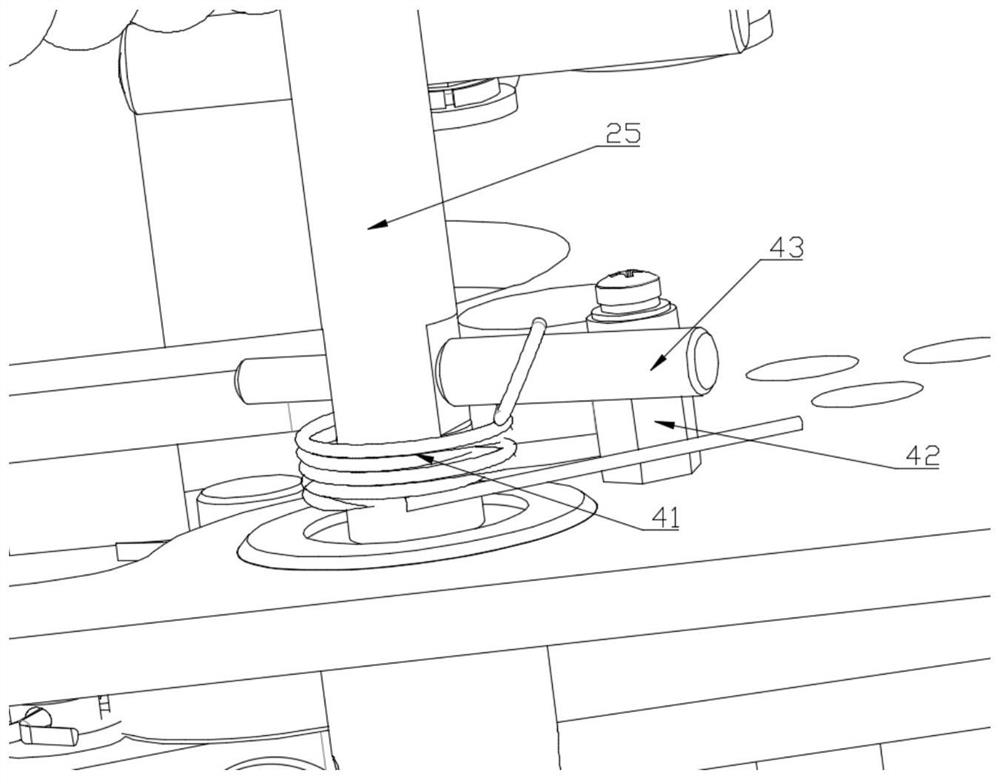

[0044] The present invention provides such as Figure 1-6 A ring network cabinet manual opening and closing device is shown, which is used to drive the opening and closing operation of the circuit breaker in the ring network cabinet body 1, including the permanent magnet operating structure installed in the cabinet body 1 and the circuit breaker The connected main shaft 11, and the manual operating mechanism installed on one side of the cabinet body 1 and connected to the main shaft 11, the permanent magnet operating mechanism drives the main shaft 11 to rotate and drives the electric opening and closing of the circuit breaker. The main shaft 11 can be forwardly rotated to the closing position or reversely rotated to the opening position under the drive of the manual operation mechanism. When the main shaft 11 is in the opening position, the opening and power failure are realized, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com