Array washing waste gas purification device

An exhaust gas purification device and array technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve the problem of single filter structure, insufficient filtering effect of dust and water-soluble acid and alkali waste gas chemicals, and filtering effect. issues to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

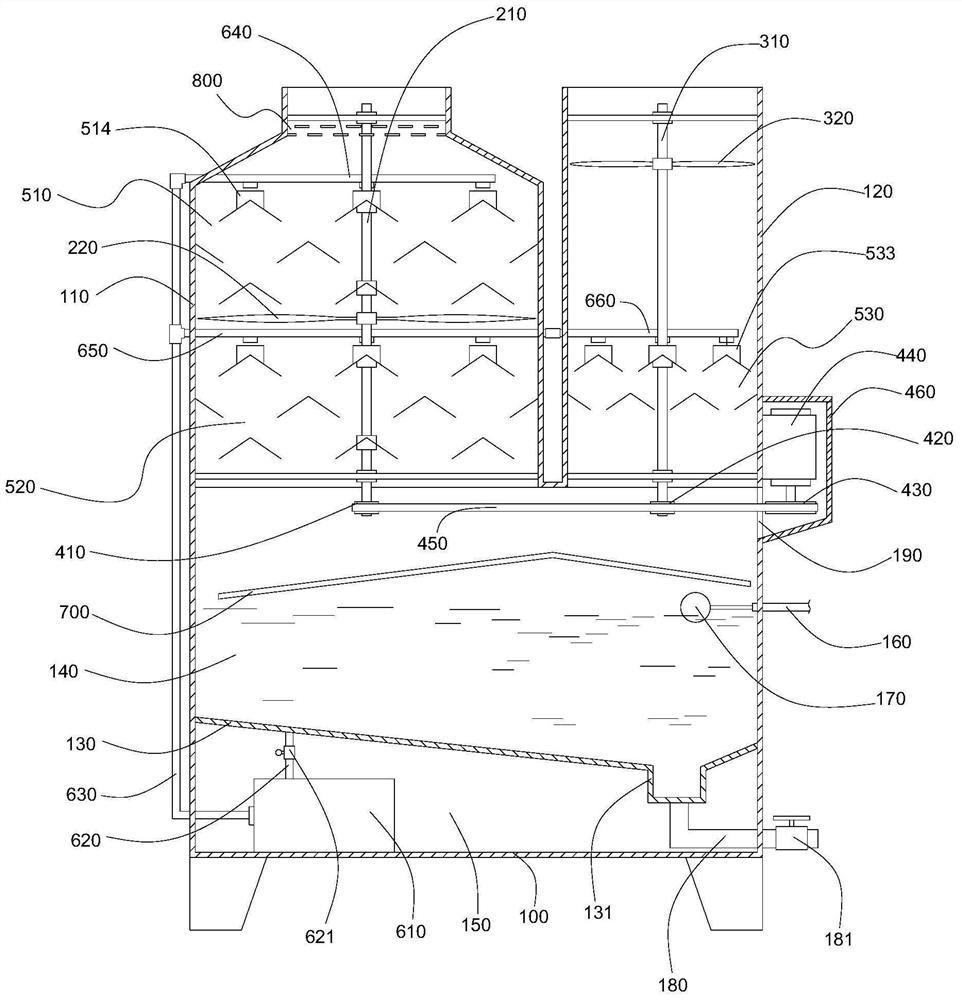

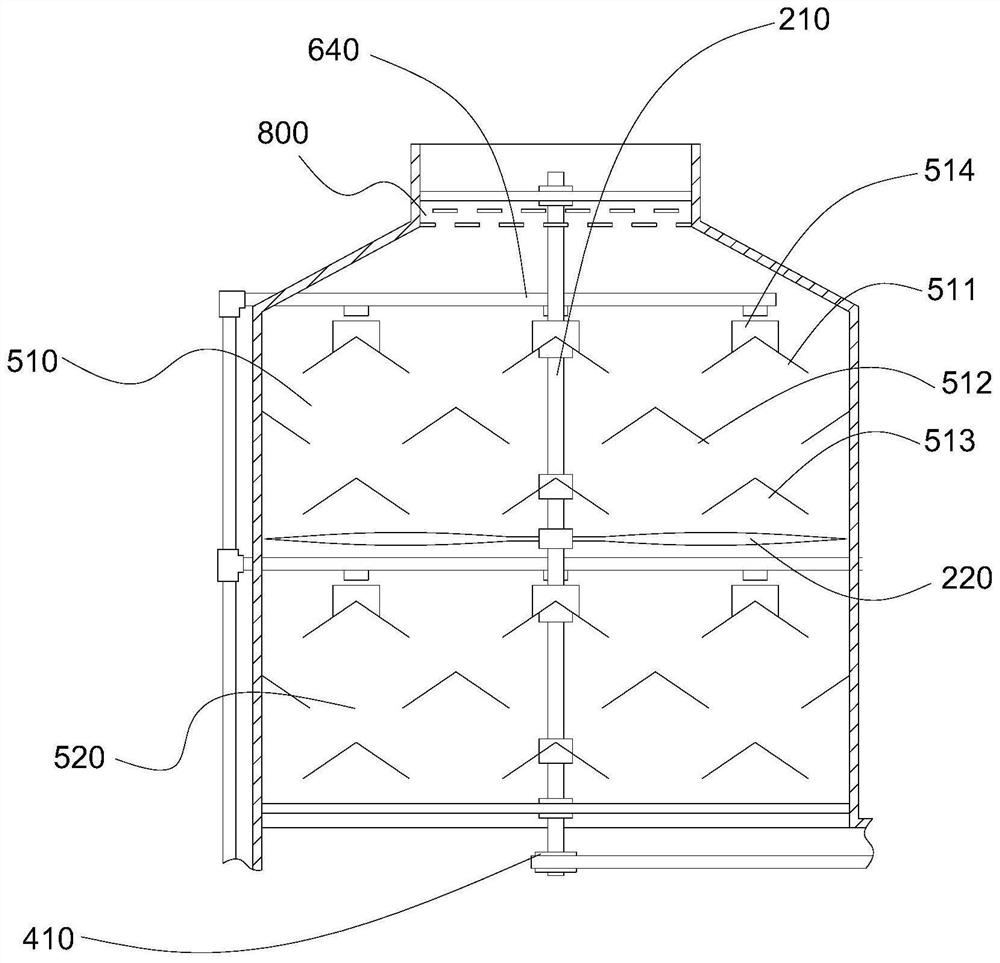

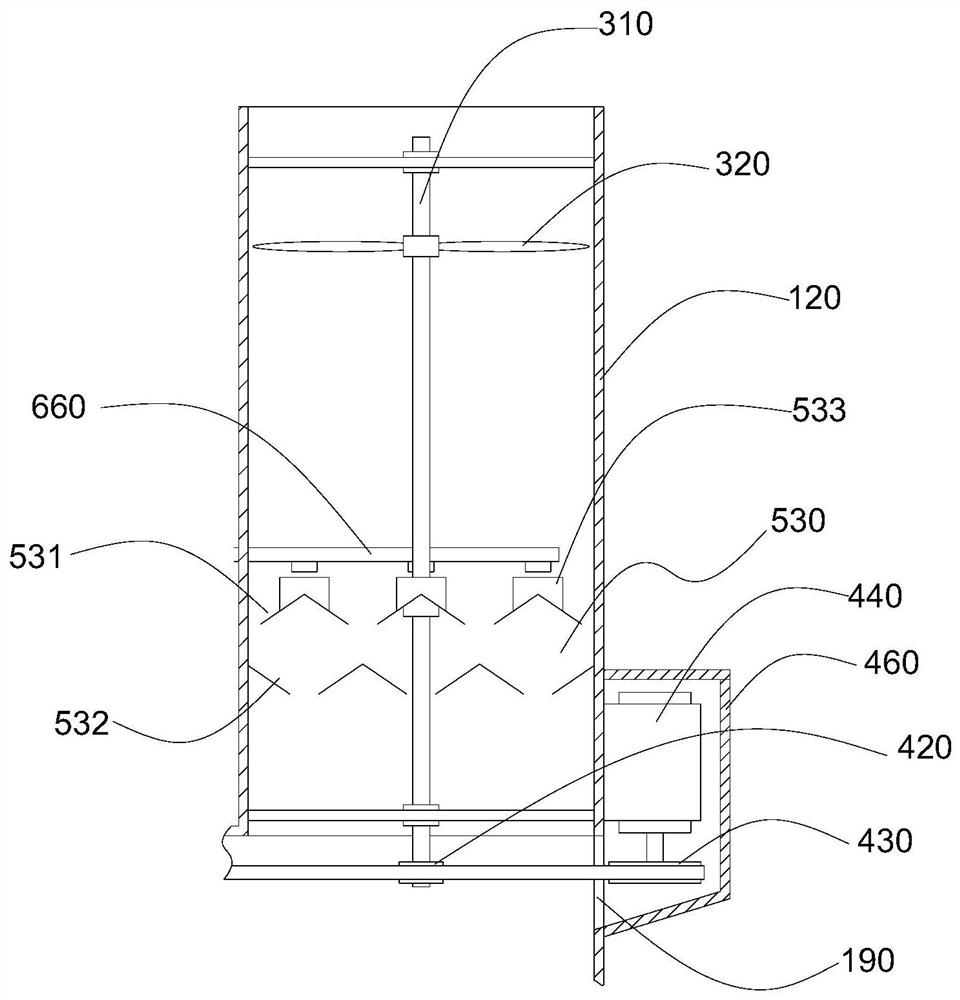

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0021] like Figure 1 to Figure 3 As shown, the technical problem to be solved by the present invention is to propose an array water washing exhaust gas purification device, including a water collection tank 100, which communicates with the first water washing tank 110 and the second water washing tank 120 arranged on the top of the water collection tank 100, and the first water washing tank 120 A first rotating shaft 210 vertically arranged is installed in a water washing box 110, and a first fan blade 220 is fixedly arranged on the first rotating shaft 210, and a second vertically arranged second blade 220 is installed in the described second washing box 120. The rotating shaft 310, the second rotating shaft 310 is fixed with the second fan blade 320, the first rotating shaft 210 and the second ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com