An ink color matching system for a digital printing machine

A printing machine and printing mechanism technology, applied to printing machines, general parts of printing machinery, printing, etc., to achieve the effects of low penetration, balanced humidity, and improved printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

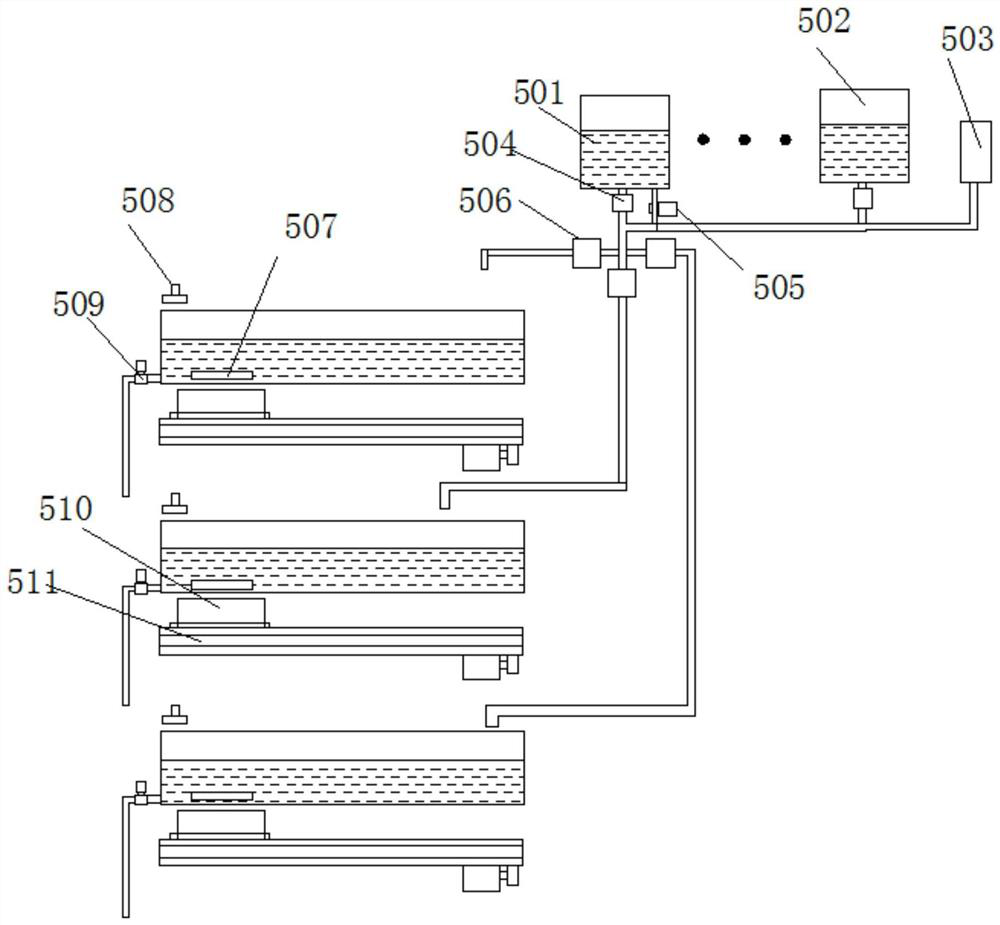

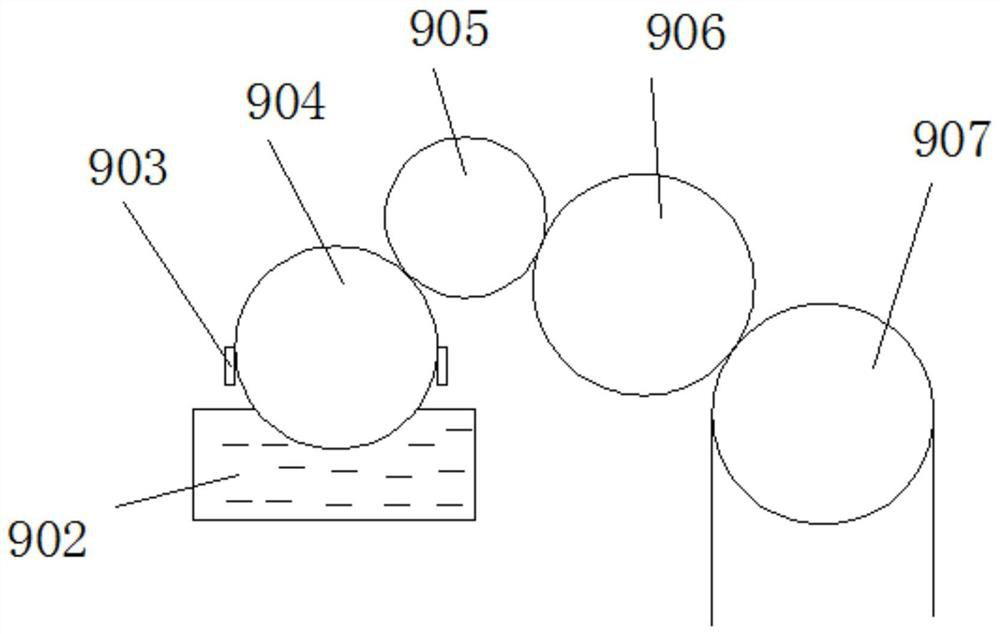

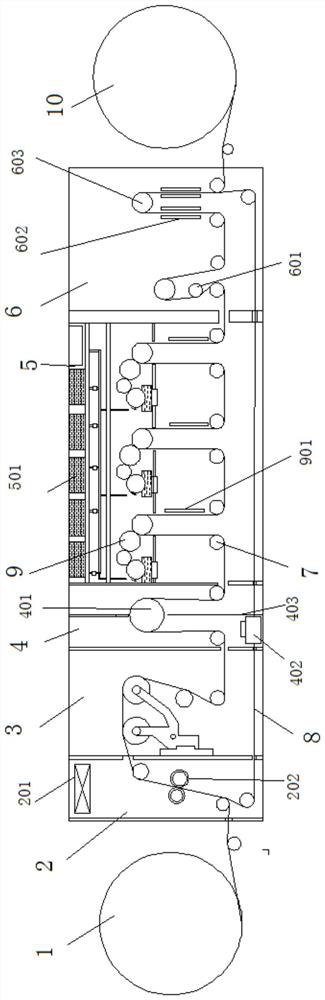

[0028] As shown in the drawings, a corrugated paperboard printing apparatus based on digital printing techniques comprising a feed mechanism 1, a collecting mechanism 10, and a cabinet, and is arranged from left to right in the printed direction of the cabinet. The dust collecting chamber 2, the adjustment control chamber 3, the humidification chamber 4, the printing chamber 5, and the drying chamber 6; the feed mechanism 1 and the collector 10 are respectively used to accommodate the flexible flip before and after printing.

[0029] A dust collecting fan 201 and two dust removal rollers 202 are provided in the dust collecting chamber 2, and the flexible surface paper passes through the related position of the two dust removal rollers 202, and the two dust removal rollers 202 are driven by the corresponding dust removal motor, respectively. Turn to the movement direction of the flexible paper; the dust fan 201 is disposed at the top of the dust collecting chamber 2 and blows downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com