Ink color matching system of digital printer

A technology of printing machines and printing mechanisms, applied in printing machines, general parts of printing machinery, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

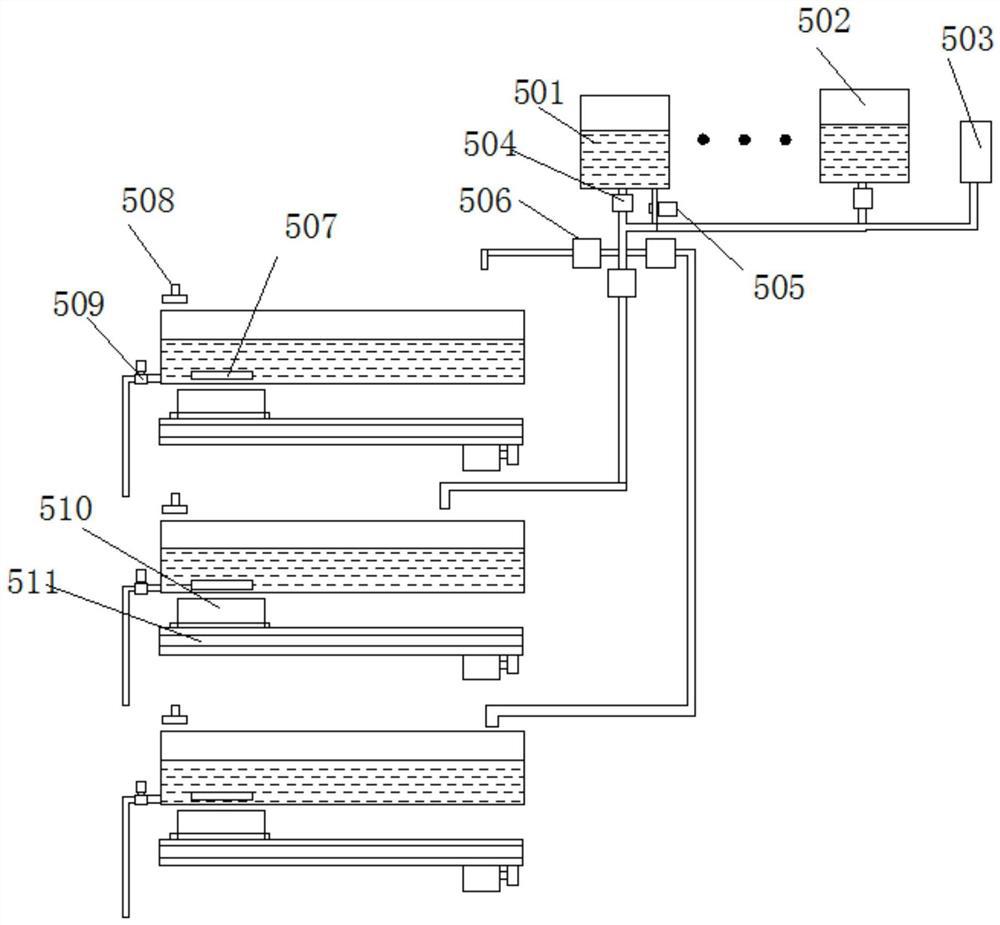

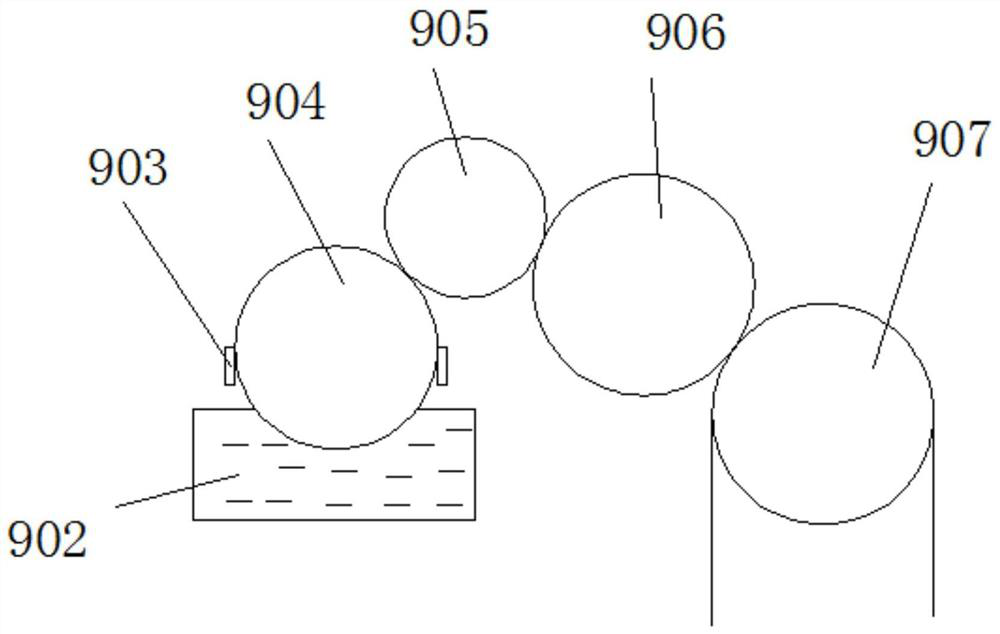

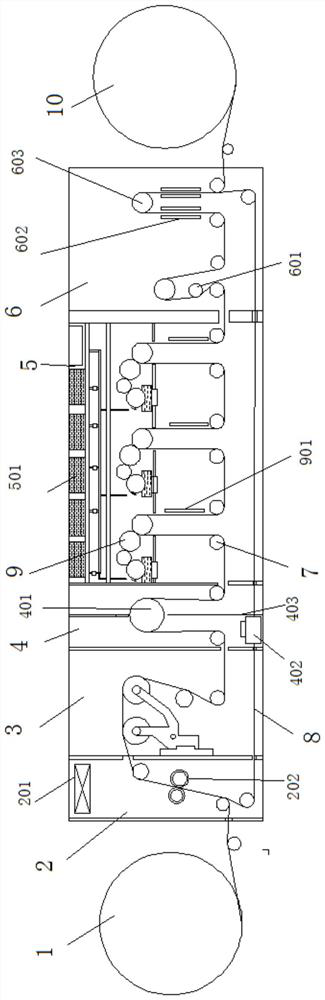

[0029] As shown in the drawings, a corrugated cardboard face paper printing device based on digital printing technology of the present invention includes a feeding mechanism 1, a receiving mechanism 10 and a cabinet, and in the cabinet along the printing direction, there are respectively arranged from left to right. The dust removal room 2, adjustment control room 3, humidification room 4, printing room 5 and drying room 6; the feeding mechanism 1 and the receiving mechanism 10 are respectively used to store the flexible face paper before and after printing.

[0030] In the dust removal chamber 2, a dust removal fan 201 and two dust removal brush rollers 202 are arranged, and the flexible face paper passes through the tangent positions of the two dust removal brush rollers 202, and the two dust removal brush rollers 202 are respectively driven by corresponding dust removal motors and Rotate towards the moving direction of the flexible tissue paper; the dust removal fan 201 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com