Auxiliary rice bagging device

A bagging device and paddy technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems of wasting labor and low efficiency of bagging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

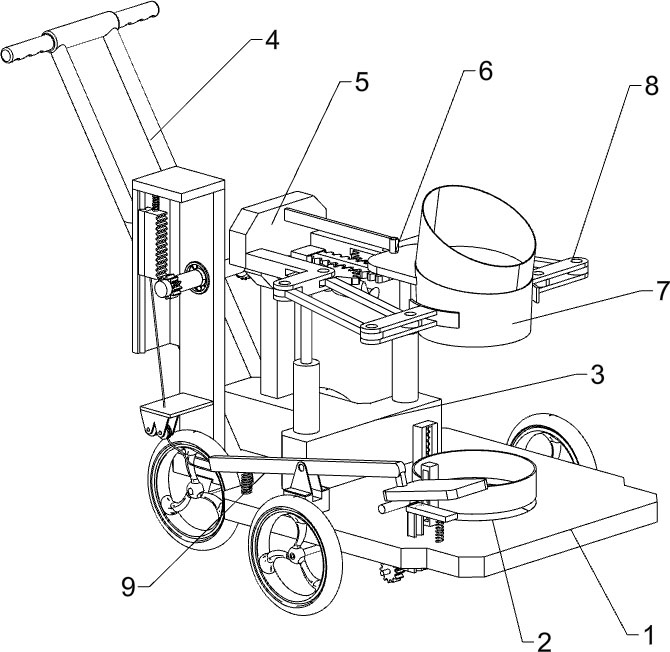

[0024] Such as Figure 1-4 As shown, a rice auxiliary bagging device includes a vehicle frame 1, a cylindrical tube 2, a mounting frame 3, a push rod 4, a first mounting plate 5, a connecting rod 6, a material guide pipe 7, a clamping device 8 and a foot Pedal device 9, the center of the right side of the frame 1 is embedded with a cylinder 2, the center of the left side of the top of the frame 1 is provided with a mounting frame 3, the center of the top left side of the frame 1 is provided with a push rod 4, and the push rod 4 is located on the mounting frame 3 on the left side, the left side of the top of the mounting frame 3 is provided with a first mounting plate 5, the upper right side of the first mounting plate 5 is provided with a connecting rod 6, the right end of the connecting rod 6 is provided with a material guide tube 7, and the right end of the first mounting plate 5 is A clamping device 8 that cooperates with the outer wall of the material guide pipe 7 is provi...

Embodiment 2

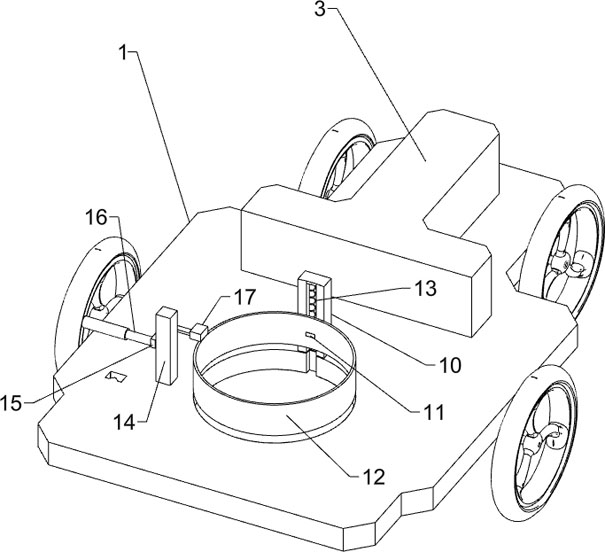

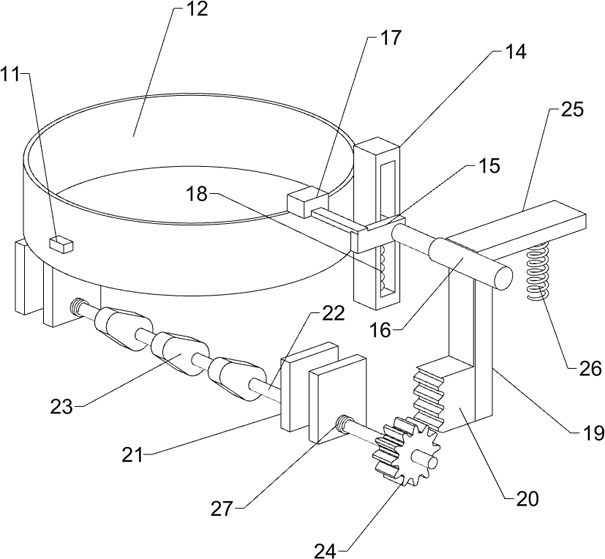

[0029] On the basis of Example 1, such as Figure 5-7 As shown, it also includes a second sliding rail 10, a second sliding block 11, an annular pressure cylinder 12, a third elastic member 13, a third sliding rail 14, a third sliding block 15, a pressing rod 16, a connecting block 17 and a first Four elastic members 18, the center of the top of the vehicle frame 1 is provided with a second slide rail 10, the second slide rail 10 is slidably provided with a second slide block 11, and the second slide block 11 is provided with an annular pressing cylinder 12, and the annular pressing cylinder The central axis of 12 coincides with the central axis of cylinder 2, and a third elastic member 13 is arranged between the second slide rail 10 and the second slider 11. The third elastic member 13 is a tension spring. The third slide rail 14 is arranged on the top of the third slide rail 14, and the third slide block 15 is slidably arranged on the third slide rail 14. The third slide blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com