Buffer member and buffer member forming material

A buffer member and buffer chamber technology, which can be used in household components, special packaging objects, packaged food, etc., and can solve problems such as insufficient buffer function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described with reference to the drawings. In addition, in the drawings referred to below, the same reference numerals are attached to the same or corresponding members.

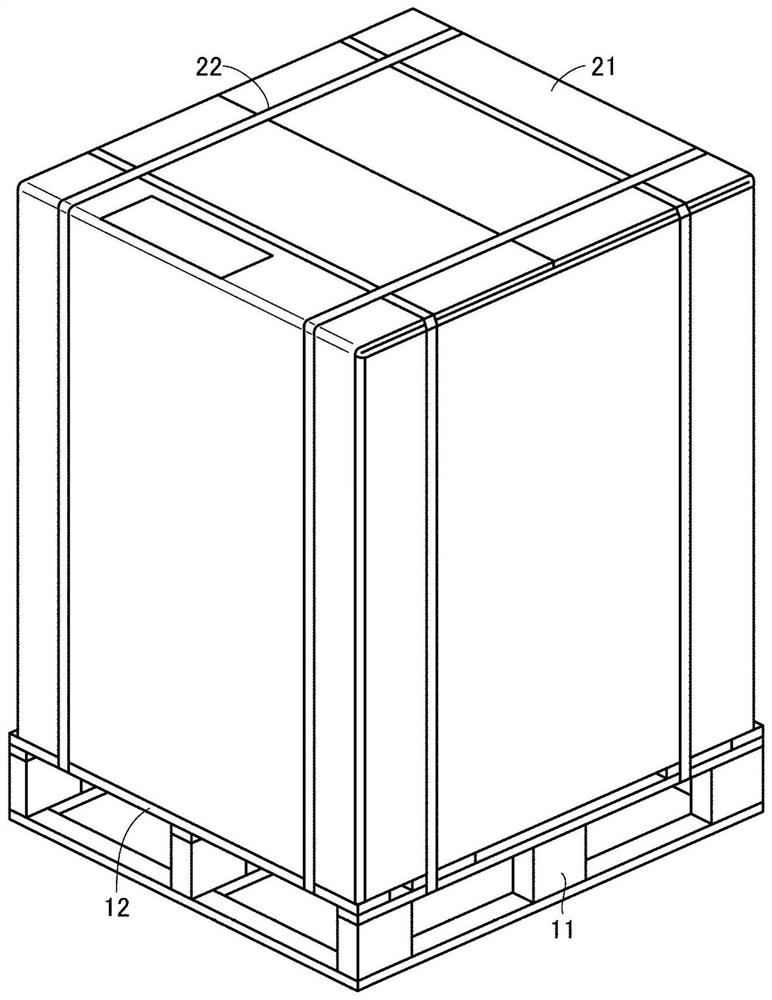

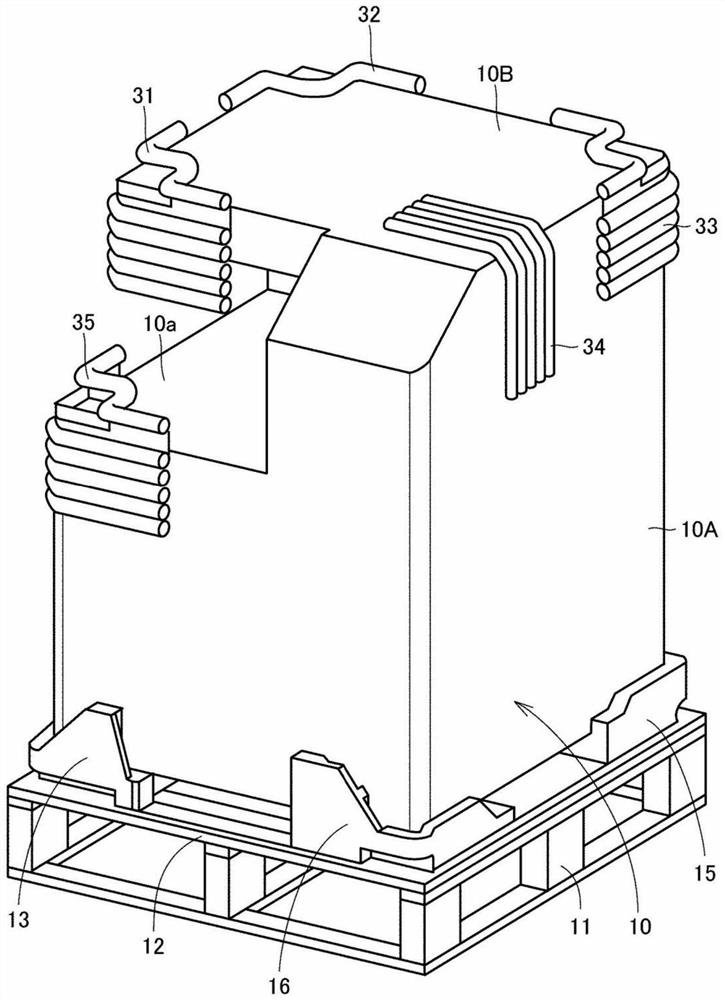

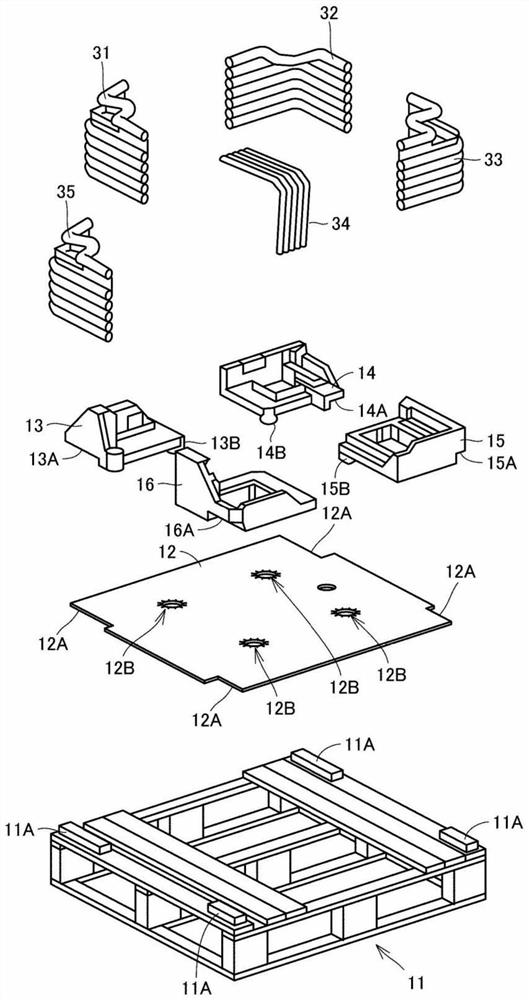

[0045] figure 1 It is a perspective view schematically showing a packaging state of an image forming apparatus according to an embodiment of the present invention in an outer packaging box. figure 2 is shown from figure 1 The packing state shown is a picture of the state with the outer packing box removed. image 3 is for packaging figure 2 An exploded perspective view of various components used in the illustrated image forming apparatus. Below, refer to Figure 1 ~ Figure 3 , the packaged state of the packaged image forming apparatus 10 will be described.

[0046] Such as Figure 1 ~ Figure 3 As shown, when packaging the image forming apparatus 10 , a tray 11 , a plate-shaped mat 12 , a plurality of foams 13 to 16 , a plurality of cushioning member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com