Primary and secondary vehicle equipment for brick making system

A technology of mother car and child car, which is applied in the direction of manufacturing tools, conveyor objects, unloading devices, etc., and can solve the problems of inaccurately limited moving paths, difficult entry and exit of transfer car facilities, and reduced transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content, features and effects of the present invention, the following examples are given in detail.

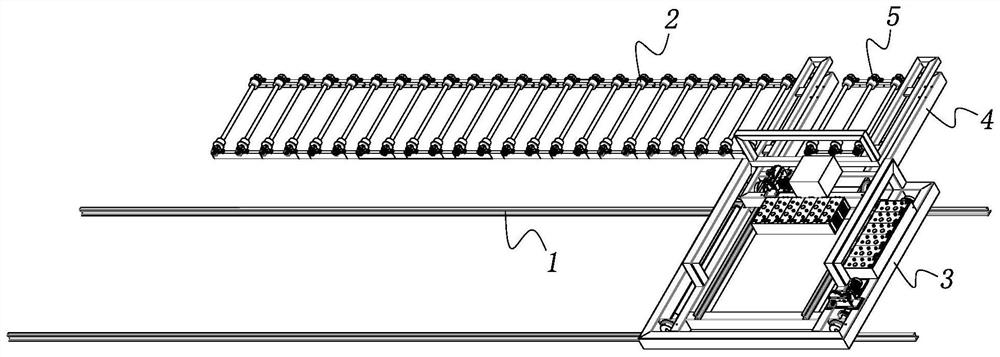

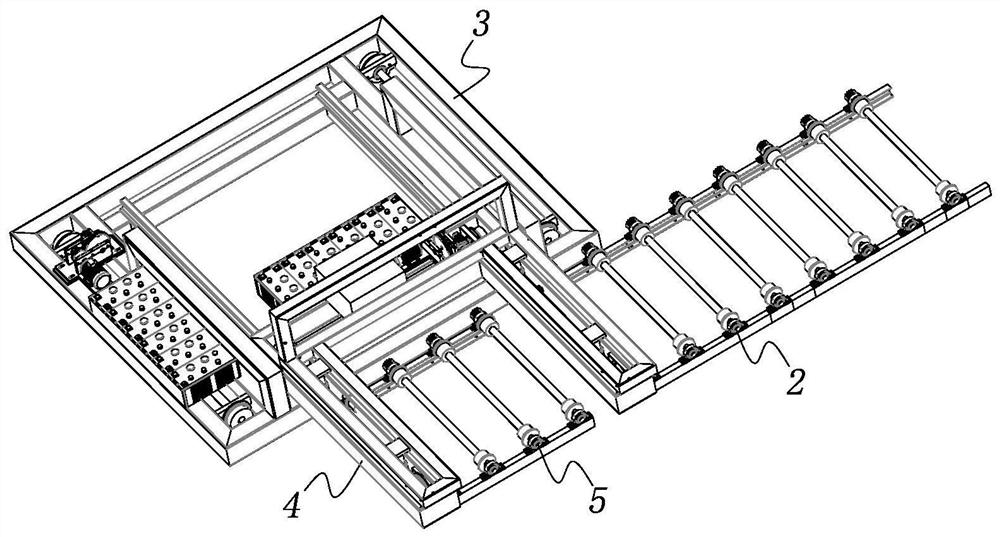

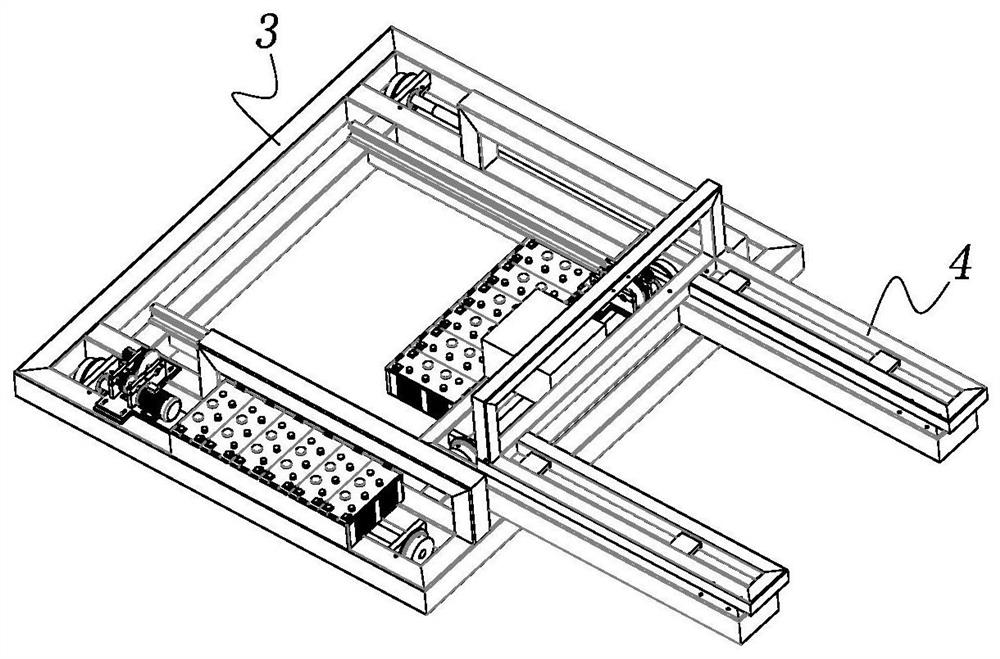

[0028] See figure 1 and figure 2 , the master car equipment for brick making system of the present invention comprises the walking track 1 and the brick board conveying track 2 that are arranged in parallel, is provided with the mother car device 3 on the travel track 1, is installed with the child car on the mother car device 3 device 4.

[0029] Among them, the walking track 1 provides a definite straight moving path for both the parent car device 3 and the sub-car device 4, and the brick plate conveying track 2 is used for horizontally transporting the brick plate (combination of brick adobe and brick supporting plate). The plate conveying track 2 is docked with the brick discharging device of the brick machine equipment, the mother car device 3 moves along the running track 1, and the sub-car device 4 drives into or out of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com