A method for recovering blue iron ore from sludge incineration ash

A technology of sludge incineration and blue iron ore, applied in separation methods, chemical instruments and methods, combustible gas purification/transformation, etc., can solve problems such as long time, and achieve the effect of convenient operation, simple process flow, and elimination of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

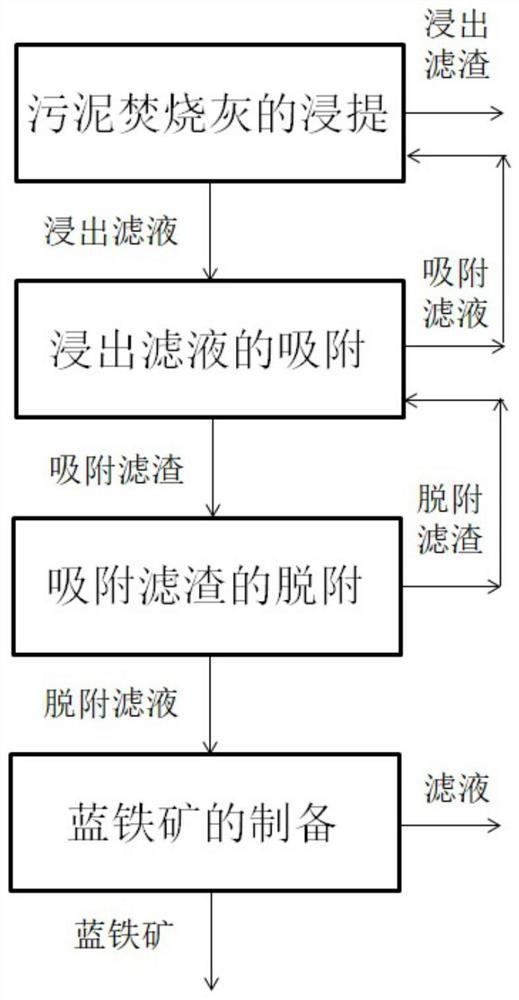

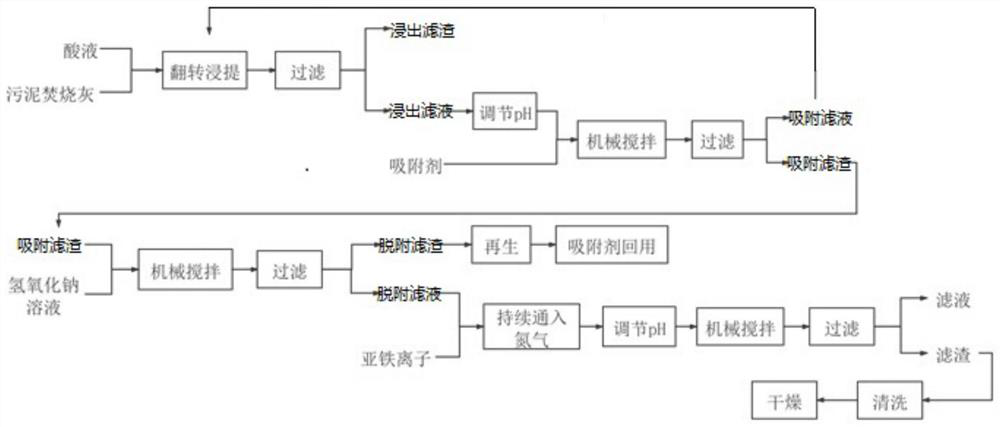

[0038] A method for recovering blue iron ore from sludge incineration ash, the processing object is sludge incineration ash of a sewage treatment plant, X-ray fluorescence spectrum (XRF) detection shows that the mass percentage content of phosphorus in the sludge incineration ash is 5.2 %. Phosphorus is recovered from this kind of sludge incineration ash to prepare blue iron ore, such as figure 1 ,2 As shown, the method specifically includes the following steps:

[0039] (1) Mix and heat 100g of sludge incineration ash and 2L of hydrochloric acid solution (0.5mol / L) (that is, the liquid-solid ratio is 0.02L / g), and turn over and leaching at 30°C (the frequency of turning and leaching refers to what is often used in the prior art) parameters, the same below) after 0.5h, the mixture was filtered to obtain leaching filtrate and leaching filter residue.

[0040] (2) Get the leach filtrate that 100mL step (1) obtains and 4g magnesium iron hydrotalcite (that is, the liquid-solid r...

Embodiment 2

[0048] The invention discloses a method for recovering blue iron ore from sludge incineration ash, and the processing object is the sludge incineration ash of a certain sewage treatment plant. X-ray fluorescence spectrum (XRF) detection showed that the phosphorus content of the sludge incineration ash was 5.2wt%. Reclaim phosphorus from this kind of sludge incineration ash, prepare blue iron ore, specifically comprise the following steps:

[0049] (1) Mix and heat 100g of sludge incineration ash and 2L of hydrochloric acid solution (0.3mol / L) (that is, the liquid-solid ratio is 0.02L / g), and after flipping and leaching at 55°C for 0.5h, filter the mixture to obtain the leaching filtrate and leached filter residue.

[0050] (2) Take 150mL of the leachate obtained in step (1) and 6g of magnesium iron hydrotalcite (that is, the liquid-solid ratio is 0.025L / g) in the reactor, and adjust the pH value of the mixed solution to 5 with 0.2mol / L sodium hydroxide solution , and mechani...

Embodiment 3

[0058] The invention discloses a method for recovering blue iron ore from sludge incineration ash, and the processing object is the sludge incineration ash of a certain sewage treatment plant. X-ray fluorescence spectrum (XRF) detection showed that the phosphorus content of the sludge incineration ash was 5.3wt%. Reclaim phosphorus from this kind of sludge incineration ash, prepare blue iron ore, specifically comprise the following steps:

[0059] (1) Mix and heat 100g of sludge incineration ash and 1L of hydrochloric acid solution (0.3mol / L) (that is, the liquid-solid ratio is 0.01L / g), and after leaching at 55°C for 2 hours, filter the mixture to obtain the leaching filtrate and Leach out the filter residue.

[0060] (2) Take 250mL of the leaching solution obtained in step (1) and 10g of magnesium iron hydrotalcite (that is, the liquid-solid ratio is 0.025L / g) in the reactor, and adjust the pH value of the mixed solution to 6 with 0.2mol / L sodium hydroxide solution , and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com