Construction quality control device for solidified soil pile and construction method thereof

A control device and construction quality technology, which is applied in the field of solidified soil pile construction quality control devices, can solve the problems of uneven mixing of solidifying agent and soil, low strength of solidified soil in pile body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

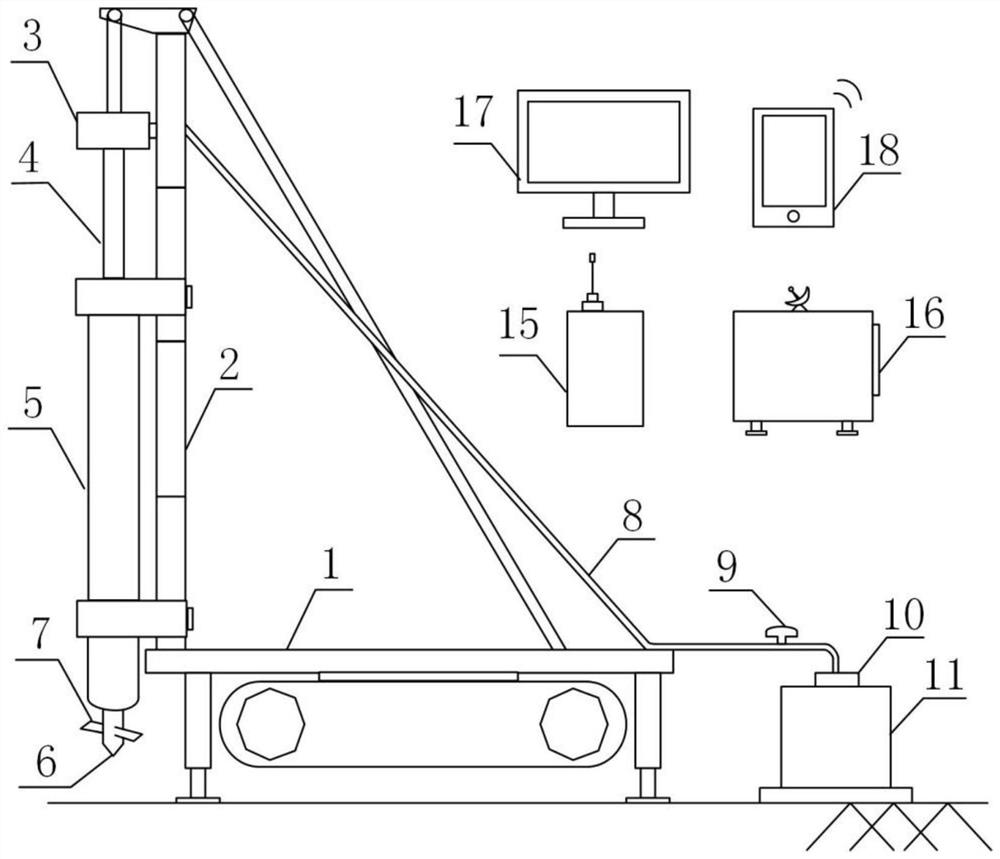

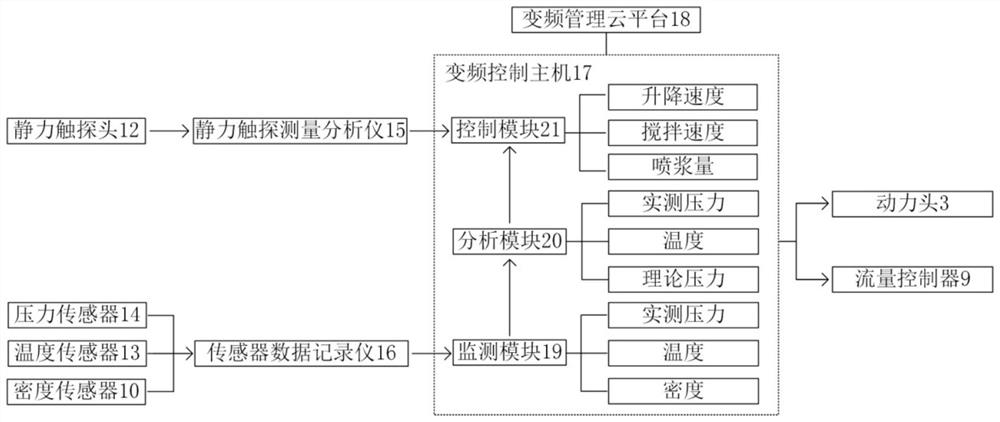

[0042] This embodiment provides a construction method of a solidified soil pile construction quality control device, comprising the following steps:

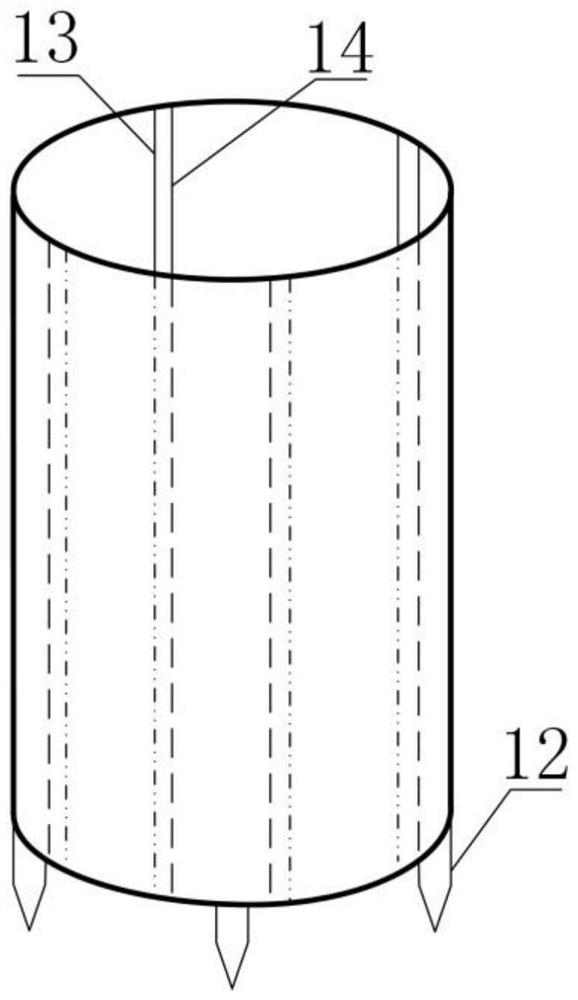

[0043] Step 1, three connections and one leveling, measurement and stakeout, pile driver 1, curing agent 12, frequency conversion control host 17 and frequency conversion management cloud platform 18 are in place. The pile frame 2 is moved to the designated position and centered, and the casing 5 is installed. In this embodiment, the pile driver 1 is a cement mixing pile driver.

[0044] Step 2: Start the cement mixing pile machine, the casing 5 is cut and drilled under the action of the power head 3, the static contact measurement analyzer 15 wirelessly receives the measurement data of the static contact probe 12 at the bottom of the casing 5, and the static contact measurement The analyzer 15 judges the properties of the soil layer in combination with the geological survey report, and the static contact measurement analyzer 1...

Embodiment 2

[0052] This embodiment provides a construction method of a solidified soil pile construction quality control device, comprising the following steps:

[0053] Step 1, three connections and one leveling, measurement and stakeout, pile driver 1, curing agent 12, frequency conversion control host 17 and frequency conversion management cloud platform 18 are in place. The pile frame 2 is moved to the designated position and centered, and the casing 5 is installed. In this embodiment, the pile driver 1 is a rotary spray pile driver.

[0054] Step 2: Start the rotary grouting pile machine, the casing 5 is cut and drilled under the action of the power head 3, the static contact measurement analyzer 15 wirelessly receives the measurement data of the static contact probe 12 at the bottom of the casing 5, and the static contact measurement The analyzer 15 judges the properties of the soil layer in combination with the geological survey report, and the static contact measurement analyzer ...

Embodiment 3

[0062] Step 1, three connections and one leveling, measurement and stakeout, pile driver 1, curing agent 12, frequency conversion control host 17 and frequency conversion management cloud platform 18 are in place. The pile frame 2 is moved to the designated position and centered, and the casing 5 is installed.

[0063] Step 2: start the pile driver, the casing 5 is cut and drilled under the action of the power head 3, the static contact detection analyzer 15 wirelessly receives the measurement data of the static contact probe 12 at the bottom of the casing 5, and the static contact measurement analyzer 15 Combined with the geological survey report to determine the properties of the soil layer, the static contact detection analyzer 15 transmits the measurement data to the control module 21 of the frequency conversion control host 17 via wireless.

[0064] Step 3: The control module 21 sends an instruction to the power head 3 of the pile driver 1 , and the drill pipe 4 and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com