Portable shallow mudstone sampling mechanism

A portable, mudstone technology, used in sampling, sampling devices, instruments, etc., can solve the problems of lack of layering ratio, low hardness, and low accuracy of sampling experiment results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

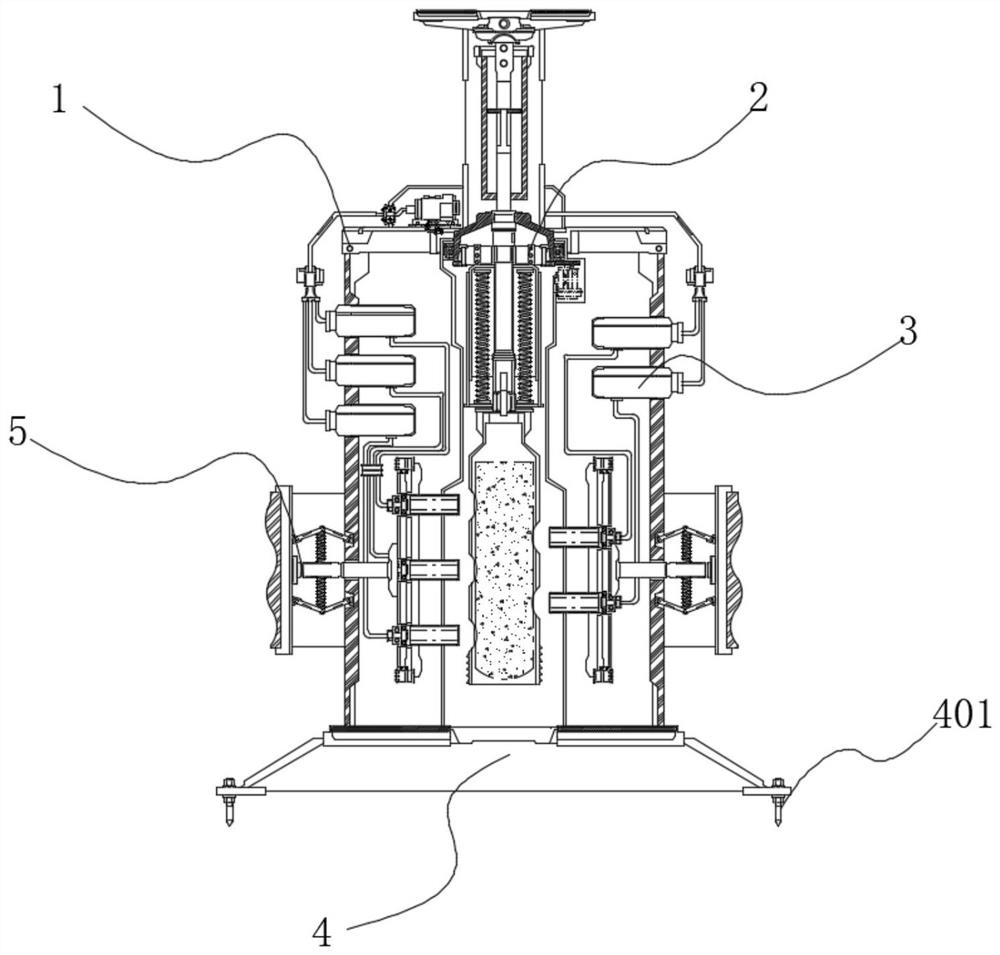

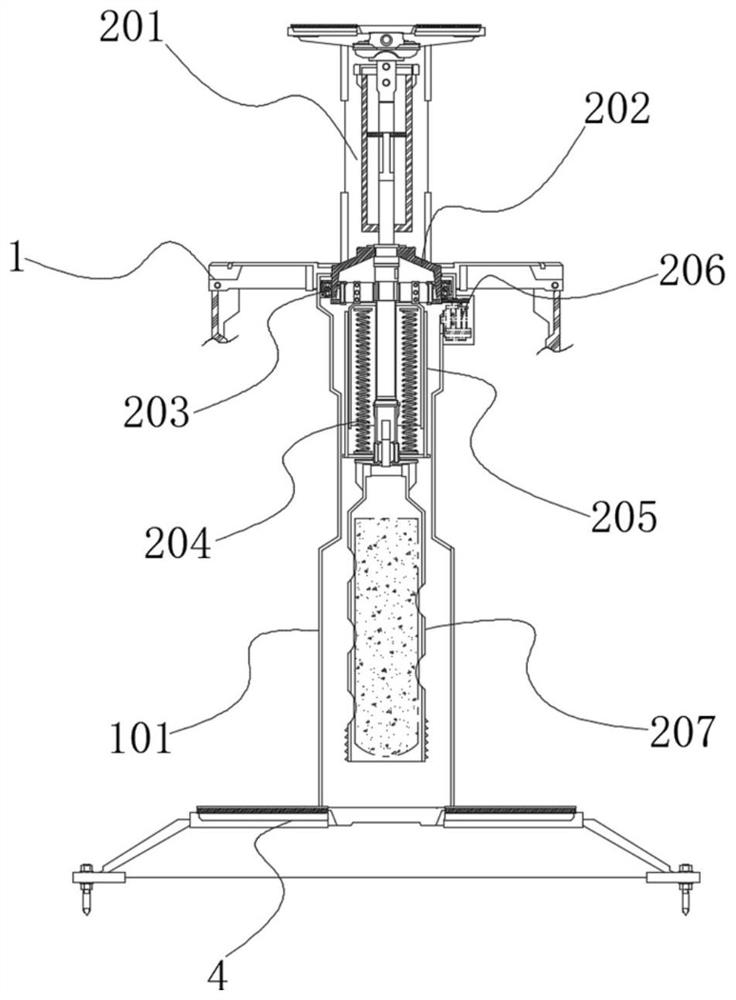

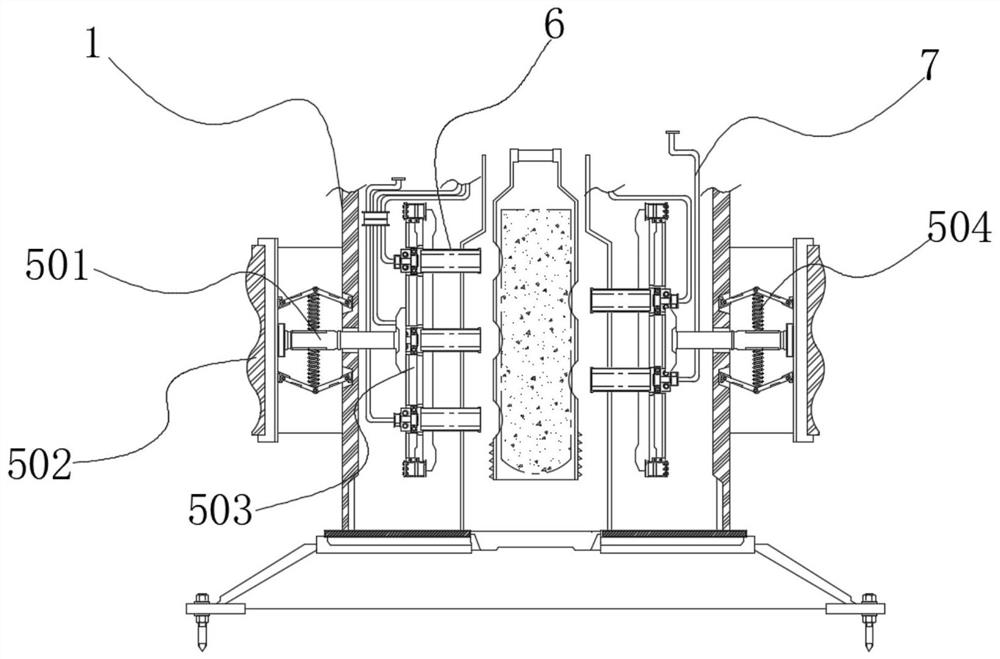

[0031] refer to figure 1 , the present invention provides a technical solution: a portable shallow mudstone sampling mechanism, which includes an outer casing 1, a support seat 4, a built-in sampling component 2, a side extraction component 5 and a storage cylinder seat 3, wherein the The lower end surface of the outer casing 1 is undercut and fixedly provided with a support seat 4. The support seat 4 is fully in contact with the outer surface of the shallow mudstone, and is temporarily inserted and fixed by setting a plurality of fixing pieces 401 on the outside of its circumference. On the shallow mudstone, a built-in sampling component 2 is coaxially arranged in the vertical direction in the outer shell 1,

[0032] The built-in sampling component 2 extends the sampling pipe fitting into the shallow mudstone when performing sampling work, and completely takes out the mudstone sample from the shallow mudstone layer through its rotation and telescopic work; it should be noted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com