Automatic sensing jet-propelled sweeping robot

A sweeping robot and jet technology, applied in the field of robotics, can solve the problems of inability to sweep and wipe the floor, unable to store matches, cigarette butts, sensor damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

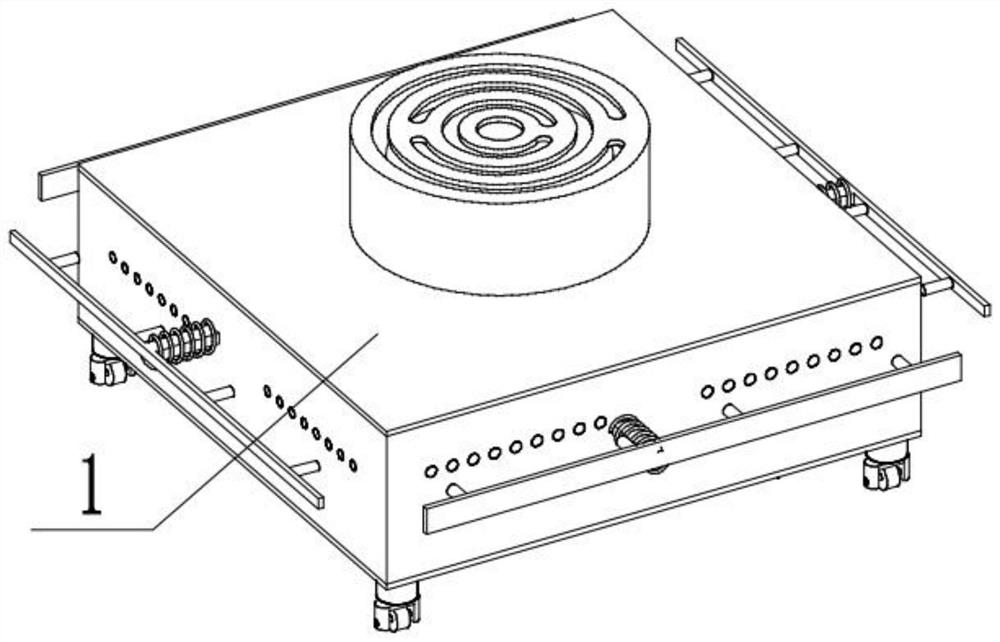

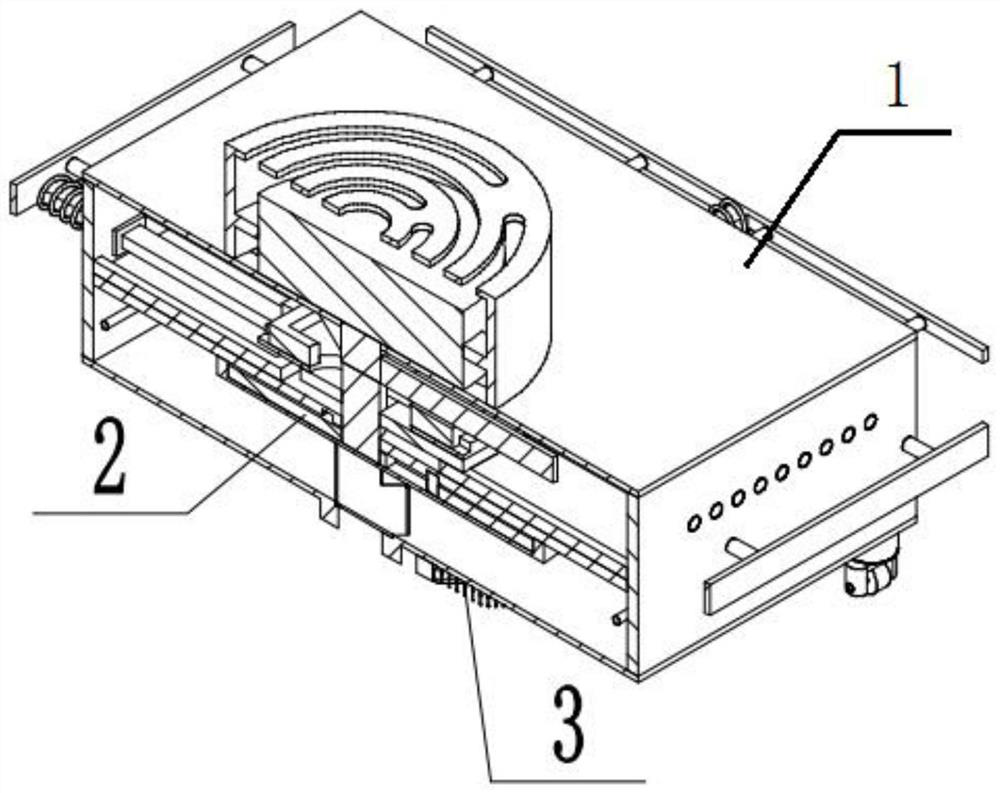

[0035] Combine below Figure 1-20 Describe this embodiment, an automatic sensing jet-type sweeping robot, including a power assembly 1, a dust collection assembly 2, and a mopping assembly 3, and the dust collection assembly 2 and the mopping assembly 3 are all combined with dust collection Body 2 is connected.

specific Embodiment approach 2

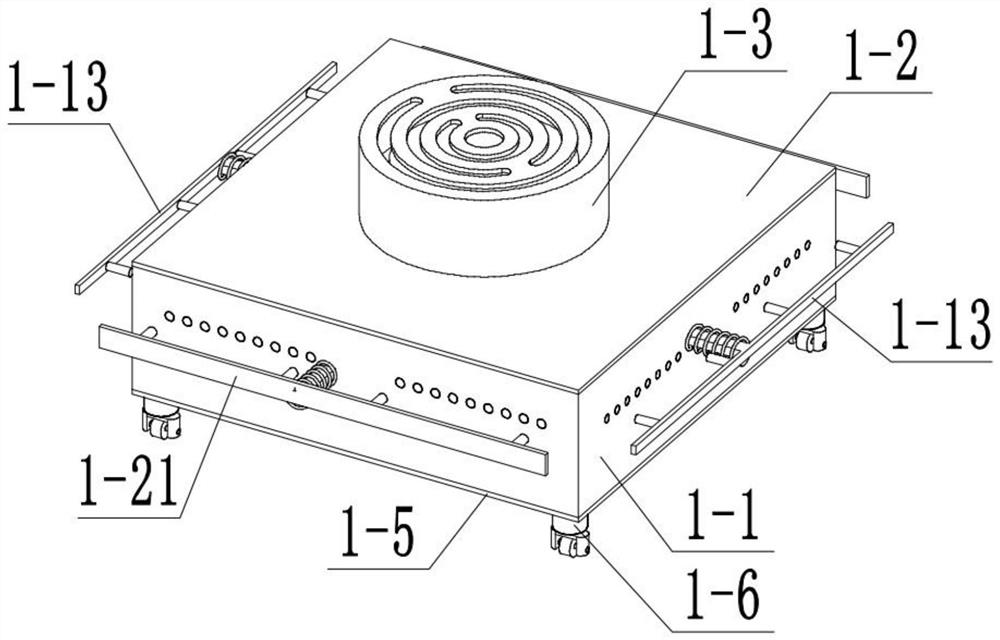

[0037] Combine below Figure 1-20Describe this embodiment, this embodiment will further explain the first embodiment, the power assembly 1 includes a box body 1-1, an upper end cover 1-2, a motor cover 1-3, a motor bracket 1-4, a lower end cover 1- 5. Travel wheel fixing block 1-6, travel wheel bracket 1-7, travel wheel shaft 1-8, travel wheel 1-9, motor 1-10, motor shaft 1-11, fan blade 1-12, induction plate Ⅰ1- 13. Inclined rod Ⅰ1-14, inclined rod limit piece Ⅰ 1-15, spring Ⅰ1-16, reset column Ⅰ1-17, upper slide 1-18, jet control blocking rod Ⅰ1-19, upper slide limit bracket 1- 20. Induction plate Ⅱ1-21, slanting rod Ⅱ1-22, slanting rod limit piece Ⅱ1-23, spring Ⅱ1-24, reset column Ⅱ1-25, sliding plate 1-26, jet control blocking rod Ⅱ1-27, sliding plate The limit bracket 1-28 and the dust suction port 1-29, the box body 1-1 is connected with the upper end cover 1-2, the upper end cover 1-2 is connected with the motor cover 1-3, and the motor cover 1-3 is connected with the ...

specific Embodiment approach 3

[0039] Combine below Figure 1-20 Describe this embodiment, this embodiment will further explain Embodiment 1, the dust suction assembly 2 includes a middle partition 2-1, an air injection port 2-2, a handle I 2-3, a magnetic blocking plate 2-4, a connecting rod 2- 5. Scraper 2-6, vacuum door 2-7, turntable 2-8, suction shell 2-9, blade 2-10, blade shaft 2-11, blade shaft slide rail 2-12 and filter plate 2- 13. The middle partition 2-1 is connected with the box body 1-1, the air outlet 2-2 is located on the middle partition 2-1, the handle Ⅰ 2-3 is connected with the magnetic blocking board 2-4, and the magnetic blocking board 2- 4 Connect with the connecting rod 2-5, the connecting rod 2-5 is connected with the scraper 2-6, the scraper 2-6 is in contact with the lower end cover 1-5, the suction door 2-7 is connected with the lower end cover 1-5 are hinged, the turntable 2-8 is connected to the motor shaft 1-11, the motor shaft 1-11 is rotatably connected to the middle partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com