Lamp post system based on groove mounting structure

A technology for installing structures and lamp poles, which is applied to the parts of lighting devices, lighting devices, lighting auxiliary devices, etc., and can solve the problems of easy rust, reduced strength, and ugly appearance of lamp poles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

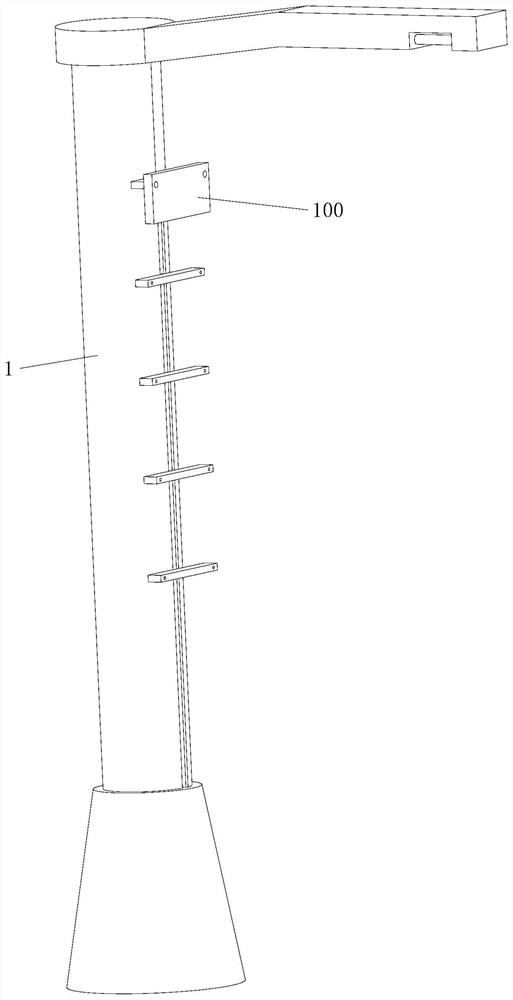

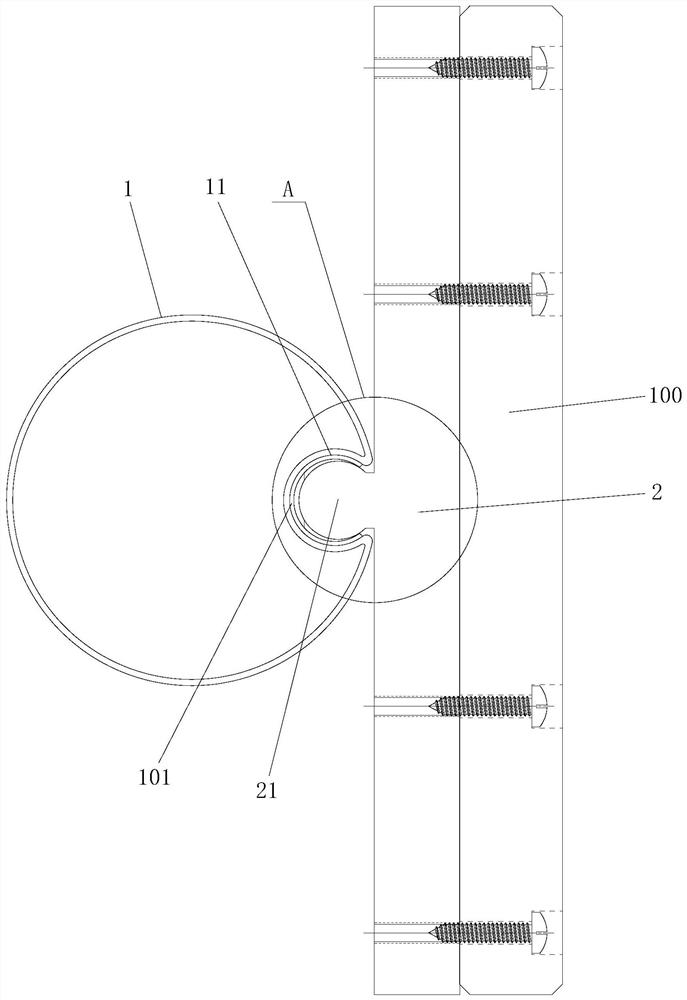

[0034] Such as Figure 1 to Figure 3 As shown, the light pole system based on the groove installation structure of this embodiment includes a light pole main body 1, a plurality of installation bases 2 and a functional part 100. The light pole main body 1 has a installation groove extending along the length direction, The mounting base 2 has a connecting portion 21 placed in the mounting groove, the mounting base 2 is connected with a positioning mechanism for fixing the connecting portion 21 in the mounting groove, and one of the mounting bases 2 is installed with a functional part 100 . The light pole system adopts the light pole main body 1 with a mounting groove, and the connecting part 21 of the mounting base 2 is placed in the mounting groove and fixed by a positioning mechanism. Compared with the traditional installation method, the connecting part 21 is hidden in the mounting groove In addition, the aesthetics can be improved, and the matching structure of the connect...

Embodiment 2

[0041] The light pole system based on the groove installation structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 4 and Figure 5As shown, in the present embodiment, the cross-sections of the bottom groove bottom and the top groove body of the inner expansion groove 11 are rectangular, and the connecting portion 21 can be inserted into the inner expansion groove 11 from the inner expansion groove 11 notch and can be inserted into the inner expansion groove 11. The expansion member positioned between the inner walls on both sides of the inner expansion groove 11 is tightened by rotation. The tensioning member of this embodiment can be a strip, and it is preferable to arrange a tensioning curved surface at both ends of the strip to realize gradual expansion. Specifically, the tensioning member can be a boat nut in the prior art.

[0042] In this embodiment, the connecting part 21 can be inserted into the inner expa...

Embodiment 3

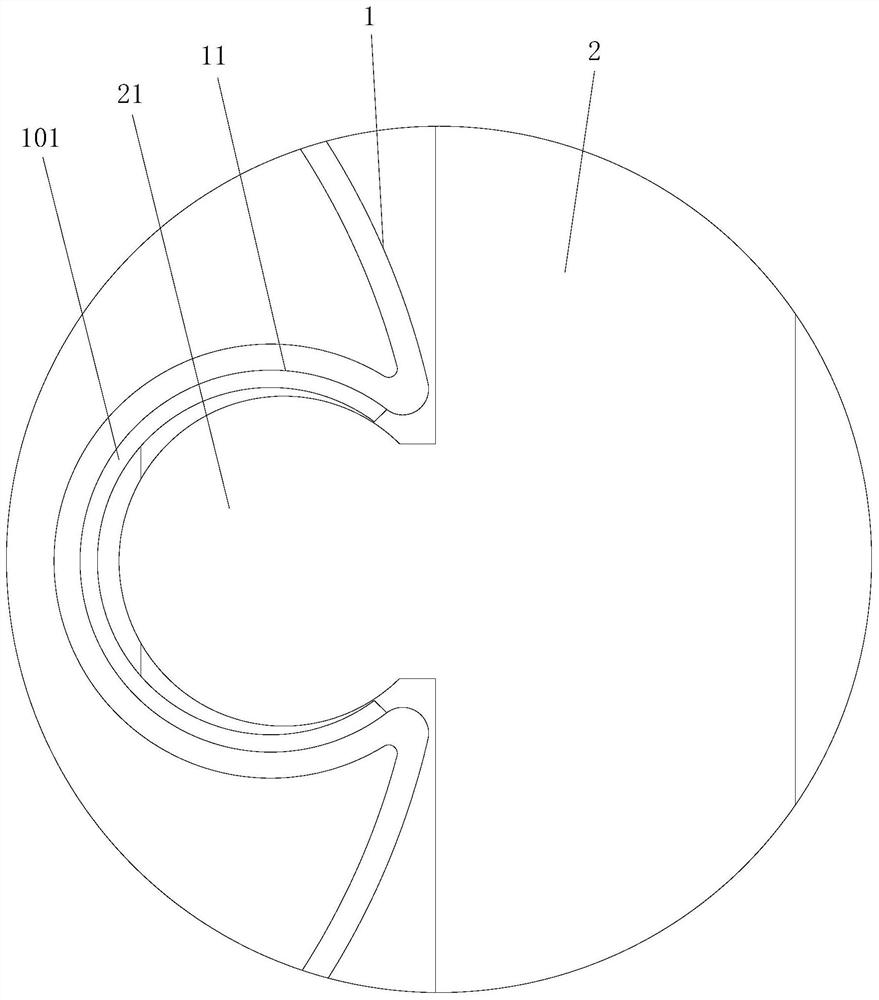

[0044] The light pole system based on the groove installation structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 6 and Figure 7 As shown, in this embodiment, the inner expansion groove 11 is a dovetail groove as a whole, and the positioning mechanism includes a tightening member 102, which is threadedly connected to the mounting base 2, and the tightening member 102 can be screwed to make the The tightening member 102 tightens the inner wall of the inner expansion groove 11 to force the connecting portion 21 to be in close contact with the inner wall of the inner expansion groove 11, or the tightening member 102 is separated from the inner wall of the inner expansion groove 11 so that the connecting portion 21 can move along the inner wall of the inner expansion groove 11. The inner expansion groove 11 moves. When the tightening member 102 tightens the inner wall of the inner expansion groove 11, the tightening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com