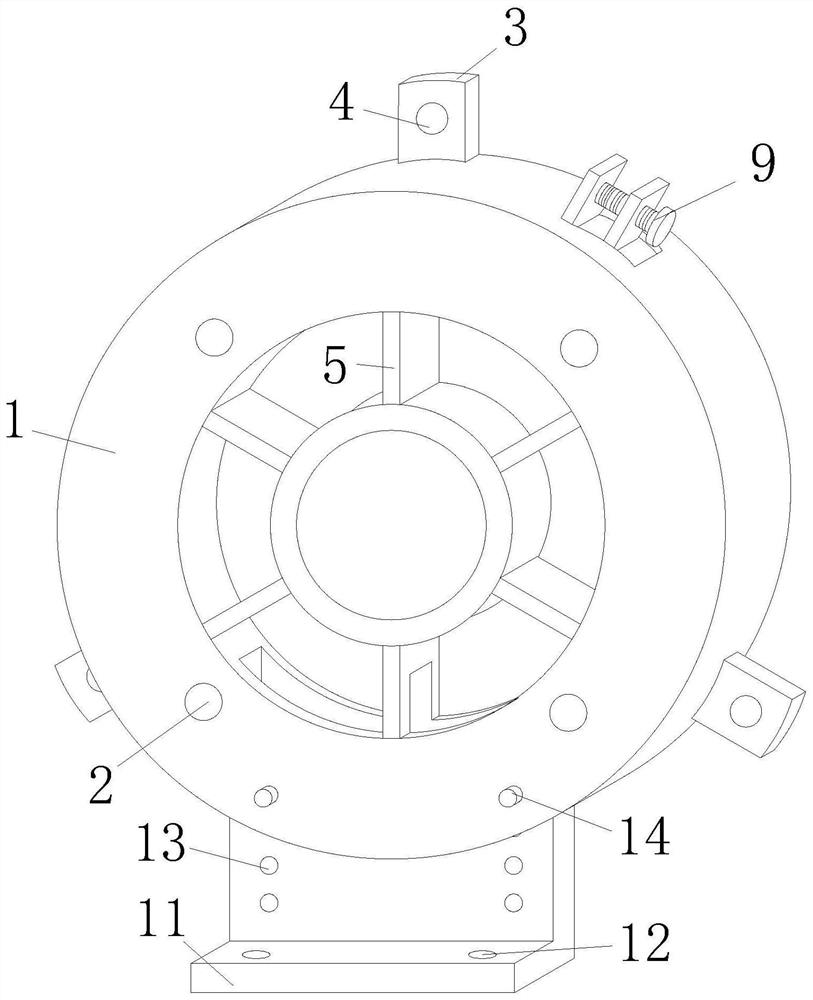

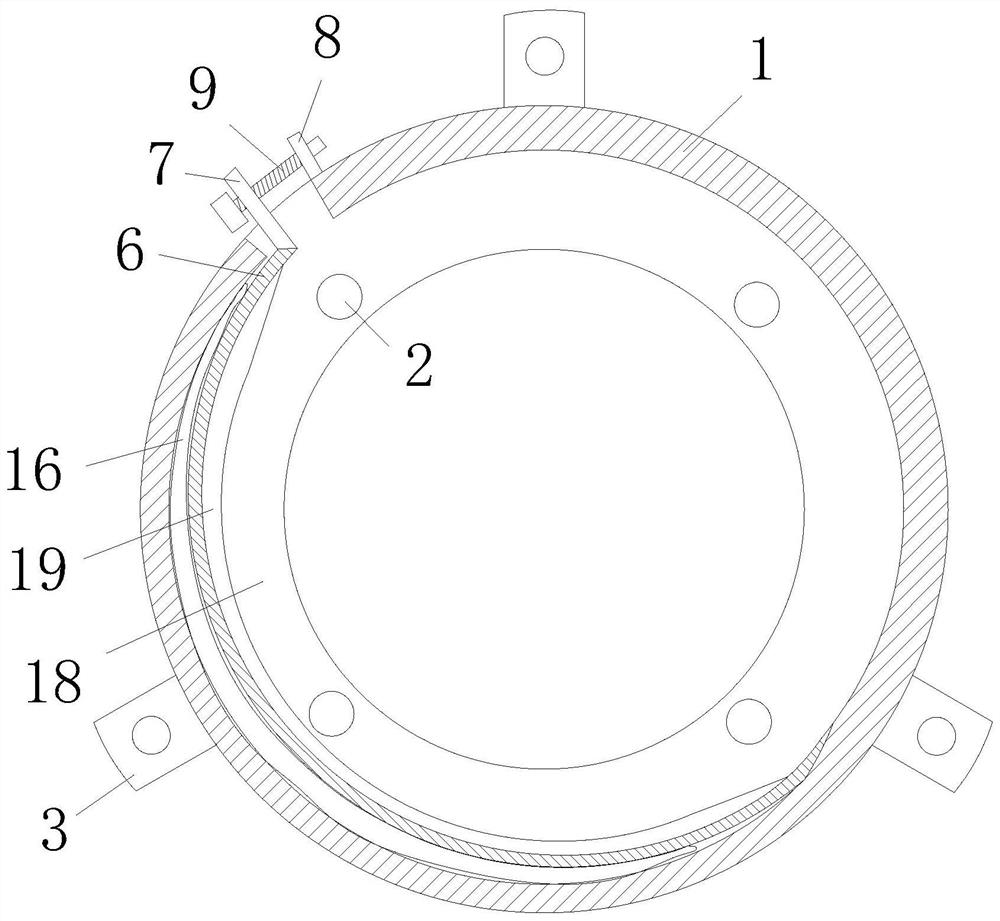

Motor end cover assembly and motor

A technology for motor end caps and end caps, which is applied to electrical components, electromechanical devices, electric components, etc., can solve problems such as reduced fixing strength, unfavorable installation of the main body of the motor, and loose screws on the end cap assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

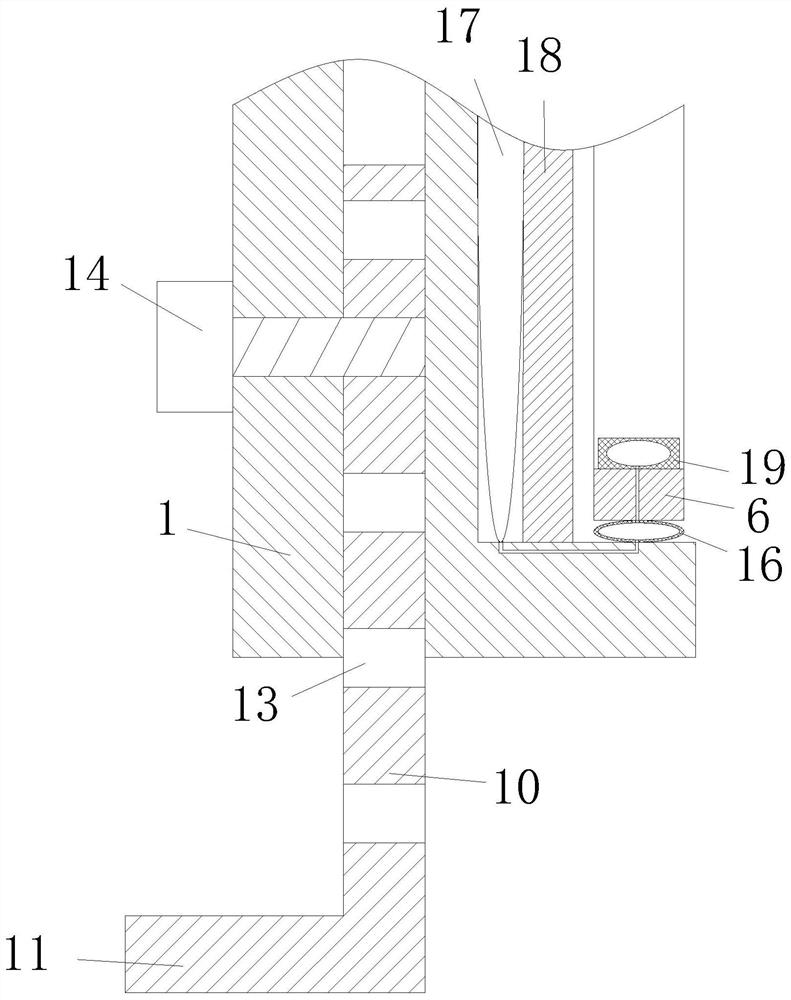

[0023] As an embodiment of the present invention, a buffer pad 19 is fixedly connected to the side of the movable piece 6 away from the first expansion bag 16; a cavity is opened in the buffer pad 19, and the cavity is connected to the first expansion bag 16; During work, the movable piece 6 cooperates with the motor main body 1 to squeeze the buffer pad 19 during the tightening process, so that the gas in the buffer pad 19 enters the first expansion bag 16 and the second expansion bag 17, and the first expansion bag 16 expands to the motor body. The extrusion force of 15, in conjunction with the expansion of the second expansion bag 17 and the extrusion force of the movable piece 6 on the motor body, can further improve the fixing effect between the motor body 15 and the end cover housing 1, and the buffer pad 19 cooperates with the first The expansion bag 16 effectively cushions the motor body 15, further reduces the vibration force transmitted from the motor body 15 to the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com