Cast-in-place pile formwork quick smearing device

A technology of cast-in-place piles and templates, which is applied to the surface coating liquid device, coating, formwork treatment, etc., and can solve the problem of inconvenient application of semicircular formwork release agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

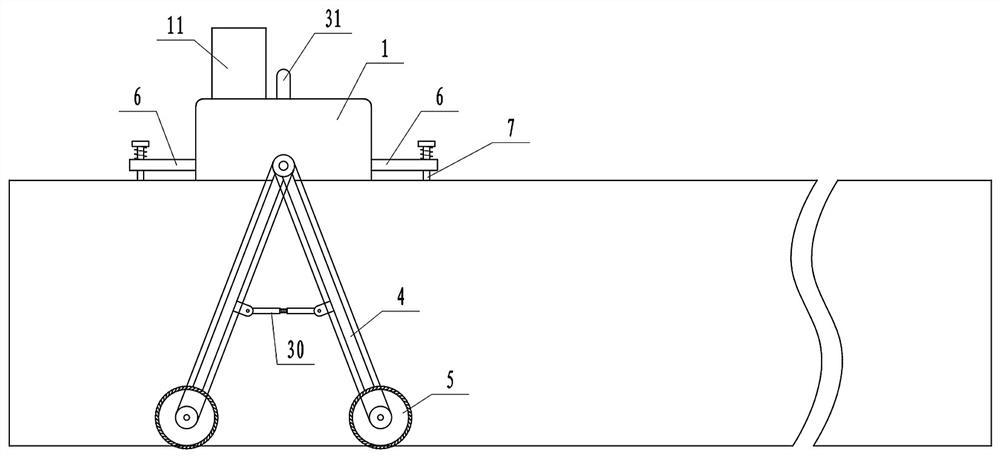

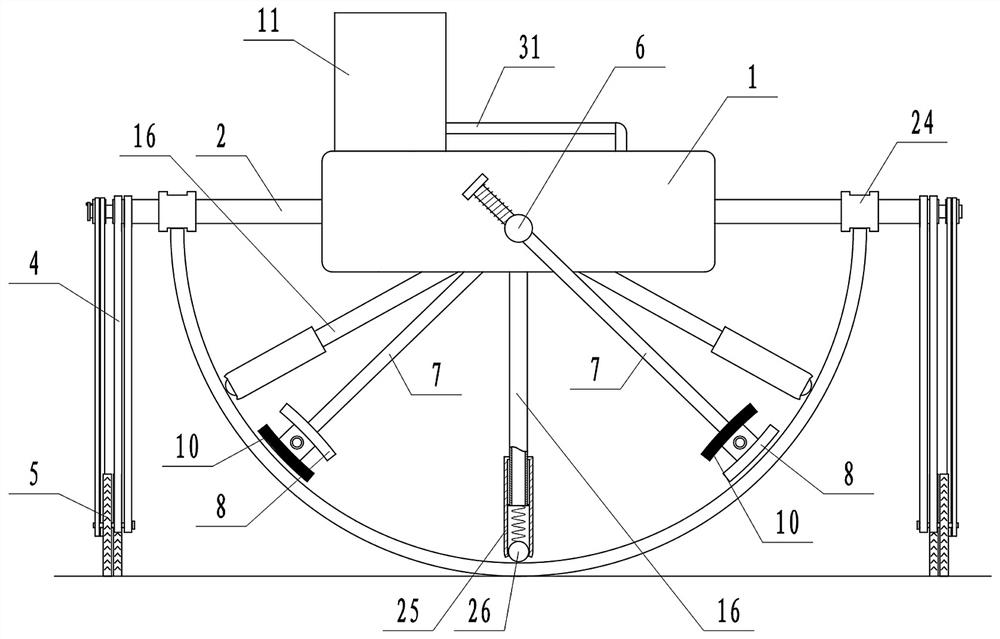

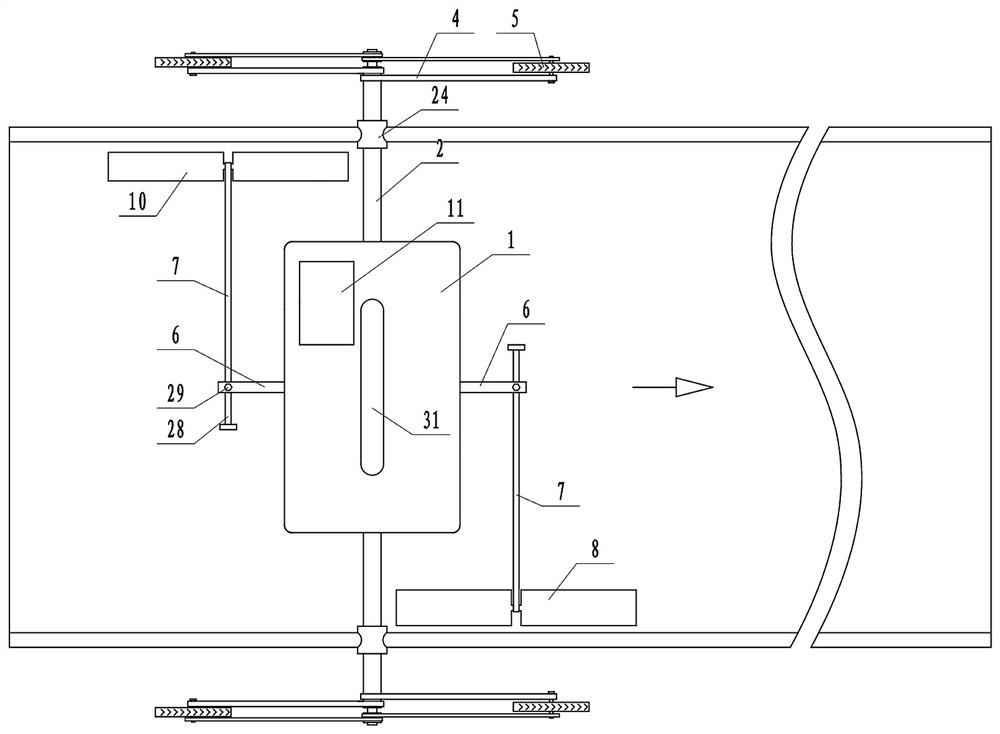

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Depend on Figure 1 to Figure 6 Provided, the present invention includes a housing 1 placed in the front and rear directions. There is a sleeve 2 in the front and rear directions on both sides of the housing 1. The sleeve 2 communicates with the inside of the housing 1. The sleeve 2 is inserted with a The rotating shaft 3 is equipped with two swingable connecting rods 4 at the front end and the rear end of the rotating shaft 3, and a wheel 5 is installed at the lower end of each connecting rod 4, and the rotation of multiple wheels 5 can drive the rotating shaft 3 to rotate;

[0017] The middle part of the housing 1 is inserted with two left and right horizontal shafts 6, the rotation of the rotating shaft 3 can drive the left and right two horizontal shafts 6 to rotate synchronously and reversely, and each horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com