A fast coating device for cast-in-place pile template

A technology of cast-in-place piles and templates, which is applied to the surface coating liquid device, coating, formwork treatment, etc., which can solve the problem of inconvenient application of release agent for semicircular templates, and achieve simplified operation and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

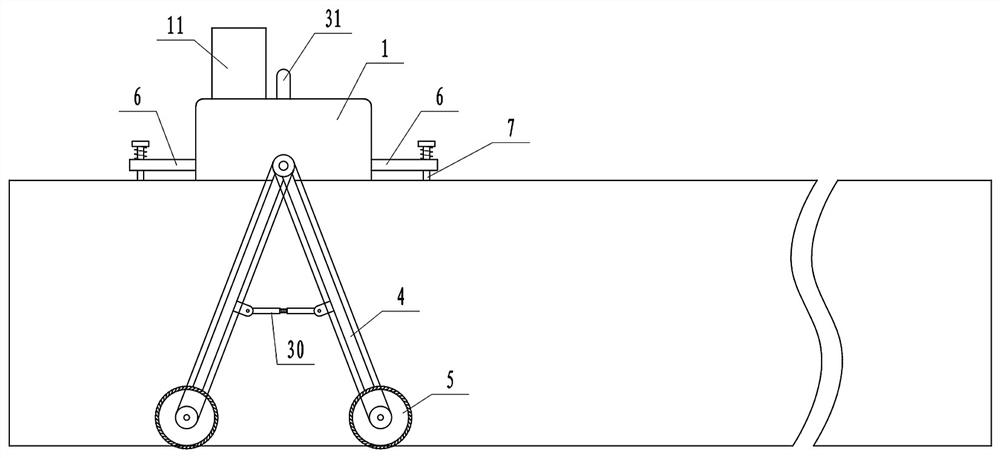

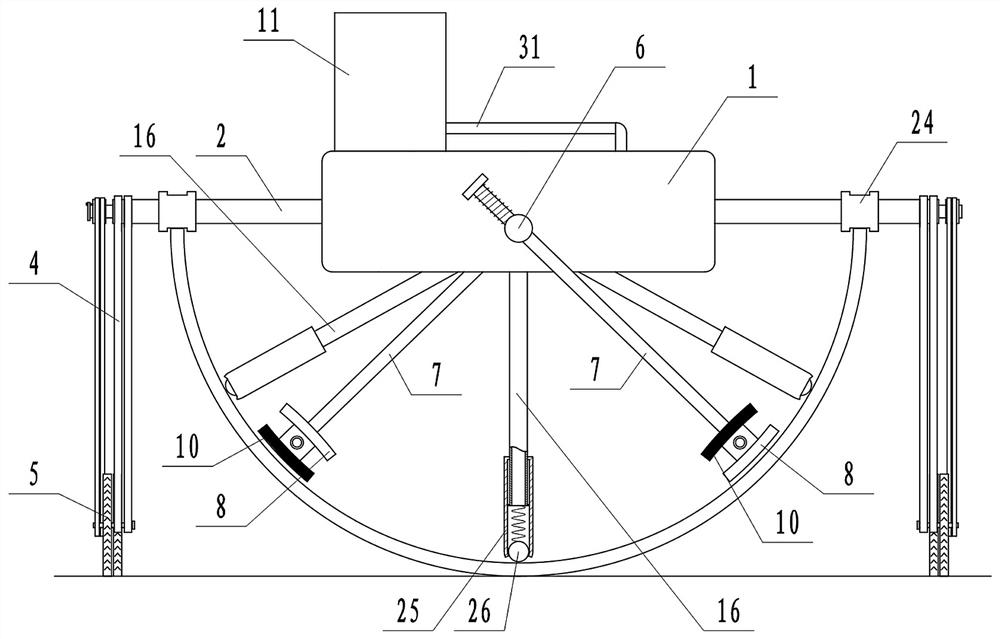

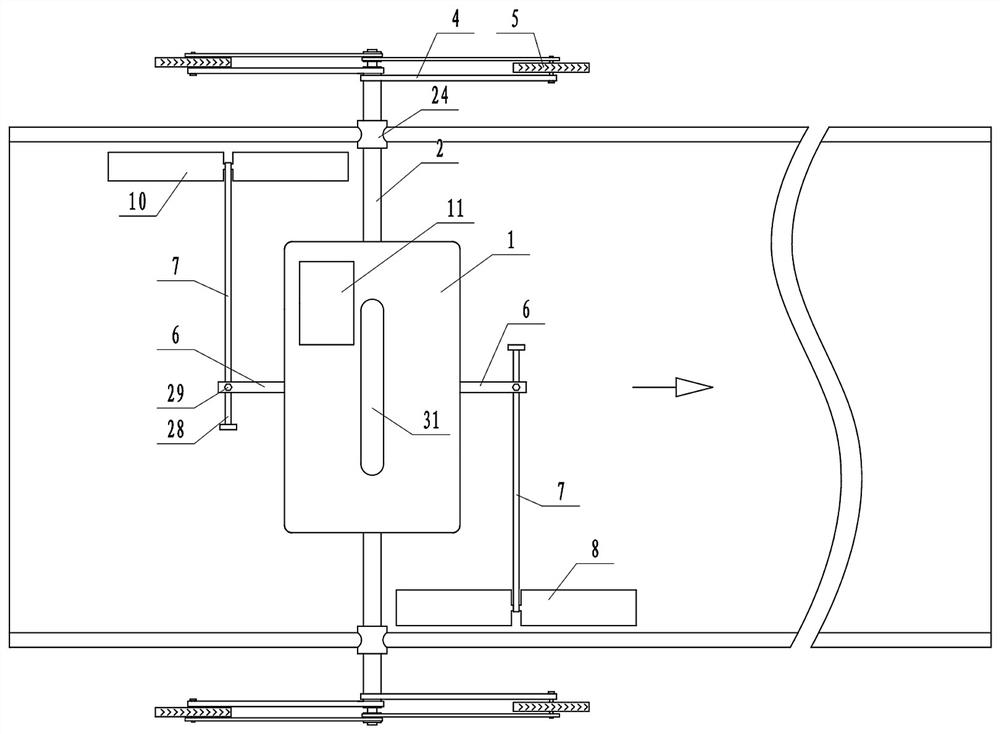

[0015] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0016] Depend on Figure 1 to Figure 6 Given, the present invention includes a housing 1 placed in a front-rear direction, a sleeve 2 in a front-rear direction on both sides of the housing 1, and the sleeve 2 communicates with the interior of the housing 1, and an energy source is inserted into the sleeve 2. The rotating shaft 3, the front end and the rear end of the rotating shaft 3 are equipped with two swingable connecting rods 4, and the lower end of each connecting rod 4 is equipped with a wheel 5, and the rotation of a plurality of wheels 5 can drive the rotating shaft 3 to rotate;

[0017] The middle of the casing 1 is fitted with two left and right horizontal shafts 6, the rotation of the rotating shaft 3 can drive the left and right horizontal shafts 6 to rotate in the opposite direction synchronously, and each horizontal sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com