Equipment for disc punching

A kind of equipment and disc technology, applied in the field of disc punching equipment, can solve the problem that it is difficult to accurately control plastic discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

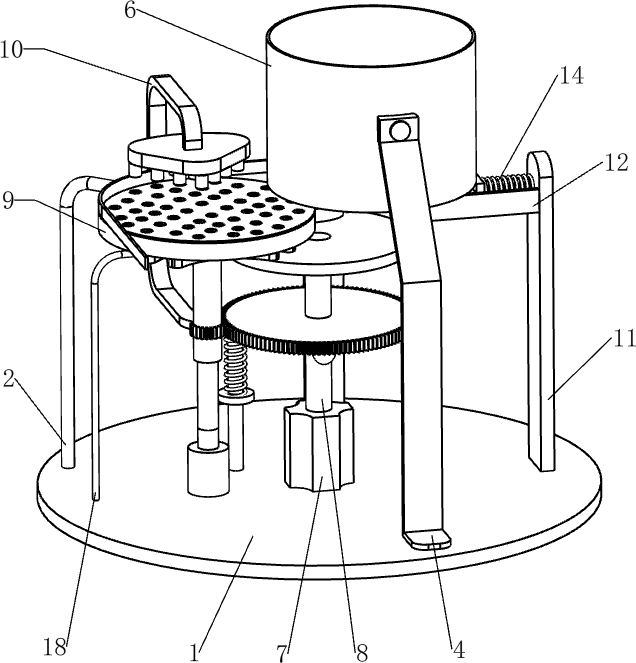

[0022] A device for punching holes in discs, such as Figure 1-6 As shown, it includes a base 1, a first support rod 2, an arc-shaped limit plate 3, a first support seat 4, a second support seat 5, a circular plate box 6, a servo motor 7, a first rotating shaft 8, and an intermittent rotation mechanism. 9. The punching mechanism 10, the fourth support rod 18 and the second bearing seat 19, the left side of the top of the base 1 is fixedly connected with the first support rod 2, the upper end of the first support rod 2 is provided with an arc-shaped limit plate 3, the base 1 The front side of the top is fixedly connected with the first support seat 4, and the rear side of the top of the base 1 is fixedly connected with the second support seat 5, and a circular plate box 6 is connected by bolts between the second support seat 5 and the top of the first support seat 4. 1. A servo motor 7 is installed in the middle of the top. The top of the output shaft of the servo motor 7 is pr...

Embodiment 2

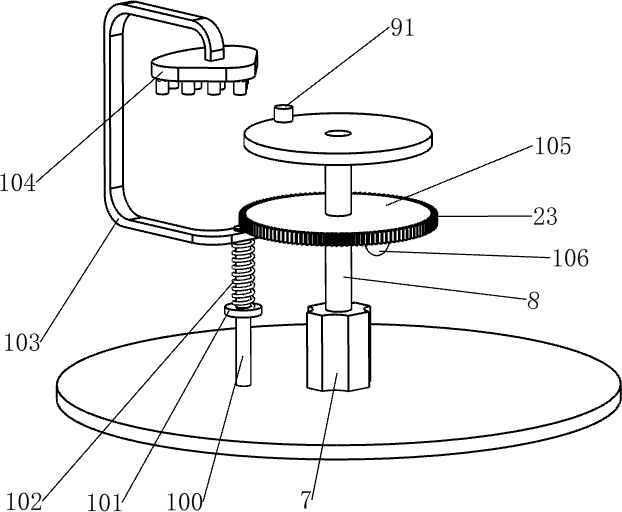

[0029] On the basis of Example 1, such as figure 1 and Figure 3-6 As shown, it also includes a support plate 11, a slide rail 12, a push plate 13, a second spring 14 and a second extrusion block 15, the right side of the top of the base 1 is fixedly connected with the support plate 11, and the left side of the support plate 11 is provided with Slide rail 12, sliding type is provided with push plate 13 in slide rail 12, is connected with second spring 14 between push plate 13 and support plate 11, is provided with the second extruding block 15 on the outer side of carrying plate 93, and the second extruding block 15 cooperates with push pedal 13.

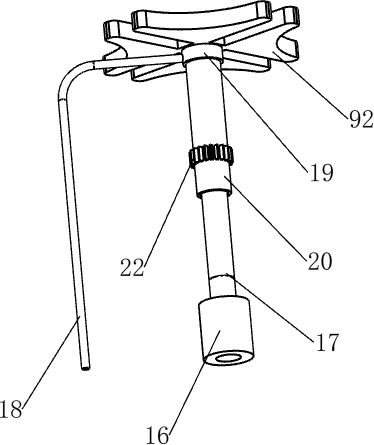

[0030] Also include first bearing seat 16, second rotating shaft 17, ring rotating shaft 20, driving lever 21, first gear 22 and second gear 23, first bearing seat 16 is installed on the left side of base 1 top, first bearing seat 16 The inner rotation type is provided with a second rotating shaft 17, the upper part of the second ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com