Raw material putting mechanism used for production and processing of medical intermediates

A technology of intermediates and raw materials, which is applied in the field of raw material feeding mechanism for the production and processing of pharmaceutical intermediates, which can solve the problems of agglomerated raw materials affecting processing and not having the function of crushing agglomerated raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

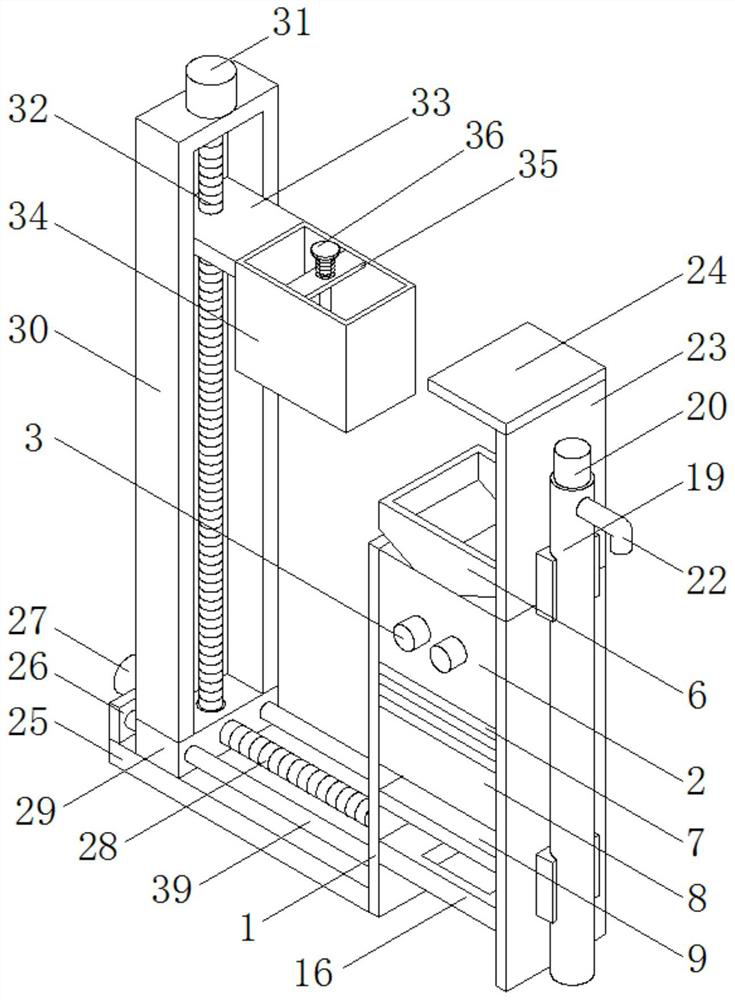

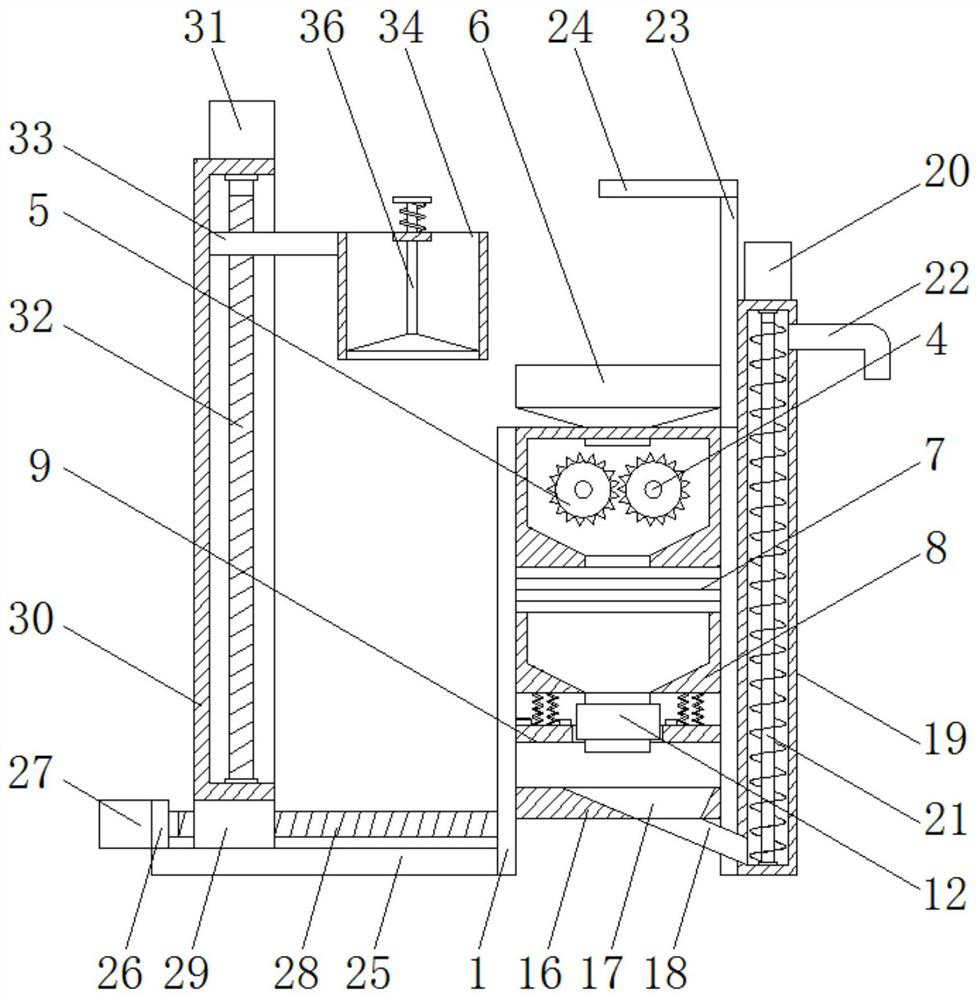

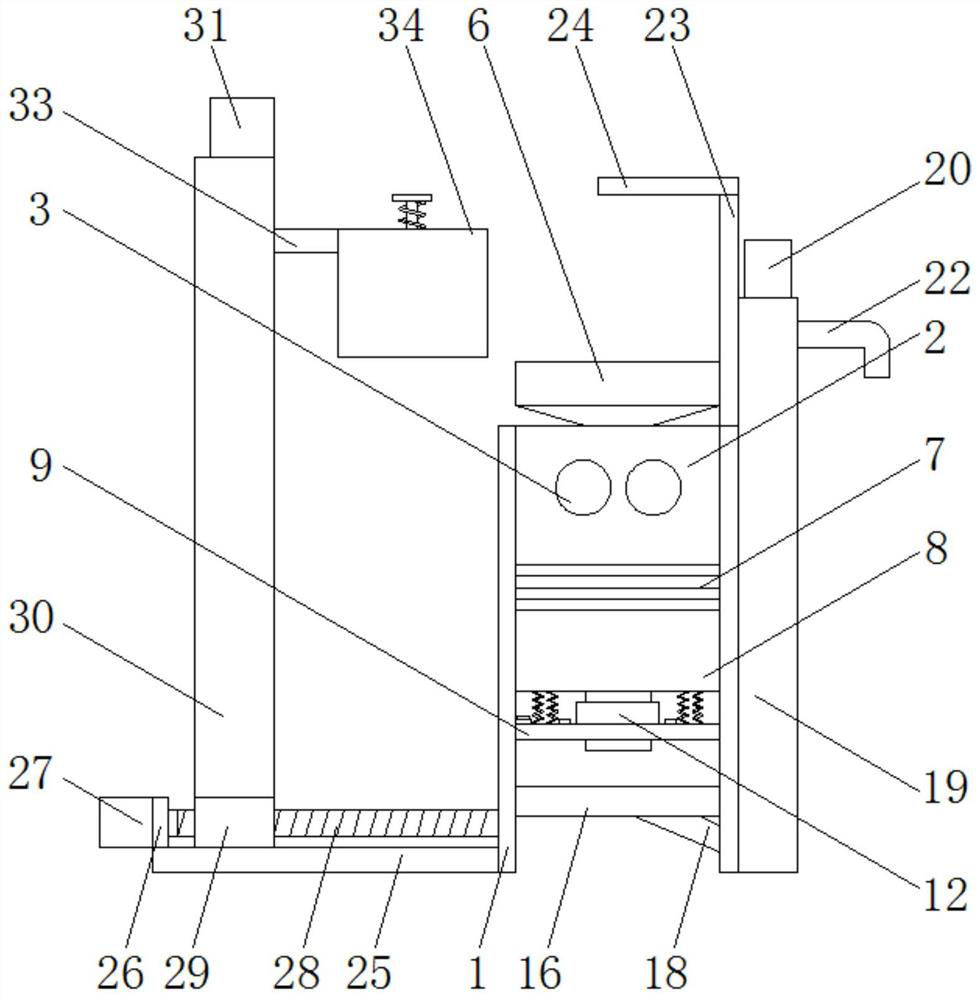

[0026] Example: such as Figure 1-5 As shown, a raw material feeding mechanism for the production and processing of pharmaceutical intermediates in the present invention includes a support plate 1, the number of support plates 1 is two, and a crushing assembly is arranged between the two support plates 1, and the crushing assembly consists of a crushing Chamber 2, two first motors 3, two rotating shafts 4, two crushing rollers 5, a hopper 6 and a discharge port 10, the bottom of the crushing chamber 2 is provided with a discharge assembly, the discharge assembly consists of a telescopic soft Tube 7, a collection box 8, a first horizontal plate 9, a discharge pipe 11, a control valve 12, two pads 13, a normally closed button switch 14 and several first springs 15;

[0027] One of the support plates 1 is provided with a feeding assembly, which is composed of a second horizontal plate 16, a groove 17, an inclined pipe 18, a delivery pipe 19, a second motor 20, a dragon 21 and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com