Automatic oil cake filling machine for oil pressing

An automatic filling and oil cake technology, which is applied in the direction of presses, manufacturing tools, fat oil/fat production, etc., can solve the problem of inability to add quantitatively, and achieve the effects of saving process steps, reducing labor intensity, and improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

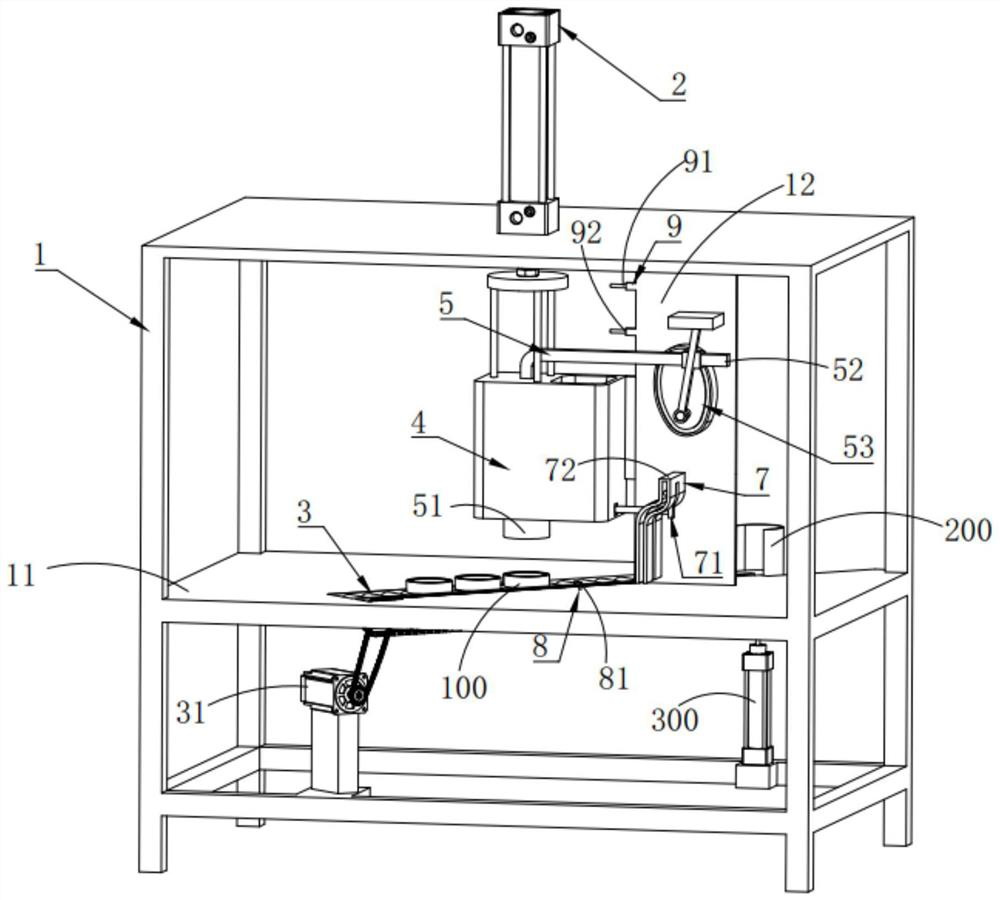

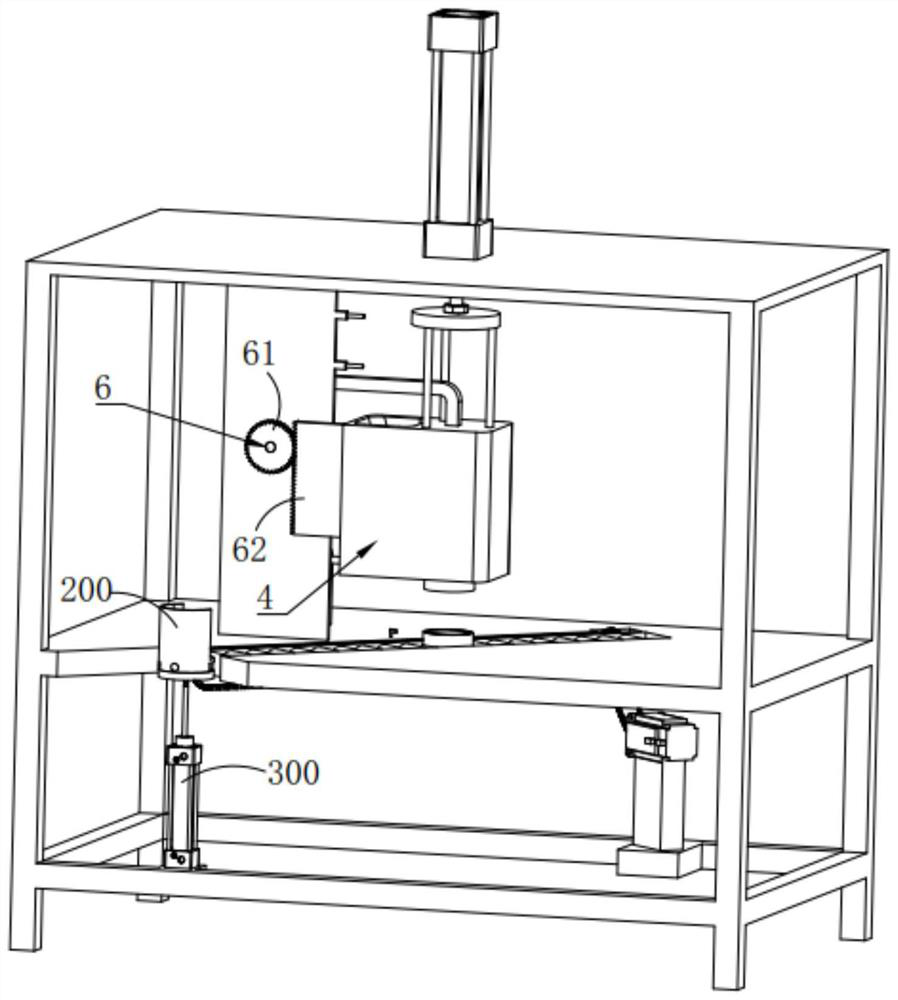

[0055] Such as Figure 1-7 As shown, an automatic oil cake filling machine for oil press processing includes a frame 1, a power unit 2 installed on the top of the frame 1, and a delivery unit 3 installed on the working surface 11 of the frame 1, and also includes:

[0056] Material box 4, described material box 4 is arranged on the below of described power unit 2 and is connected with the output end of power unit 2, the right half of described material box 4 is provided with the material bin 41 of top opening, material box 4 The left half of the bottom is provided with a guide cavity 42 with an open bottom, and the bottom of the guide cavity 42 is provided with a discharge port 43 communicated with the bottom of the silo 41.

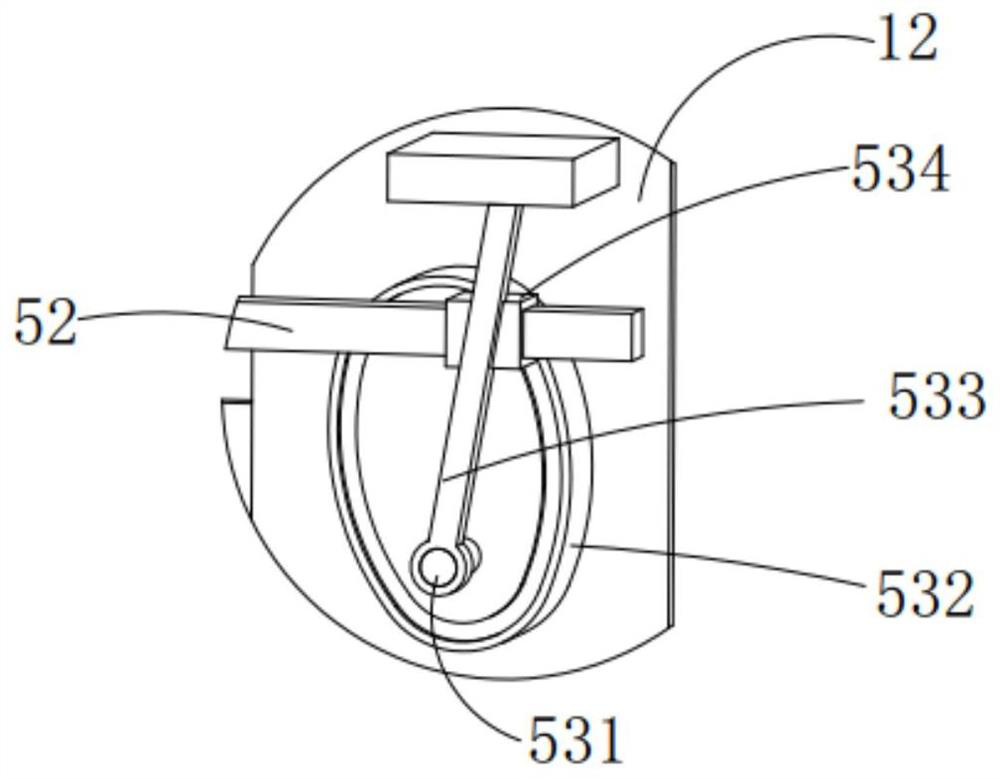

[0057] A primary feeding control unit 5, the primary feeding control unit 5 includes a pressure head 51, an L-shaped connecting rod 52 and a cam assembly 53;

[0058] The pressure head 51 is slidingly fitted in the guide cavity 42;

[0059] The L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com