Experimental metal/water reaction hydrogen production device and metal/water reaction hydrogen production collection method

An experimental device and water reaction technology, applied in the analysis of materials, instruments, etc., can solve the problems of large errors, time-consuming and laborious hydrogen production statistics, cumbersome hydrogen collection process, etc., to achieve high accuracy, overcome low precision, and high measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

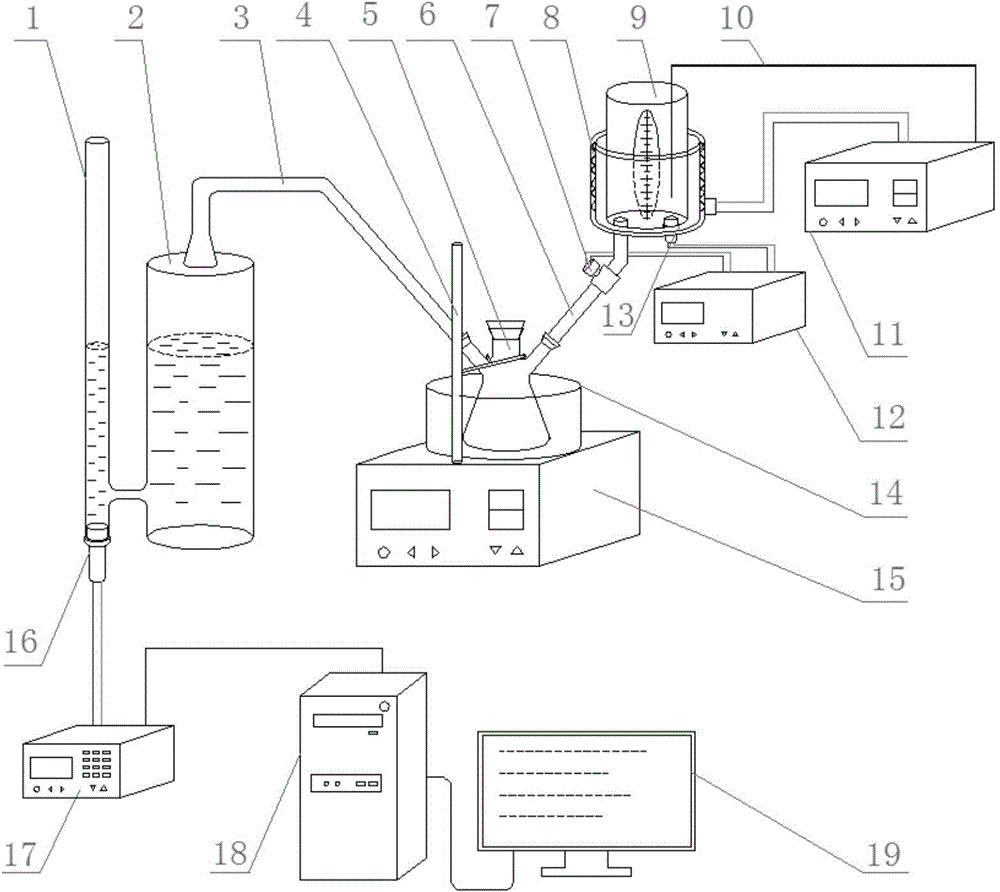

[0049] Such as figure 1 As shown, the metal / water reaction hydrogen production experimental device of this embodiment includes a solution storage mechanism, a reaction mechanism and a gas volume detection mechanism, the solution storage mechanism is connected to the reaction mechanism, and the reaction mechanism is connected to the gas volume detection mechanism, wherein: the solution storage The mechanism is used to store the reaction solution. The reaction mechanism is used to store the metal to be reacted and used as a reaction container. The gas volume detection mechanism is used to detect the amount of hydrogen generated by the reaction. Specifically, the reaction solution enters the reaction mechanism and reacts with the metal to generate hydrogen. The automatic real-time detection of gas production is realized in the gas volume detection mechanism.

[0050] The reaction mechanism comprises a fixed support 4, a three-necked conical flask 5, a constant temperature water b...

Embodiment 2

[0076] The metal / water reaction hydrogen production experimental device of this embodiment has the same basic structure as that of Embodiment 1, except that the wall thickness of the metering tube 1 is 1 mm, the inner diameter is 15 mm, and the height is 200 mm; the wall of the water storage tank 2 The thickness is 1mm, the inner diameter is 90mm, and the height is 100mm. In order to ensure that the reaction solution smoothly flows into the three-necked conical flask 5, the position of the solution storage tank 9 is 125mm higher than the position of the constant temperature water bath tank 14. The inner diameter of the heating box 8 is 100mm, and the height is 70mm. The bottom of the heating box 8 is perforated, and the aperture is 70mm; the solution storage box 9 is made of stainless steel, and the top is covered, and the two openings at the bottom are round holes with a diameter of 20mm; The solution storage tank 9 has a wall thickness of 1 mm, an inner diameter of 90 mm, an...

Embodiment 3

[0078] The metal / water reaction hydrogen production experimental device of this embodiment has the same basic structure as that of Embodiment 1, except that the wall thickness of the metering tube 1 is 2 mm, the inner diameter is 20 mm, and the height is 400 mm; the wall of the water storage tank 2 The thickness is 2mm, the inner diameter is 150mm, and the height is 300mm. In order to ensure that the reaction solution smoothly flows into the three-necked conical flask 5, the position of the solution storage tank 9 is 50mm higher than the position of the constant temperature water bath tank 14. The inner diameter of the heating box 8 is 50mm, and the height is 180mm. The bottom of the heating box 8 is perforated, and the aperture is 35mm; the solution storage box 9 is made of stainless steel, with a cover on the top, and two openings at the bottom are round holes with a diameter of 10mm; The solution storage tank 9 has a wall thickness of 2mm, an inner diameter of 40mm, and a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com