Feeding device for food packaging

A food packaging and material bag technology, which is applied in the field of food packaging feeding devices, can solve the problems of inconvenient screening of finished materials and powder materials, easy falling of materials, and inconvenient transportation of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

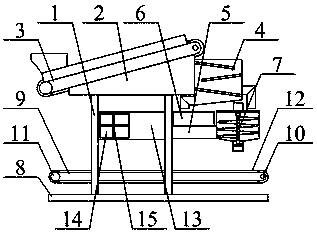

[0040] as attached figure 1 And attached image 3 shown

[0041]The invention provides a feeding device for food packaging, which includes a longitudinal fixed frame 1, an inclined fixed frame 2, an auxiliary lifting frame structure 3, a sorting and deriving frame structure 4, a horizontal cushion frame 5, a powder storage hopper 6, and quantitatively deriving materials Frame structure 7, fixed bottom plate 8, material bag transport frame 9, material bag conveying roller 10, conveying motor 11, material bag conveying belt 12, console 13, tool storage frame 14 and cross-shaped partition 15, the inclined The fixed frame 2 bolts are installed on the upper side of the longitudinal fixed frame 1; the auxiliary lifting frame structure 3 is installed on the upper side of the inclined fixed frame 2; The bolts of the horizontal pad 5 are installed in the middle of the longitudinal fixed frame 1; the powder storage hopper 6 is placed on the upper right side of the horizontal pad 5; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com