Electric iron tower main material reinforcing device

A reinforcement device and a technology for power towers, applied in towers, building maintenance, building types, etc., can solve problems such as no seismic buffer effect, affecting construction efficiency, poor environmental adaptability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

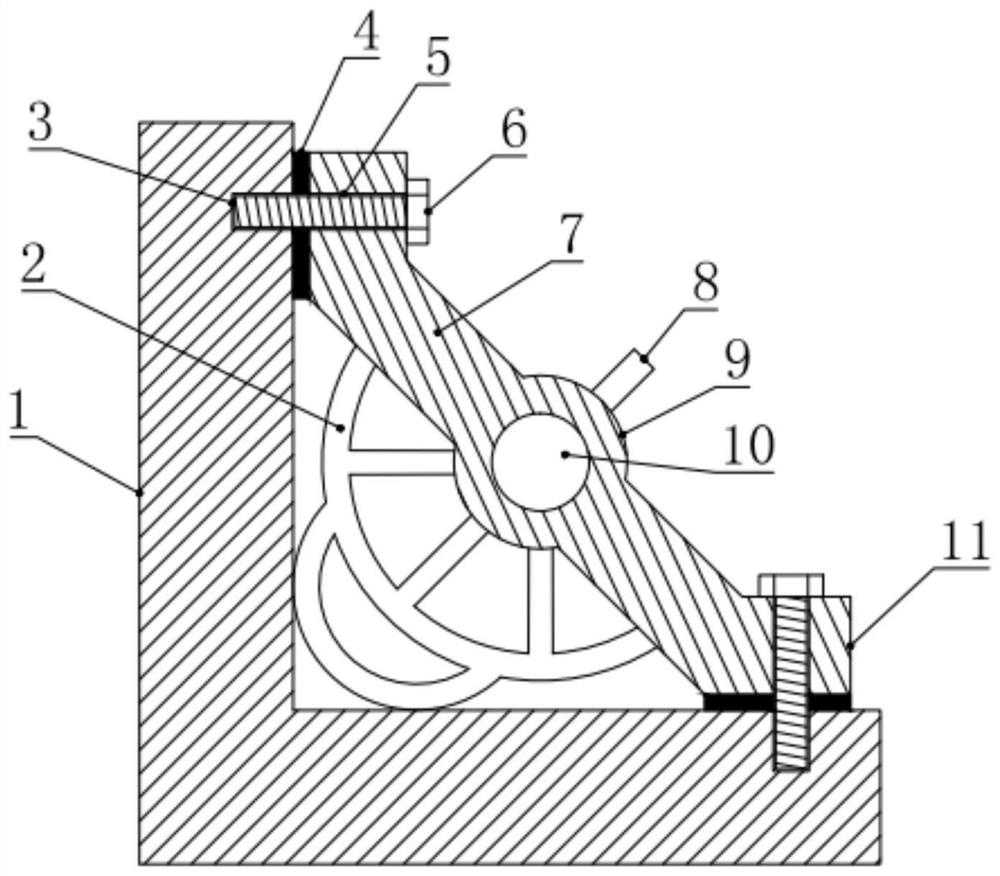

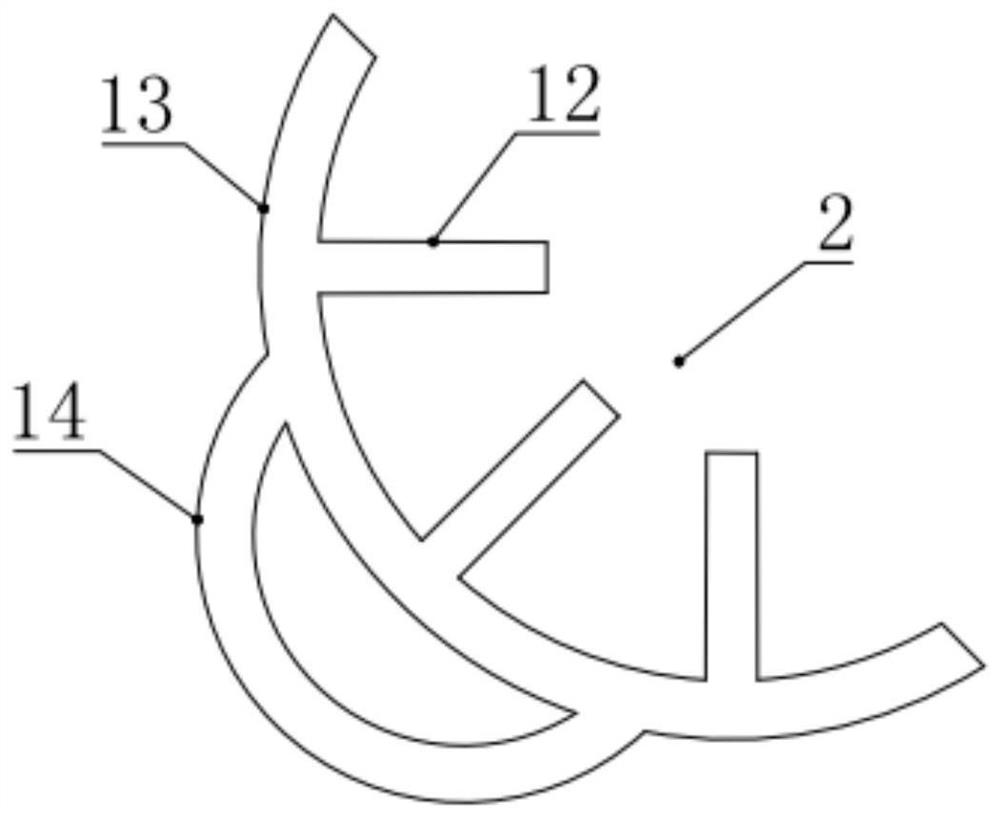

[0025] see figure 1 , in an embodiment of the present invention, a main material reinforcement device for an electric power tower includes a main material plate 1 with an L-shaped structure, and a plurality of reinforcing sloping plates 7 are installed and fixed on the inner side of the main material plate 1, and the reinforcing sloping plates 7 The side close to the main material plate 1 is also fixed with a plurality of elastic support components 2, and the elastic support components 2 elastically abut against the two branches of the main material plate 1, and the two adjacent reinforcement slant plates 7 The turnbuckle bolts 15 are also supported and fixed between them, and the two ends of the turnbuckle bolts 15 are correspondingly connected and fixed with the two reinforced sloping plates 7 .

[0026] In the embodiment of the present invention, by fixing the reinforcement slant plate 7 on the inner side of the main material plate 1, the reinforcement slant plate 7 can for...

Embodiment 2

[0028] see Figure 1-4 , the difference between this embodiment and embodiment 1 is:

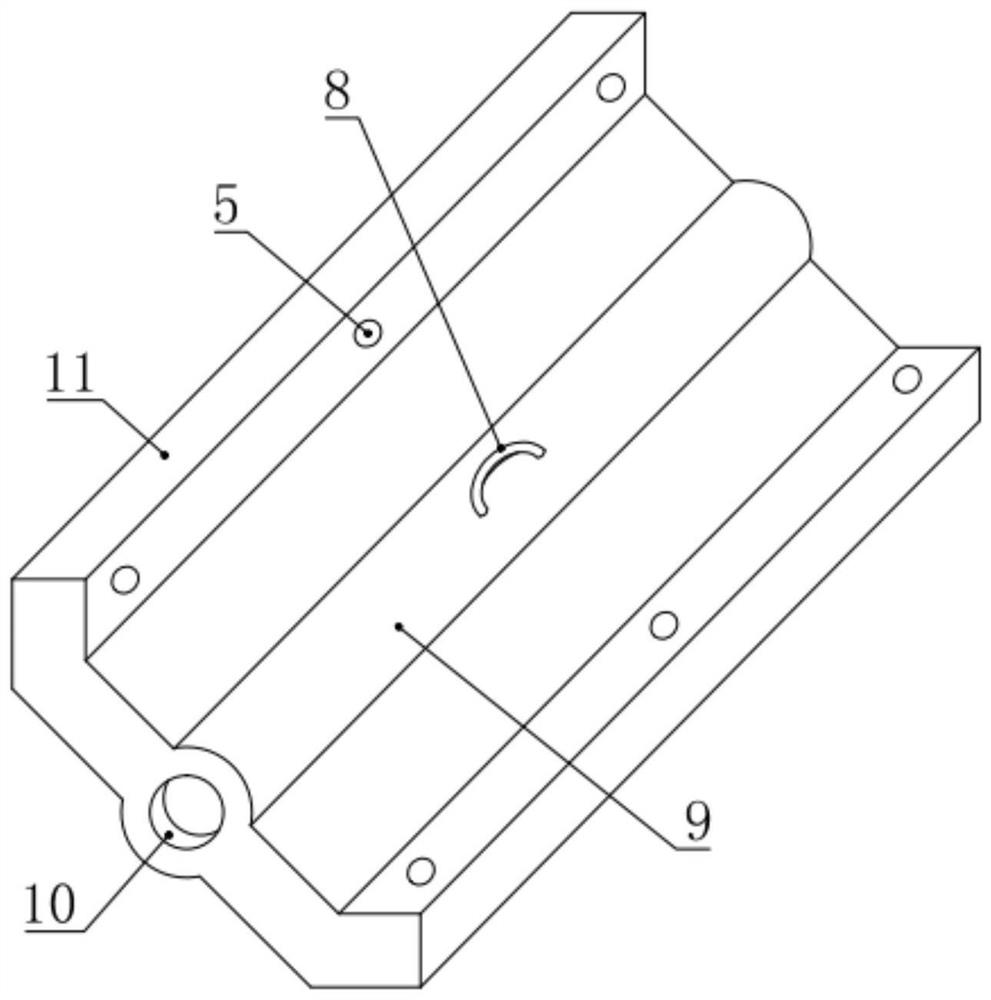

[0029] In this example, if figure 1 and 2 As shown, the reinforcement slant plate 7 is evenly distributed on the inner side of the main material plate 1, the two branches of the reinforcement slant plate 7 and the main material plate 1 are set at an angle of 45°, and the two ends of the reinforcement slant plate 7 are provided with The two branches of the main material plate 1 are parallel extensions 11, a gasket 4 is also provided between the extensions 11 and the main material plate 1, and a plurality of second screw holes 5 are opened on the extensions 11, which are in line with the described The main material plate 1 corresponding to the second screw hole 5 is provided with a first screw hole 3, and the fixing bolt 6 passes through the second screw hole 5 and the gasket 4 and is fixed on the first screw hole 3, which realizes the reinforcement The inclined plate 7 is connected and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com