I-shaped steel support system

A technology of I-beams and pillars, which is applied to pillars/brackets, mining equipment, earthwork drilling and mining, etc. It can solve problems such as reinforcement of hidden danger points, slow construction progress, high maintenance costs, etc., and achieve enhanced support reinforcement effect and support reinforcement effect Good, good effect of support and reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

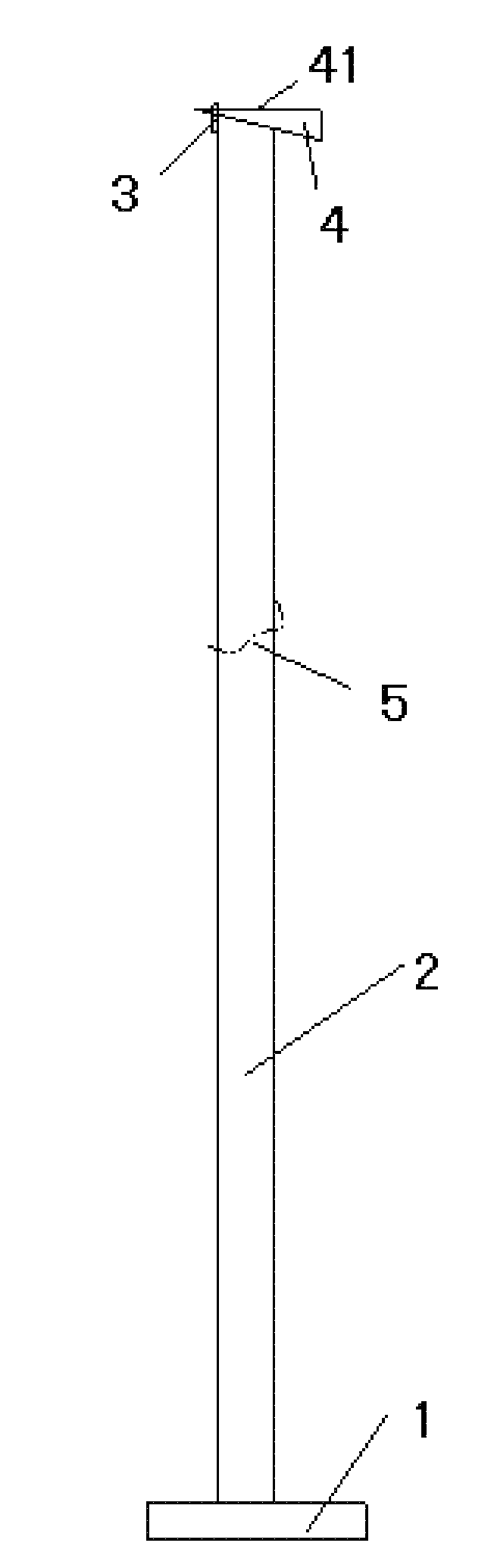

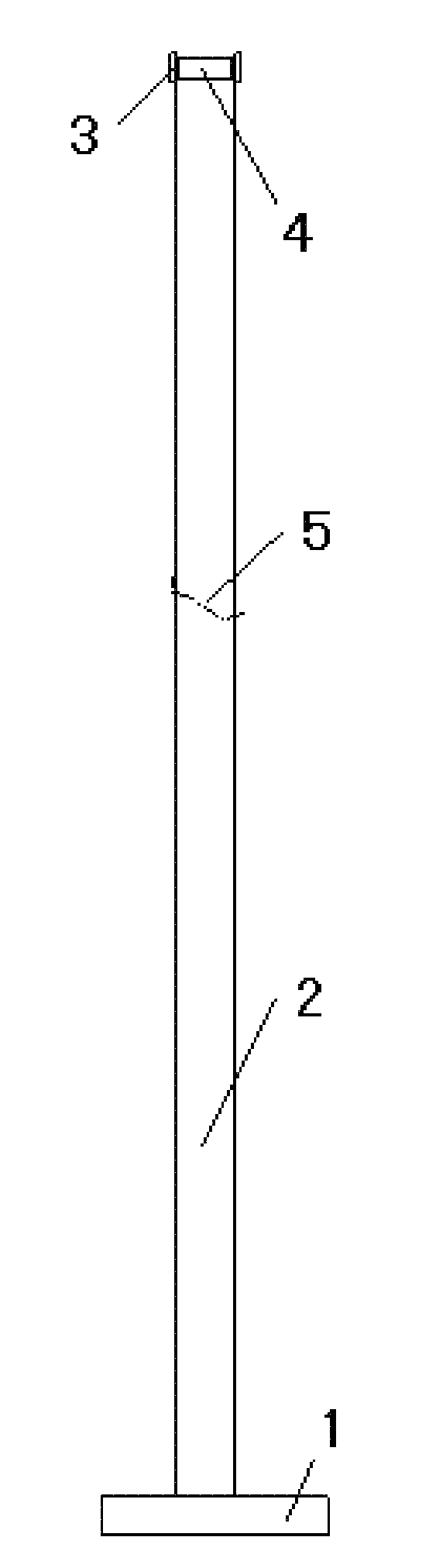

[0012] Such as figure 1 , figure 2 As shown, the present invention includes some iron shoes 1, I-beam 2, beam claw 3, cork 4 and anti-falling rope 5.

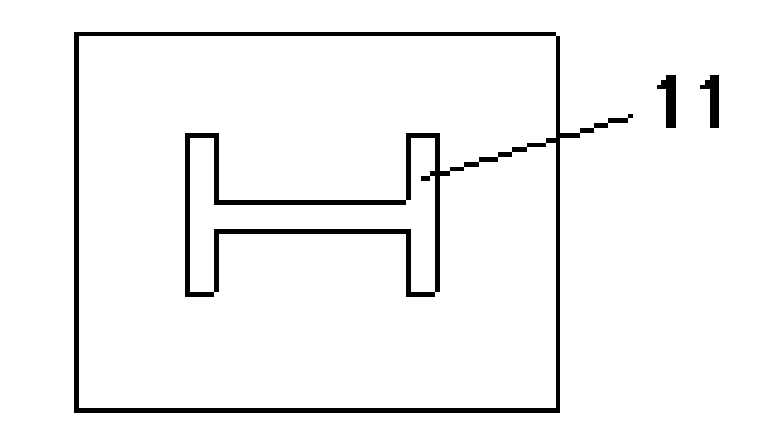

[0013] Such as image 3 As shown, the iron shoe 1 of the present invention can be a rectangular structure, and can also be a circular, hexagonal or other shaped structure. An I-shaped groove 11 is arranged on the top surface of the iron shoe 1 . Iron shoe 1 is placed on the roadway bottom plate (not shown in the figure), and it is used for increasing the contact area of I-beam 2 and roadway bottom plate, prevents I-beam 2 from drilling on the roadway bottom plate.

[0014] Such as figure 1 , image 3 As shown, the I-beam 2 of the present invention is an I-shaped columnar structure made of steel materials. The bottom of the I-beam 2 is inserted into the groove 11 of the iron shoe 1 to realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com