Petroleum extraction well mouth return pressure control device

A control device, a technology for oil extraction, which is applied in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve problems such as increasing work difficulty, reducing practicability, etc. The effect of extrusion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

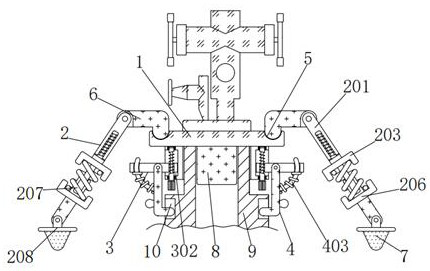

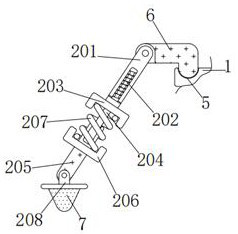

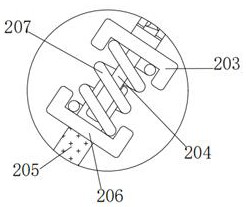

[0035] A wellhead back pressure control device for oil production, including a back pressure control device 1, the model of which is JKQ65-35, a circular groove 5 is processed under the back pressure control device 1, and the left and right sides of the inner wall of the circular groove 5 The brackets 6 are slidingly clamped, the circular groove 5 is in the shape of a ring, and the support mechanism 2 is installed on the front and outside of the two brackets 6. The support mechanism 2 includes a first inclined plate 201, a first threaded rod 202, and a first concave plate. 203, straight bar 204, the second slant plate 205, the second concave plate 206, the first spring 207 and the convex plate 208, the top of the first slant plate 201 is connected to the front left side of the support 6 by rotation, the first slant plate 201 is subjected to The force is rotated through the pin shaft on the left side of the front of the bracket 6, the inner wall of the first slant plate 201 is t...

Embodiment 2

[0037] As an option, see figure 1 , 4 , 5 and 6, oil production wellhead back pressure control device, the bottoms of the two second sloping plates 205 are fixedly connected with curved blocks 7 respectively, and the two curved blocks 7 are formed in a triangular shape, which is convenient for insertion into the ground, and the back pressure control device 1 The bottom of the thick tube 8 is connected with a thick tube 8, the outer wall of the thick tube 8 is plugged with a wellhead 9, the left and right sides of the wellhead 9 are processed with chute 10, the top of the wellhead 9 is tightly connected to the bottom of the back pressure control device 1, and the back pressure A control mechanism 3 is installed on the outside of the bottom of the control device 1. The control mechanism 3 includes a shell 301, a groove 302, a second threaded rod 303, a straight plate 304 and a handle 305. The top of the shell 301 is connected to the bottom outside of the back pressure control de...

Embodiment 3

[0040]As an option, see figure 1 , 4 , 5 and 6, oil production wellhead back pressure control device, the front of two straight plates 304 is equipped with a fixed mechanism 4, the fixed mechanism 4 includes a curved plate 401, a handle 402, a curved rod 403 and a second spring 404, two curved plates The tops of 401 are respectively connected to the front of the straight plate 304 for rotation, and the bent plate 401 is forced to rotate through the pin shaft on the front of the straight plate 304. The outer and lower sides of the two bent plates 401 are respectively fixed with the inner side of the handle 402, and the handle 402 is convenient for pulling the bent plate 401 rotates, the outer sides of the two curved plates 401 are fixedly connected to the inner sides of the curved rods 403 respectively, and the tops of the outer walls of the two curved rods 403 are respectively matched with the front outer sides of the straight plate 304, and the curved rods 403 are stressed up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com