Throttling device of lubricating oil system and using method thereof

A technology of throttling device and lubricating oil, which is used in quantitative devices, lubricating parts, engine lubrication, etc., can solve the problems of endangering the safety of steam turbine operation, improper speed of operation methods, and increase of differential pressure of filter screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0029] Example.

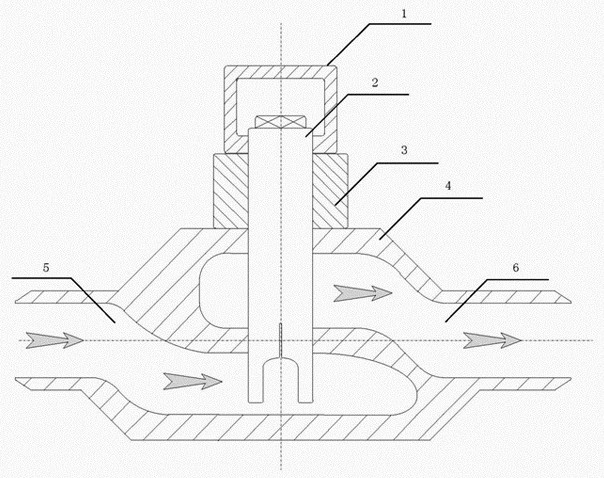

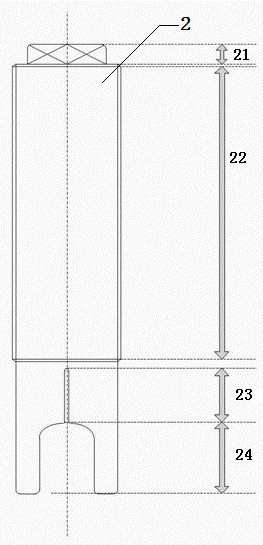

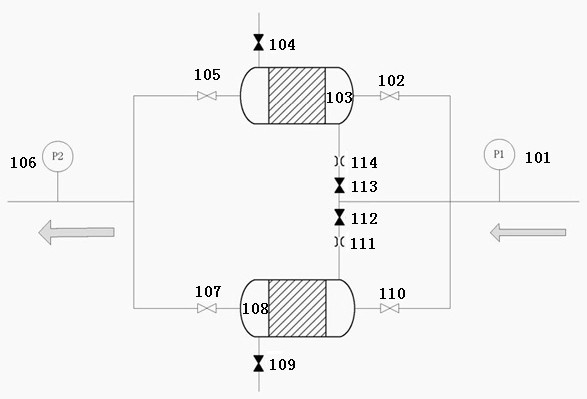

[0030] see Figure 1 to Figure 3 , the throttling device of the lubricating oil system in this embodiment includes a cap 1, a valve core 2, a tight nut 3 and a valve seat 4; figure 1 Lubricating oil inlet 5 and lubricating oil outlet 6 are also marked inside, the throttling device of the lubricating oil system is installed between the oil filling valve of the lubricating oil filtering device and the lubricating oil filtering device; the filter element is in the middle of the valve seat 4, and the tight nut 3 is on the upper part of the valve seat 4 , and outside the spool 2, the cap 1 is on the upper part of the tight nut 3, and outside the adjustable spool 2;

[0031] The spool 2 of this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com