Fuel combined injection structure based on wedge-shaped body

A wedge-shaped body and fuel technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as difficult thermal protection and large total pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

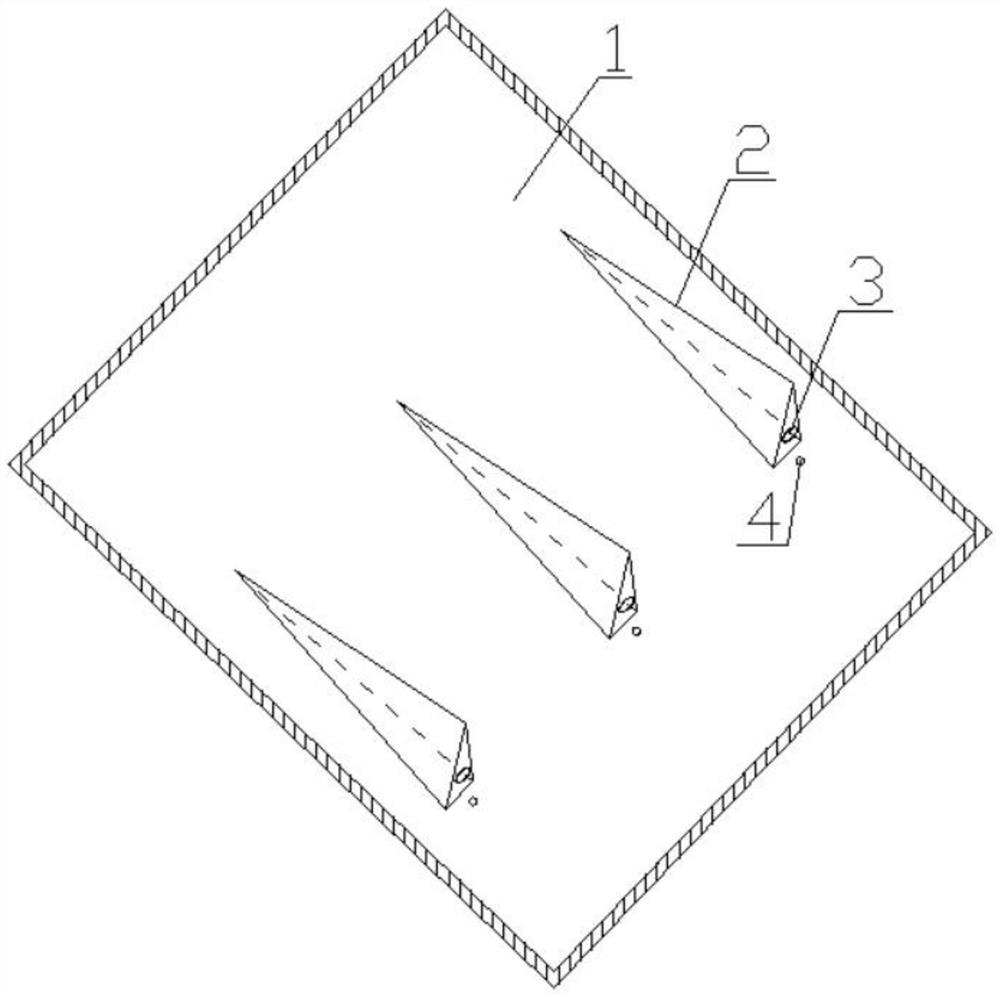

[0020] as attached figure 1 Shown: a fuel combination injection structure based on wedges, including wedges 2, wedges 2 and the combustion chamber are made by integral molding technology, and multiple wedges 2 are equally spaced in the combustion chamber of the scramjet On the wall 1, a plurality of wedges 2 are arranged on the width direction of the combustion chamber wall 1. The cross-sectional shape of the wedges 2 is triangular, and the side with a small cross-sectional area on the wedges 2 faces the upstream of the scramjet. The leeward side of the body 2 has an oval nozzle hole 3, and the oval nozzle hole 3 on the leeward side of the wedge body 2 can improve the distribution of fuel in the width direction of the combustion chamber and increase the contact area between the fuel jet and the supersonic incoming flow, thereby promoting The diffusion and mixing of fuel in the width direction of the combustion chamber, and the momentum component of the fuel jet in the oval noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com