Take-up pipe with convertible form

One form and one technology, applied in the field of take-up tubes, can solve problems such as affecting the aesthetics, random swing of the take-up tubes, and thread jamming, so as to achieve simple and convenient installation and disassembly, avoid accidental damage, and reduce the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

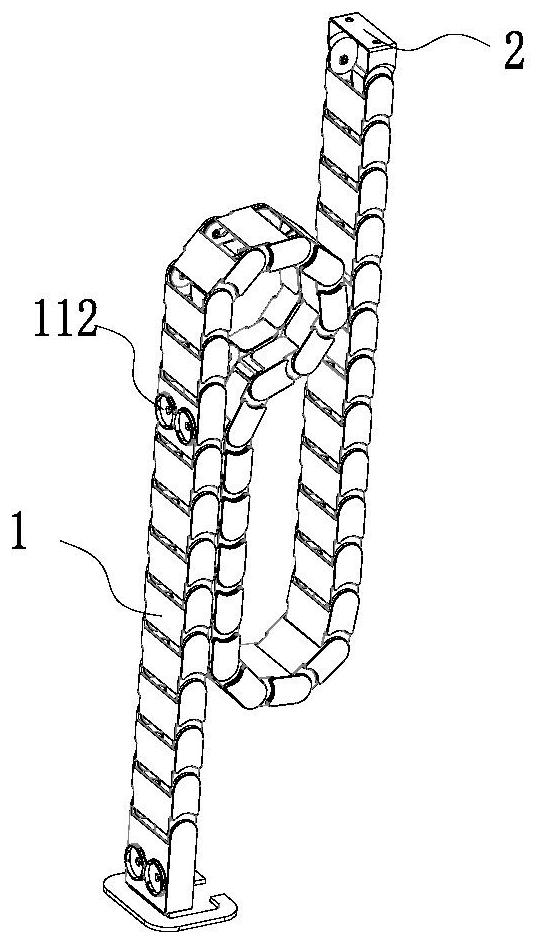

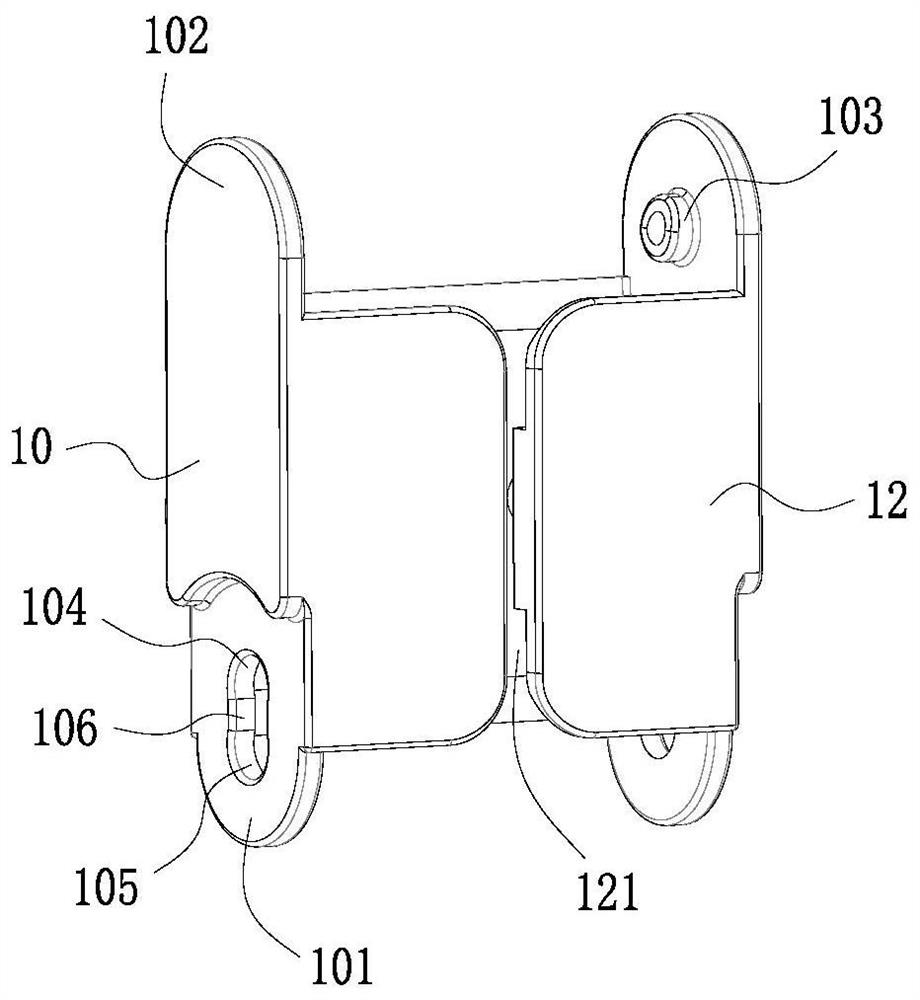

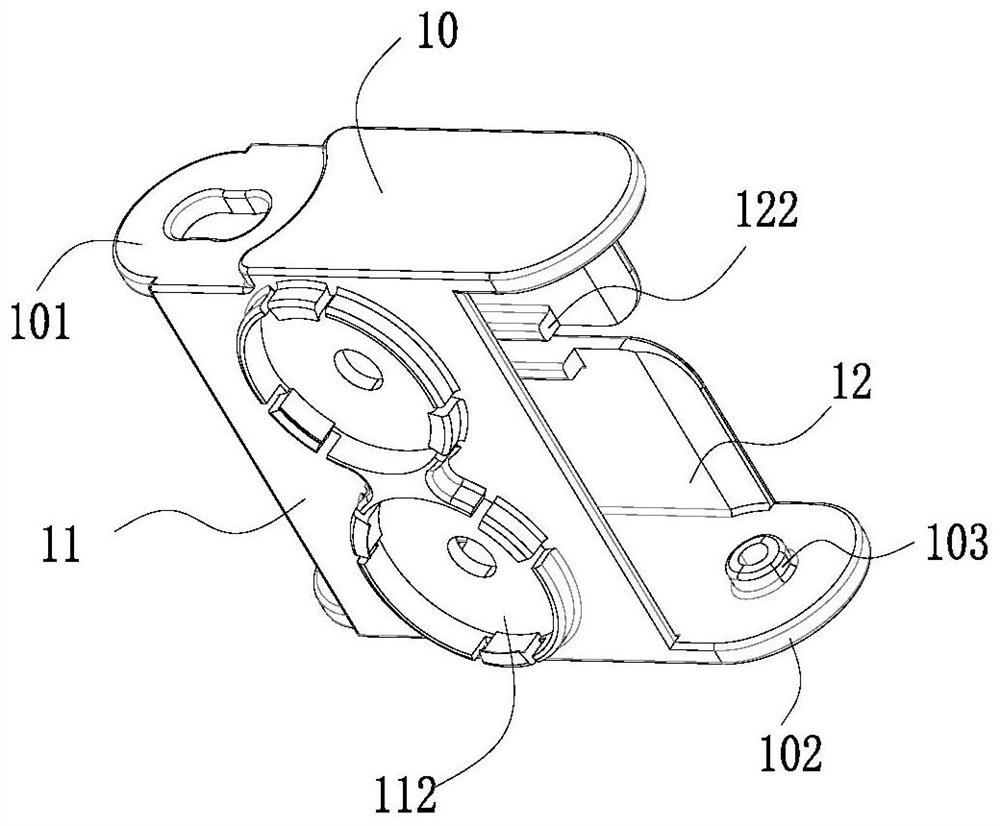

[0029] Such as Figure 1 to Figure 6 As shown, this embodiment shows a convertible form of take-up tube, including more than two single-section buckles 1 connected together, the single-section buckle 1 includes a connecting end 102 and a connected end 101, two When the single-section buckle 1 is in the connected state, the connecting end 102 of one single-section buckle 1 is connected to the connected end 101 of the other single-section buckle 1, and the two single-section buckles 1 are respectively deflected with the connection point as the center of the circle, so An adjustment component is provided at the joint of the two single-section buckles 1, and the two adjacent single-section buckles 1 include a locked state and an active state under the action of the adjustment component. In the locked state, the two single-section buckles 1 maintain Straight and active, the two single-section buckles 1 are relatively deflected.

[0030] In this embodiment, the connecting end 102 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com