Method for calibrating a position of a matrix headlamp of a motor vehicle, control device, and motor vehicle

A control device, technology for motor vehicles, used in testing the alignment of car headlights, headlights, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

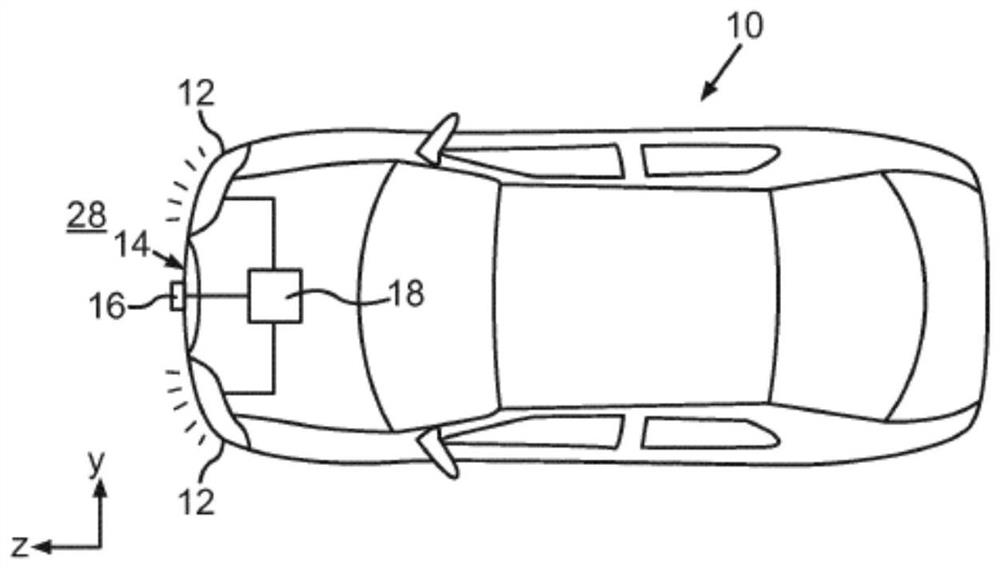

[0041] figure 1 A schematic illustration of a motor vehicle 10 according to an exemplary embodiment of the invention is shown, which has two array headlights 12 designed as headlights, a front camera 16 arranged on the vehicle front 14 and a control device 18 . In this case, the control device 18 is coupled not only to the camera 16 but also to the corresponding headlight array 12 and is designed to adjust the position of the headlight array 12 relative to the camera 16 . In this case, the adjustment of the right and left array headlights 12 takes place in the same manner and is therefore explained below only with reference to the individual array headlights 12 .

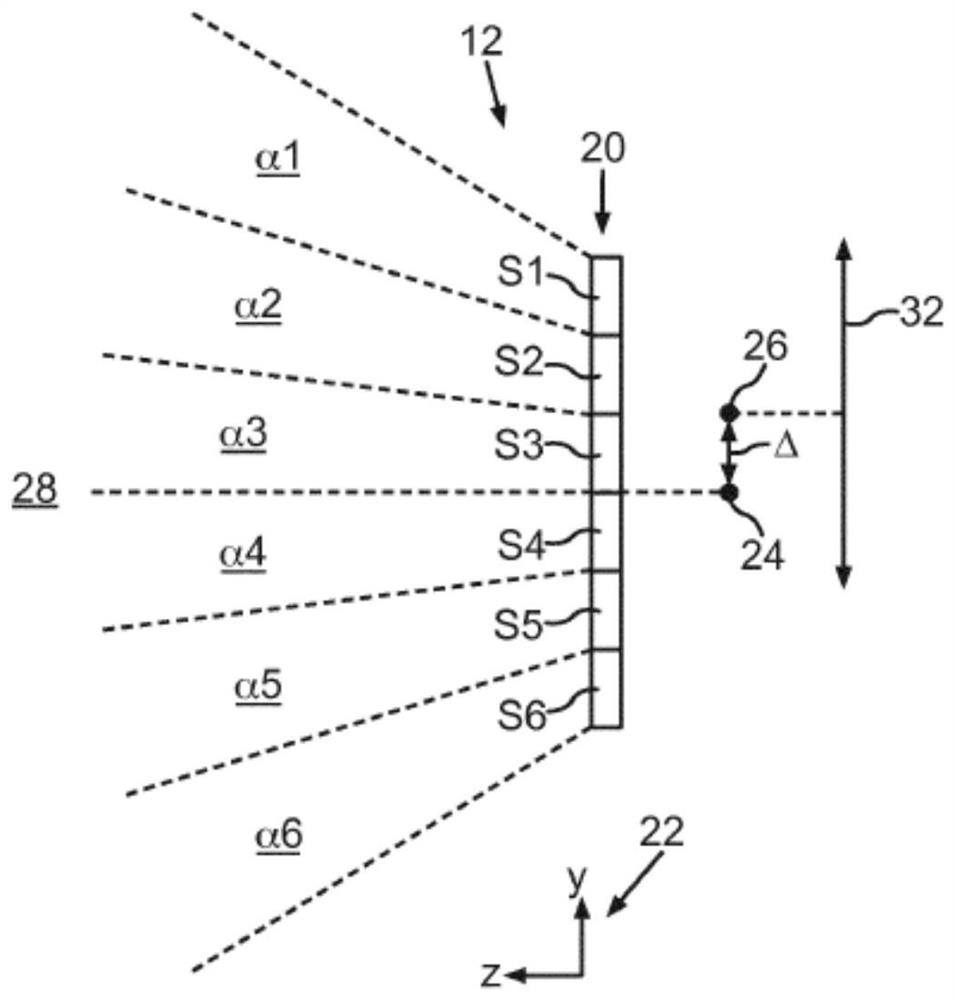

[0042] Such an array headlamp 12 is schematically shown again in detail in figure 2 shown in . The array headlight 12 here has, for example, six segments S1 , S2 , S3 , S4 , S5 , S6 arranged in a row 20 extending along the y-axis of the illustrated motor vehicle coordinate system 22 , Wherein, the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com