Dot-matrix inkjet coding machine vision automatic detection system for steel plate production line

A machine vision and automatic detection technology, applied in the fields of instruments, measuring devices, scientific instruments, etc., can solve the problems of difficult coding detection and identification, difficult to meet, and many missed detections and false detections, so as to increase traceability and improve production. The effect of rhythm and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

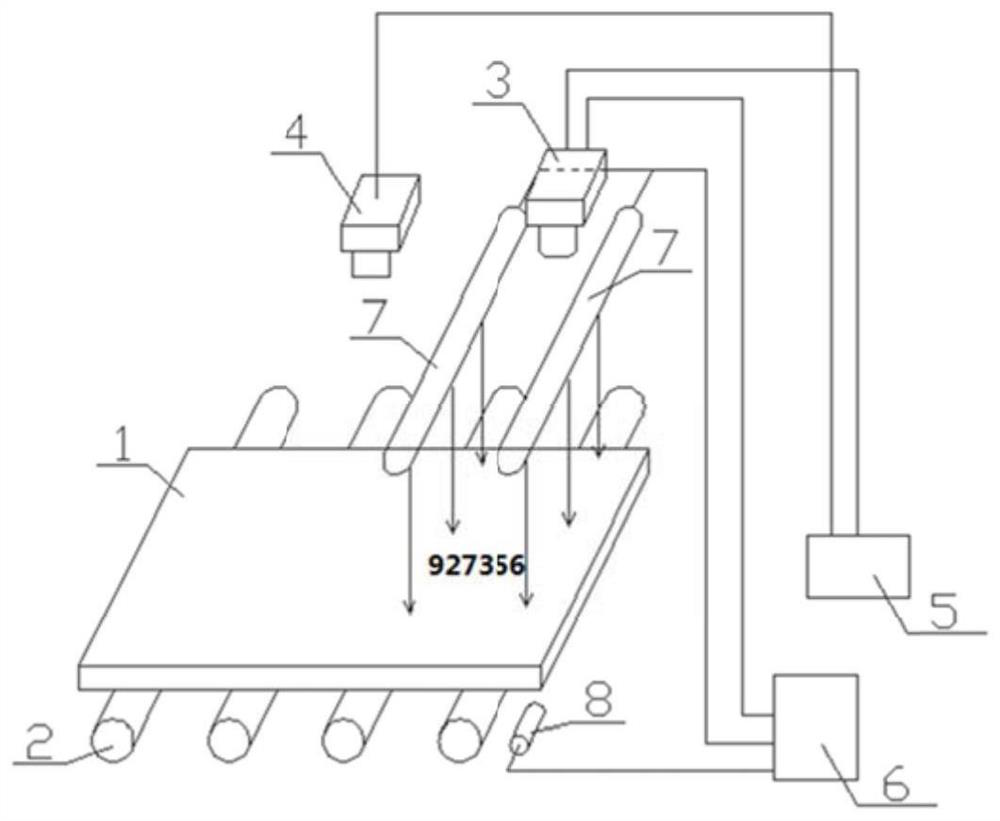

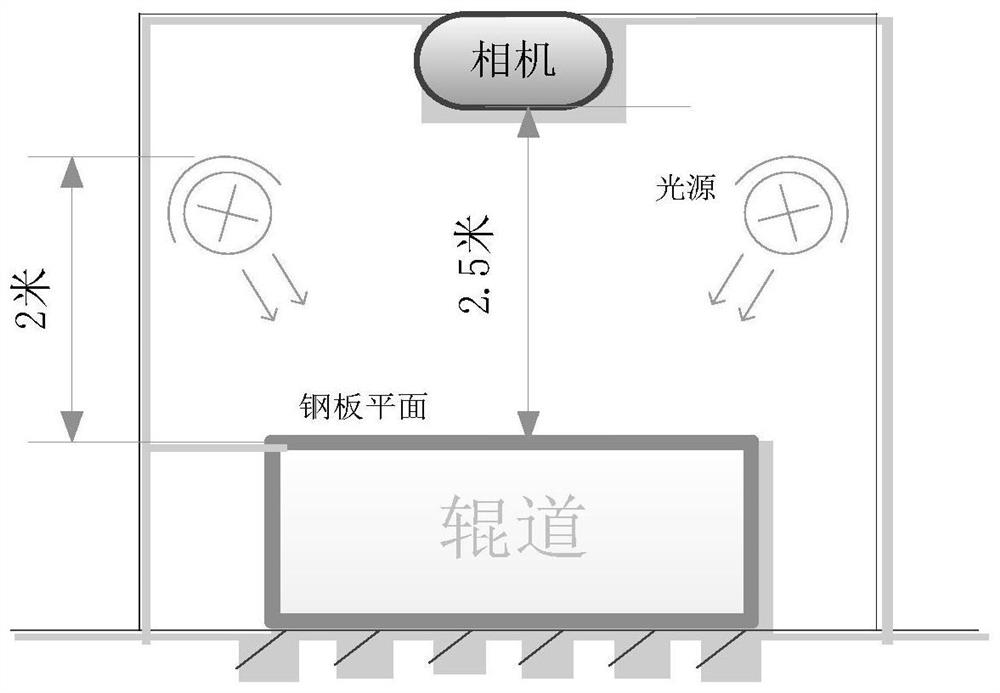

[0036] Such as figure 1 As shown, the steel plate production line of the present invention includes: a roller 2, an infrared sensor 8, a controller 6, an image acquisition unit 3, a speedy unit 4, an Ethernet, an image processing terminal 5. Among them: The image acquisition unit 3 includes an industrial camera, a cooling box, a dustproof and waterproof. The speed unit 4 includes a low resolution surface array camera, a structural light. The image processing terminal 5 includes: a character positioning module, a character division module, a character identification module.

[0037] In a specific embodiment, the infrared sensor 8 is mounted to the roller 2, and the information of the steel sheet 1 is detected, the infrared sensor 8 and the image acquisition unit 3 are connected to the controller 6.

[0038] In a specific embodiment, the industrial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com