Forest fire barrier

A technology of forest fire prevention and isolation belt, applied in the field of forest fire prevention, can solve the problems of difficulty in concrete grooves and isolation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

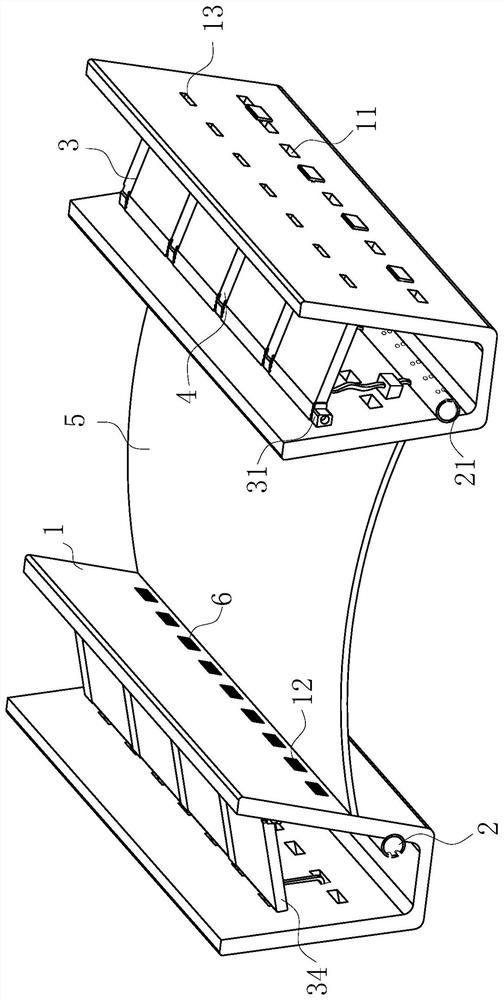

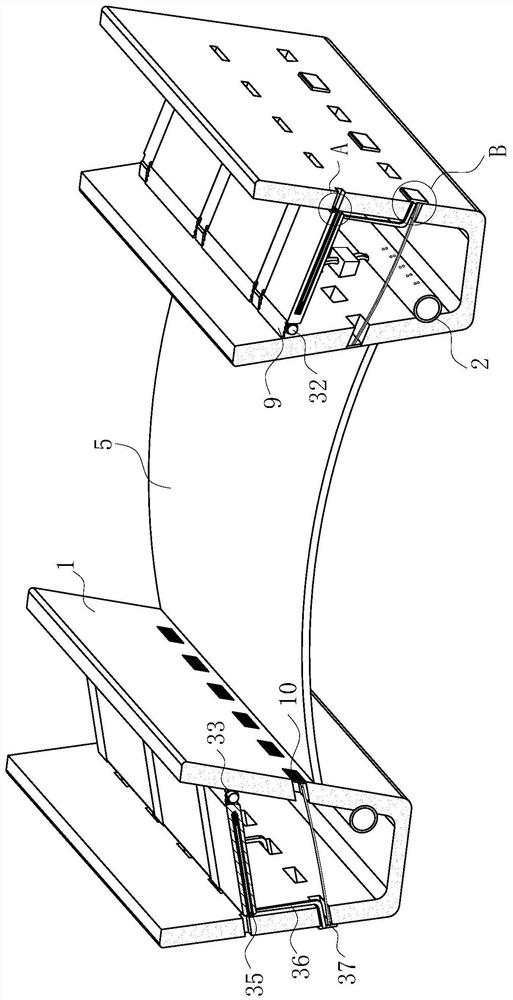

Image

Examples

Embodiment approach

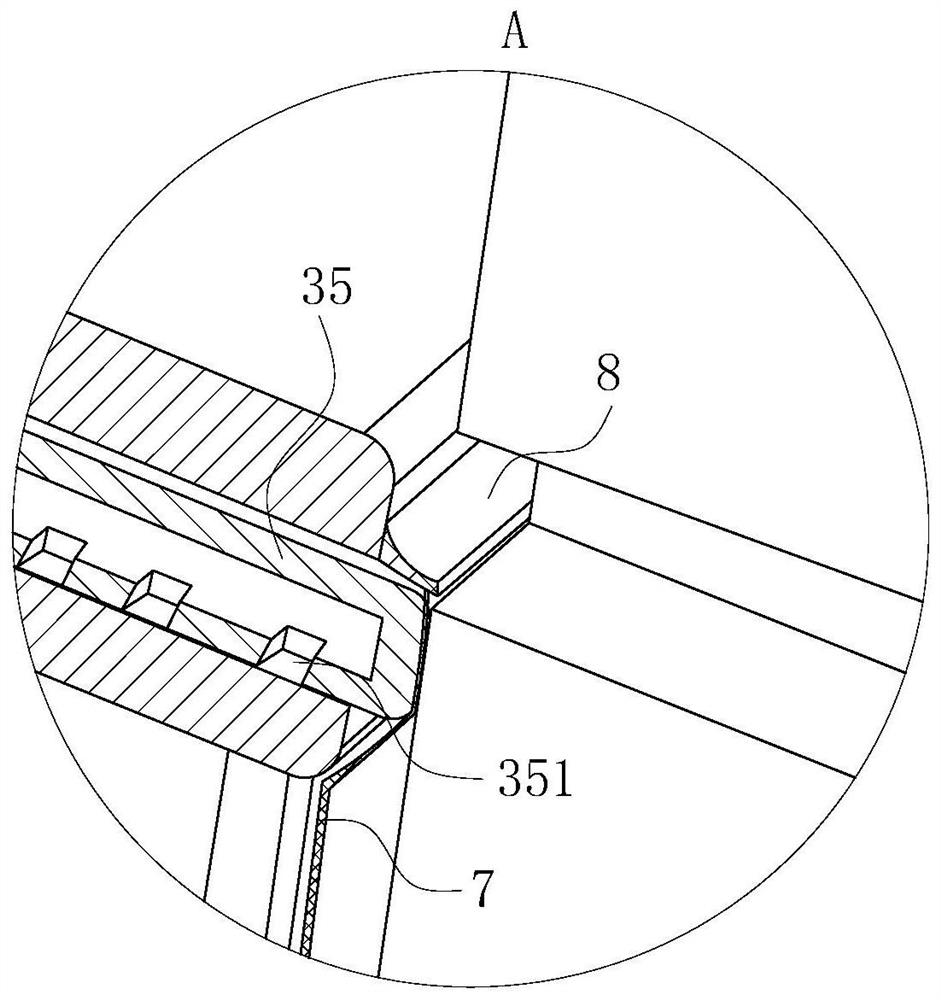

[0029] As an embodiment of the present invention, an elastic corrugated layer 9 is provided on the upper end of the inclined direction of the cavity rotating plate 34, and the elastic corrugated layer 9 is fixedly connected to the side wall of the isolated water channel 1; the elastic corrugated layer 9 is located above the torsion spring 33; during work, the elastic corrugated layer 9 provided can seal the torsion spring 33, and at the same time, the upper end surface of the cavity rotating plate 34 can be fully sealed; when the cavity rotating plate 34 under the torsion force of the torsion spring 33 is quickly attached to the side wall of the isolated water channel 1, the elastic corrugated layer 9 can elastically buffer the cavity rotating plate 34 to prevent the cavity rotating plate 34 from rapidly rotating When it hits the side wall of the isolated water channel 1, the phenomenon that the cavity rotating plate 34 is damaged is caused.

[0030] As an embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com